What is Sludge Dewatering and why is it used?

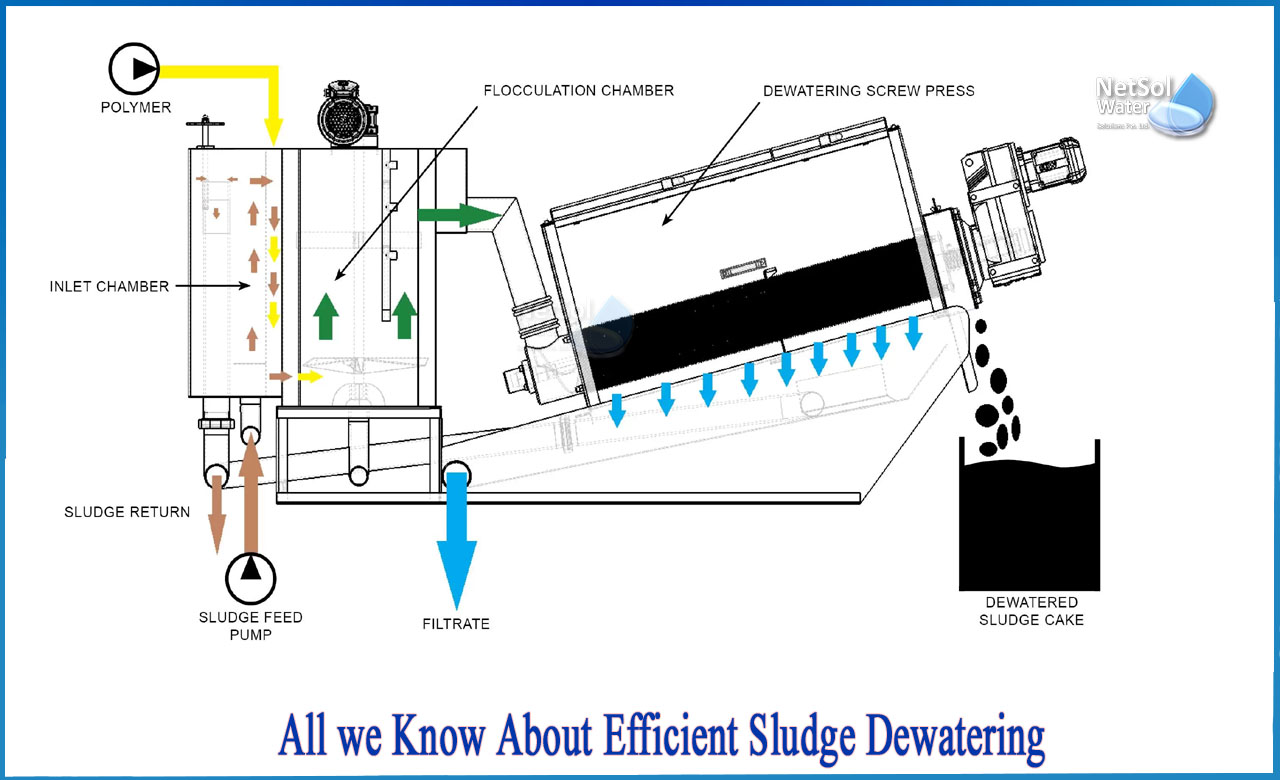

Sludge dewatering is the procedure of reducing waste volume in order to prepare it for successful disposal. Sludge is formed during the treatment of wastewater before it is discharged back into the environment. Sludge, a by-product recovered from slurry during the process of industrial or municipal wastewater treatment, has long been a source of concern for the water treatment sector. Before disposal, drying the sludge with a dewatering filter press greatly decreases its weight and volume.

Dewatering of sludge in an effective manner

1. Users should set the drainage line to have a consistent sludge flow rate (for example, to the centrifuge). It is crucial to deal with its consistent composition and concentration since these parameters are significant elements influencing the flocculants response.

2. Gradually lowering or increasing the flocculent dose at a fixed concentration will result in an increase or decrease in sludge dry matter.

3. You must always wait for this state to settle following a change.

4. Following that, samples can be collected and visual and laboratory results produced. In most circumstances, we want the sludge to have the maximum dry matter (high concentration of insoluble matter) and also to have the lowest concentration of insoluble matter (the liquid phase resulting from dewatering).

5. An appropriate flocculent dose may then be determined, but let me reiterate - for sludge of the same composition. For greater or lower sludge flow rates, the appropriate dosage can also be established.

Methods to improve the dewatering process

If a considerable amount of flocculent is required yet the pump capacity is at its limit, the solution concentration can be increased.

Simply add extra flocculent powder to the same amount of water at the point of solution formation. The flocculants solubility defines the limitations of such a setup. Unabsorbed clots will develop in the volume if the dosage is exceeded. It is also possible that the technique used is completely incorrect for your sludge. Its composition is intimately tied to the manufacturing processes. As a result, doing a pre-purchase assessment of existing facilities with identical output and products will never be ineffective. Water and sludge should be of comparable quality.

Advantage

It's worth considering if solar energy would be required in the future to treat the sludge from the WWTP in ways other than what we're used to. Because of their composition, some sludge’s, for example, are now burnt (dangerous substances and such).

The sludge spectrum that will be condemned for burning may include sludge from bigger WWTPs (primarily for phosphorus recovery) or wastewater treatment facilities where chemicals such as pharmaceuticals, heavy metals, or petroleum can be absorbed into the sludge.

As a result, it is prudent to carefully consider solutions that give the lowest weight and greatest dry matter, which will contribute to more efficient combustion and transport.

Netsol Water aims to use renewable energy.

For design, installation and manufacturing of waste water treatment plants or ETP’s or any other water related products, contact us.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.