What is a sequential batch reactor in wastewater treatment?

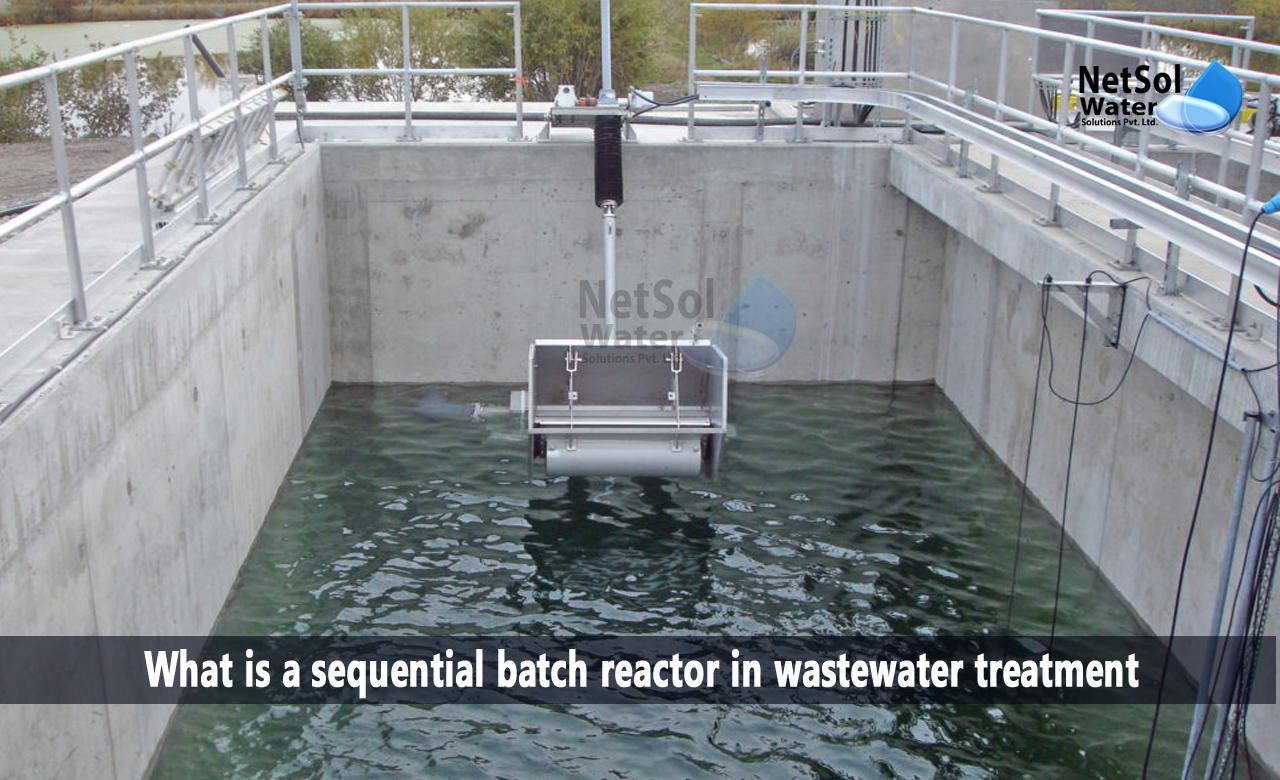

Sequential batch reactor or SBR systems in wastewater treatment are improvements, to traditional activated sludge systems that integrate various functions, into a single treatment system to reduce footprint.

Reactor basins, water sludge draw-off mechanisms, effluent decanters, and process control systems are frequently found, in standard sequencing batch reactor or SBR configurations.

Operation of Sequencing Batch Reactors

SBRs use a single fill-and-draw tank to process wastewater in batches. Five orders are used to operate each tank: fill, respond, settle, draw, and idle. In order to maximize the efficiency of their systems, some treatment facilities may use two or more batch tanks, depending on the anticipated amount of wastewater flow, and the length of the treatment process.

Before it reaches the reactor tanks, influent water that has passed through the SBR, is sent through a series of screening and grit removal operations. Each batch reactor is partially stocked with biomass by technicians, to speed up the anaerobic processes needed for water treatment.

Aeration, equalization, primary and secondary clarifying, as well as other procedures are carried out, inside batch reactors in a time-controlled order.

Use of sequential batch reactors

The use of SBRs eliminates a number of elements present in conventional activated sludge systems, such as primary sludge pumps and return activated sludge. In an SBR setup, technicians have more flexibility and control over the treatment processes, because they only concentrate on one sludge for each batch of wastewater they treat.

By eliminating organic compounds using a sophisticated solids handling system, which includes an aerobic digester and a thickener treatment facilities that use sequencing batch reactors, can greatly improve the quality of effluent flow.

SBR Industrial Applications

Due to the limits of their time-controlled processes, facility managers typically employ SBRs in low-flow systems.

In contrast to traditional activated sludge systems, SBRs need very little storage space. As a result, facilities can construct improved compound systems for a variety of sectors, by combining SBRs with additional reactors.

Wastewater treatment in SBRs

Sequential batch reactors may be used in sewage treatment facilities, due to their efficiency in handling particles in organic wastewater. According to research, SBRs are capable of efficiently destroying thermally hydrolysed sewage sludge.

Improvements to Anaerobic Digesters

Comparing an SBR system to traditional continuously stirred tank reactors, the former can offer more control and efficiency in anaerobic digester outputs.

According to studies, facilities can enhance control cycle time and discharge operations, while still meeting effluent regulations by adjusting influence factor values.

Treatment through Mechanical and Biological means

SBRs are used in normal biological treatment procedures like anaerobic digestion or waste separation, in mechanical biological treatment (MBT) facilities. MBTs might be crucial in the treatment of municipal biodegradable waste.

Biogas, recyclable goods like plastic and metal, and inert waste disposed of in landfills, are the most typical outputs of MBT operations.

Reagents used in sequential batch reactors

SBR performs a variety of functions, including biological processing and chemical oxidations, using a variety of reagents. The following are some examples of reagents:

• Fenton's Reagent, a sodium hydroxide solution with ferrous iron catalysts that is frequently employed, in wastewater treatment oxidization applications.

• Folin and Ciocalteu's phenol reagent: A substance to assess the amounts of protein in wastewater treatment processes, using aerobic sludge granulation.

• Pyruvate Oxidase: A biomarker for phosphate concentration monitoring.

What do we offer?

Now, we know that SBR systems are improvements to traditional activated sludge systems, which integrate various functions into a single treatment system to reduce footprint.

To assist you with this process, Netsol Water provide a wide range of water and wastewater treatment plants. For further information or to make a purchase, please contact us at +91-9650608473 or enquiry@netsolwater.com