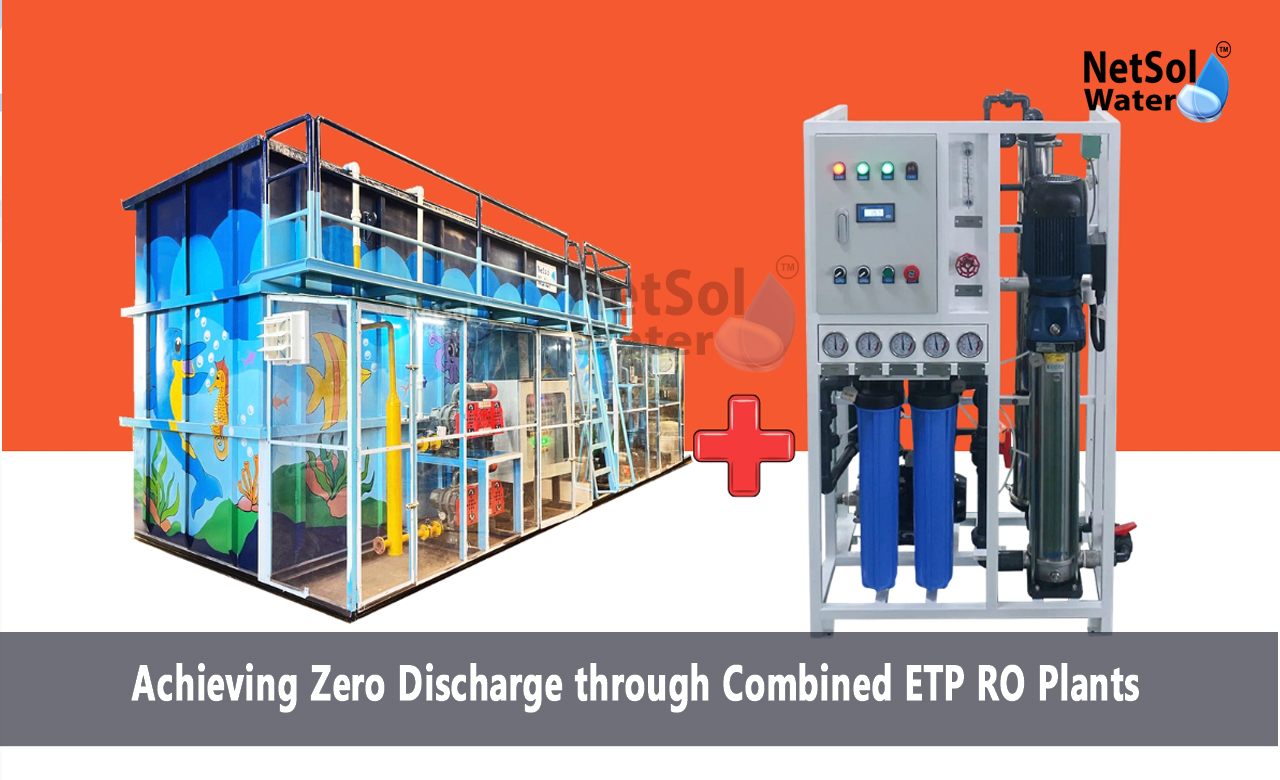

How to Achieve Zero Discharge through Combined ETP-RO Plants?

With the growing trend of environmental conservation, various industries have begun seeking methods of reducing their impacts on the environment. Among these, one of the most important areas where industries can actually make a huge impact is the integration of zero discharge principles in wastewater treatment policies. The purpose of this blog post is to explain the idea of being able to reach zero discharge by implementing combined ETPs and RO plants. Thus, by studying the technology and how it can be implemented, industries can go a long way in addressing their discharge and preserving the environment.

What is Zero Discharge?

Zero discharge means that there is no direct discharge of wastewater or effluent from an industrial facility into any environment. However, as a conservation and recycling centre, the utility facility recycles or re-uses its wastewater or discharges it back into the production line. The overall objective is to save water, lower the application of fresh water, and bring down the environmental impacts of industries.

Combined Effluent Treatment Plants (ETPs)

Effluent treatment plant means the treatment of examined water, which is provided by some industries, before it is released to the environment for disposal. Physical, chemical, and biological methods are applied in ETPs to treat the contaminants and pollutants present in the derived wastewater. A system where more than one ETPs is used so as to improve the efficiency of the treatment of the wastewater.

Key components of a combined ETP include

1. Primary treatment: In this process water and the dissolved pollutants are allowed to flow separately from the settled larger particles or solids. Sedimentation tanks also known as clarifiers provide a practical solution for this need.

2. Secondary treatment: Suspended growth systems use biological process to precipitate dissolved organic matter and nutrients – nitrogen and phosphorous. Some of the most common secondary treatments include activated sludge, trickling filters, anaerobic digestion among others.

3. Tertiary treatment: It also excludes more contaminants such as heavy metals, pharmaceuticals and other micro-pollutants next to those neutralized by CO2. Tertiary treatment options include membrane filtration, ion exchange, and Advanced Oxidation Process, etc.

4. Sludge treatment: Waste produced by the ETP is in the form of solid waste which should be well disposed. Some of the common sludge treatment processes include the following; Sludge stabilization and conditioning sludge dewatering, and Sludge land filling.

Reverse Osmosis (RO) Plants

Reverse osmosis is the process of forcing water through a semi permeable membrane to loosen dissolved salts, particles and other pollutants. Our research is focused on the using of RO systems in the water treatment, more specifically in the field of wastewater reuse and in desalination of seawater.

Key components of an RO plant include

1. High-pressure pump: In order to overcome this osmotic pressure and pressure the water through the membrane.

2. Pre-filters: These filters help to eliminate large particles and also suspended solid to avoid foucing of the RO membrane.

3. Semi-permeable membrane: Membrane is the central component of RO system and its main purpose is to let the water molecules to pass through while rejecting contaminants.

4. Post-treatment: Further treatment on the purified water involves a process such as pH correction, water disinfection, and water remineralization in order to be used in the production process.

Reduction and Elimination of Zero Discharge using ETPs and Reverse Osmosis Systems

For them to obtain zero discharge status, industries must therefore embrace both the combined ETPs and RO plants in their operations. The following steps outline the process:

1. Assess the current wastewater generation and treatment capacity: The first strategy is based on the assessment of current practices related to wastewater generation and treatment to determine opportunities for optimization and integration of RO plants.

2. Design and install a combined ETP: From the evaluation undertake a proposal for a combined ETP that will suit the needs of the industry. This system should therefore contain primary and secondary treatments and tertiary treatments and sludge management.

3. Integrate RO plants: After the implementation of the ETP, the best approach is to incorporate RO plants for the subsequent purification and recycling of water. The RO plant has to be effective in treating the effluent discharge to the ETP to ensure that it is safe for the company’s reuse such as in production processes.

4. Monitor and maintain: The appropriate operational control of the ETP as well as the RO plant is necessary; failure to which may lead to polluting the environment.

5. Implement water conservation measures: The industries should also adopt similar water conservation practices such as process modification, water analysis, and detection of leakages in a bid to cut on the use of fresh water.

Advantages of Reaching for Zero Discharge

The adoption of zero-discharge policies through the use of combined ETPs and RO plants offers several benefits, including:

1. Reduced environmental impact: Reducing the discharge of wastewater as much as possible or even avoiding it strongly contributes to the prevention of the detrimental impact that industries have on the environment.

2. Water conservation: Using treated wastewater streams decrease the reliance on freshwater resources and it supports water management.

3. Cost savings: This saves the industries money used in procuring fresh water and also the money that is used in treating the water.

4. Regulatory compliance: Zero-discharge policies are in tandem with the stringent environmental laws governing economic sectors and regulatory codes from different authorities to check compliance.

Conclusion

Reducing ETPs discharge through integrated systems and attaining RO without any discharge is a noble way of practicing sustainability. Employing such measures, industries can help in saving water, minimizing negative effects on the environment as well as play the part in the conservation of earth’s scarce resources. Overall, these technologies if properly planned, designed, and implemented can be effectively incorporated by industries for wastewater management and the door to a sustainable future will be clearly open.

Do you need an advice or assistance on selecting the best water and waste water treatment unit? We have solutions for all your problems!

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.