What is the reason behind White and Frothy foam in Aeration of ASP?

Foam is a collection of small gas bubbles that form on the surface of a liquid, such as the froth created by agitating a soap or detergent solution in water.

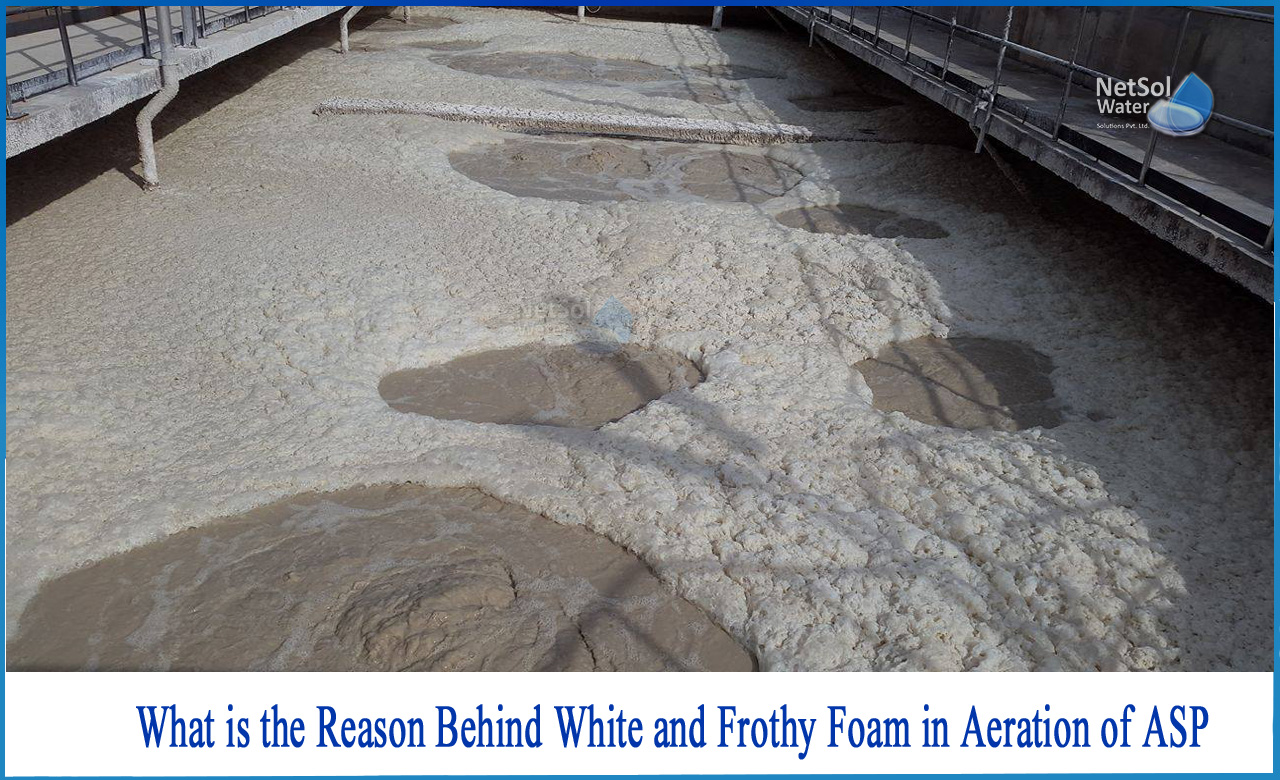

In many wastewater treatment plants, foaming in the activated sludge process is a typical operational issue. The foam inside the aeration tank is generally divided into chemical foam and biological foam, which can greatly reduce the oxygenation capacity.

a) Foam can form in the aeration tank, the secondary clarifier, and the anaerobic digester. Typically, WWTP foam is sticky, viscous, and dark in colour.

b) It floats and gathers on top of the tanks, taking up a significant portion of the solids inventory and reactor volume, reducing effluent quality and sludge retention time control (SRT).

c) The foam can also overflow onto walkways and other nearby places, posing both operational and environmental risks.

Different colors of foam help us to determine different growth stages of activated sludge!

In this article we will talk in detail about the causes of white frothy foam during aeration.

Causes of white and frothy foam

Foaming and bulking problems in ASPs have been linked to the presence of a variety of filamentous bacteria, and the causative agents of filamentous bulking and foaming have been discovered. Sphaerotilus spp. and Leptothrix spp., Microthrix parvicella, Corynebacterium, Dietzia, Gordonia, Skermania, Mycobacterium, Nocardia, Rhodococcus, and Tsukamurella, are the primary organic degraders in situ, providing the skeletal matrix for the production of compact flocs.

Causes of Foaming

Foaming can occur for a variety of reasons, including the presence of slowly biodegradable surfactants in industrial or municipal wastewater, excessive production of extracellular polymeric substance (EPS) by activated sludge microorganisms under nutrient-limited conditions, proliferation of filamentous organisms, and gas supplied in aeration tanks or produced in the anoxic zone of aeration tanks, secondary clarifiers, and anaerobic.

In a WWTP, stable foaming is the result of interactions between gas bubbles, surfactants, and hydrophobic particles. At the air-water contact, the hydrophobic particles aggregate and strengthen the water film between air bubbles. Meanwhile, the particles operate as a surfactant collector, which helps to keep the foam stable.

Aeration, mechanical mixing, and biological processes such as denitrification and anaerobic digestion all produce gas bubbles in a WWTP. Surfactants in WWTPs come from wastewater streams containing surfactants that degrade slowly; hydrophobic particles are filamentous bacteria with a long chain structure and a hydrophobic surface.Foaming is caused by wastewater containing slowly degradable organic material such as lipids, proteins, and fats that filamentous microbes prefer to use.

So the stiff white, billowing foam, are caused by excessive activated sludge load, increased aeration and inflow of detergents. White foam is an indication of sludge found in either a new plant or an overloaded plant. This indicates a low MLSS concentration with a high FM.

How can Netsol Water help you?

We have expertise in wide range of wastewater treatment technologies. We can customize wastewater treatment plants that will cater to all your needs and at the same time effectively treat different types of wastewater.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.