How does a septic tank works?

The most common small-scale decentralised treatment unit for grey and blackwater from cistern or pour-flush toilets is the septic tank. It's essentially a sedimentation tank. It can be rectangular or cylindrical in shape.

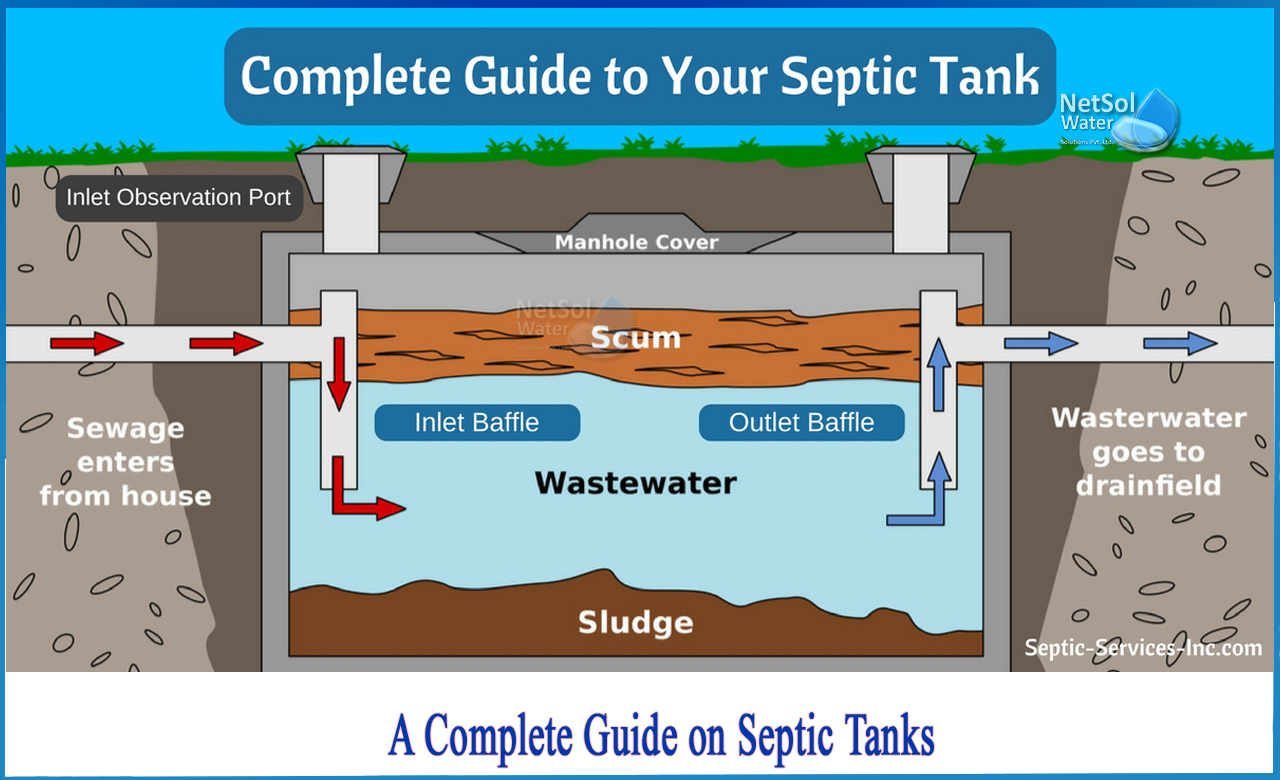

Septic tanks are typically used for wastewater with a high settleable solids content, such as effluent from domestic sources, but they are also suitable for other wastewater with similar properties. Heavy particles sink to the bottom of the tank as liquid flows through it, while scum (mostly oil and grease) floats to the top. Solids that settle to the bottom are degraded anaerobically over time.

However, the rate of accumulation outpaces the rate of decomposition, and the accumulated sludge and scum must be removed on a regular basis. Septic tank effluent must be dispersed using a Soak Pit, evapo-transpiration mound, or Leach Field, or transported to another treatment technology using a Solids-Free Sewer or simplified sewer. Surface flow, horizontal or vertical flow constructed wetlands) are suitable for secondary treatment.

Sludge must be emptied on a regular basis (human-powered or motorised emptying) and treated before it can be safely disposed of or reused. It can be dried in either planted or unplanted drying beds, as well as in settling or thickening ponds. If the sludge is dried or composted, it can be used as a valuable nutrient-rich soil amendment in agriculture. There are also several new methods for producing fertiliser from sludge.

Septic tanks are typically followed by anaerobic filters, anaerobic baffled reactors, horizontal, surface flow, or vertical flow constructed wetlands (planted gravel filters), and maturation ponds as primary settling treatment systems.

Chambers in septic tank:

A septic tank must have at least two chambers made of concrete or brick chambers. Pre-fabricated concrete rings, PVC or fibreglass septic tanks, and other options are available and may be less expensive. When there are only two chambers, the first chamber should be at least 50% of the total length, and it should be two-thirds of the total length when there are only two chambers.

The majority of the solids settle in the first chamber. The purpose of the baffle, or the separation between the chambers, is to keep scum and solids from escaping with the effluent. A T-shaped outlet pipe, the lower arm of which dives 30 cm below water level, reduces the amount of scum and solids discharged even further.

Different treatment effects predominate depending on how the new influent flows through the tank. The degradation of suspended and dissolved solids begins more quickly in a turbulent flow; however, more suspended solids are discharged with the effluent. This causes bad odours because active solids that have not been completely fermented leave the tank.

When the flow is less turbulent, contact and thus degradation are slower, but less suspended solids leave the tank. It is necessary to allow the gases produced during anaerobic digestion to escape. Gases from the septic tank can escape along the drains if the drainage system of the house or other building has a ventilation pipe at the upper end. If the drainage system is not ventilated, a screened vent pipe from the septic tank should be installed.

Advantages of septic tank:

- Can be constructed and repaired using locally available materials

- If used correctly, there should be no flies or odours

- Technology that is simple and robust

- There is no need for electrical energy

- Because of the underground construction, there is little space required

- Low operating expenses

- Service life is extended

- Requires a small amount of land

For more information, contact Netsol Water.