What are the parameters to keep-on-check in of RO Process?

The silt density index (SDI), differential pressure, normalised permeate flow, percent rejection, and pressure drop coefficient are the five most critical indicators to monitor on a regular basis. They show the fouling potential as well as the level of fouling and/or scaling, which are the two main causes of membrane element replacement prematurely.

1. Silt Density Index is a measure of the amount of silt (SDI)

The SDI is a measurement of suspended particles and colloidal’s in feedwater taken on-site. It's utilized to keep track of how well the pretreatment equipment is working.

Pre- and post-multimedia filters, carbon filters, and post-cartridge filters should all be used to perform SDI measurements. Backwash of the equipment prior to the RO and replacement of the cartridge filters should be efficiently regulated using the prescribed flow rates and differential pressure limitations to give SDI of less than 3.0 before employing the membranes.

Filter aids can help reduce SDI before multimedia filtration, resulting in higher filter efficiency. Professionals, on the other hand, should exercise caution while using cationic filter aids.

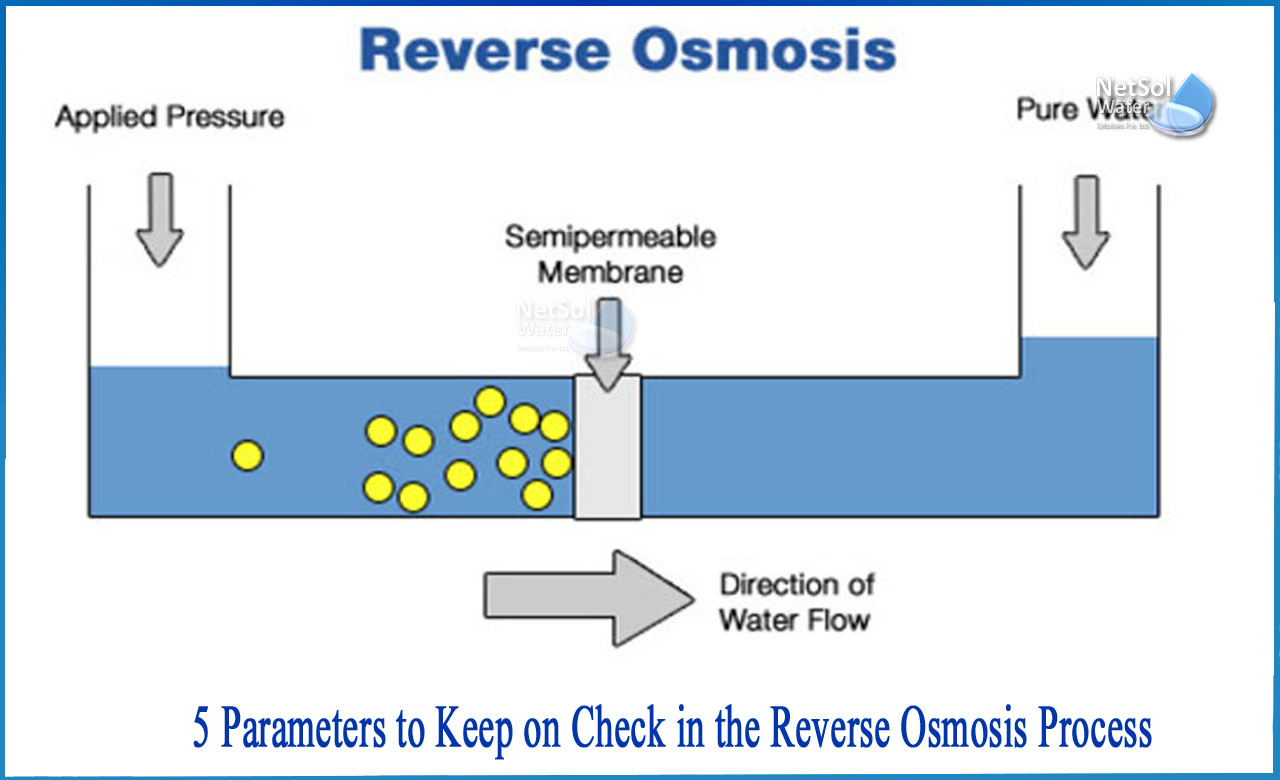

2. Pressure drop in reverse osmosis systems

The water is pushed over the membrane surface of all the elements by the difference between the inflow to the starting membrane elements and the concentrate stream pressure emerging off the tail end elements. The pressure drop, also known as the hydraulic differential pressure (P), is the result of this.

Unless something physically stops the passage of flow between the membrane envelopes of the elements, the ‘P’ will not change as long as the fluxes and temperature remain constant (fouling). As a result, it's critical to keep an eye on the ‘P’ at every stage of the process. An increase in P can then be traced down to the front of the first stage, the lead membrane, the last stage at the tail end, or both to determine the source. Particle/colloids, organic, microbiological, or coagulant/polymer fouling could be the reason of a rise in pressure in the first stage.

3. Permeate flow has been normalised

In RO systems, normalized permeate flow is one of the most sensitive predictors of difficulty. The rate of permeate flow can be slowed by fouling. However, monitoring the permeate flow rate alone is insufficient because it is affected by feedwater temperature, feed pressure, permeate pressure, and feedwater conductivity (total dissolved solids, or TDS). Despite the fact that all RO membrane manufacturers have their own algorithms for calculating normalized permeate flow, this difficult calculation requires multiple parameters: temperature, net driving pressure, pressure drop, permeate, feedwater TDS, and permeate flow.

Temperature and pressure variations are taken into account in this calculation. Normalized permeate flow is a formula that adjusts daily data readings to what they would be if the system was running at starting pressure at 25°C.

4. Rejection rate in percentages

The permeate TDS is monitored using percent rejection. Many facilities do not monitor TDS, therefore measuring feedwater and permeate water conductivity is the simplest technique to evaluate salt rejection. The percentage of TDS (conductivity) rejected by the RO is referred to as percent rejection. When RO membranes fail, the % rejection drops, and the permeate conductivity rises. Certain foulants, on the other hand, can clog the membrane and raise the % rejection value.

5. Monitoring PDC

The data from reverse osmosis processes is monitored in most RO plants. This information is useful for forecasting the unit's performance. When the Pressure Drop Coefficient (PDC) versus P is normalised, it becomes one of the greatest ways to trend data:

It is widely acknowledged as a best practise in the reverse osmosis sector for monitoring when to clean:

• The normalised permeate flow decreases by 10%.

• Salt passage rises by 5–10%.

• A ten to fifteen percent decline in pressure.

• PDC increases by 10% to 15%.

What do we offer?

If you want to know more about the parameters of RO Water and RO Plant installations, then you are at the right place!

You can have an expert solution upon contacting Netsol Water Solutions, a leading manufacturer of Industrial and Commercial Water treatment plants and Wastewater treatment plants, among other services. Our treatment systems are very effective at removing all types of chemical, physical, and biological pollutants.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.