What is ZLD in wastewater treatment?

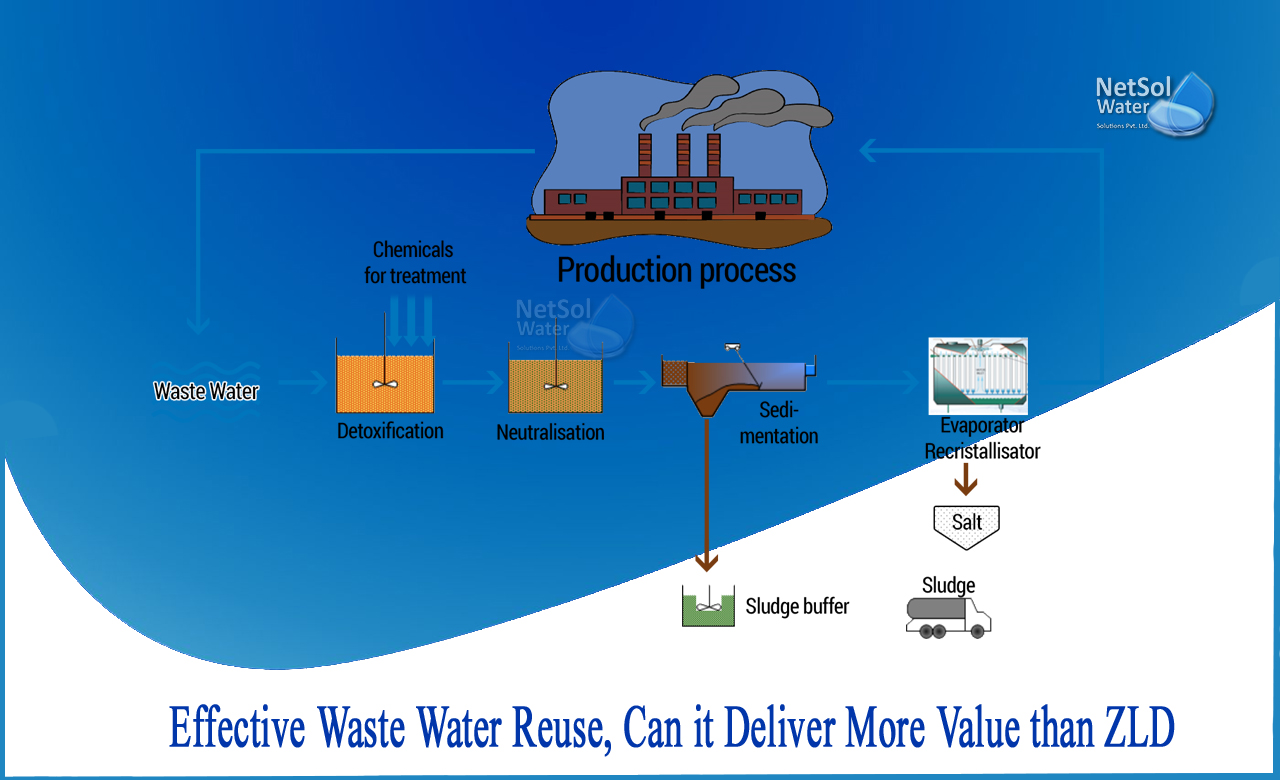

The term "zero liquid discharge" (ZLD) refers to a treatment procedure in which the facility releases no liquid effluent into surface waterways, thus removing all environmental pollutants associated with treatment.

Aside from this advantage, a ZLD process effectively utilizes wastewater treatment, recycling, and reuse, therefore contributing to water conservation through lower consumption of fresh water. ZLD is not only a successful technology, but it also presents obstacles in the treatment of a wide range of process industries, including bulk medicine manufacturers, textile factories, and chemical and fertilizer plants.

Creating zero discharge solutions is possible by concentrating effluent using different approaches, such as membrane-based and multiple effect evaporation-based systems, as well as water recovery and recycling.

ZLD's Benefits

a) ZLD is an efficient way to assure regulatory compliance, restore natural water resources, and safeguard the environment.

b) Zero Liquid Discharge is the more ambitious of the two wastewater management strategies.

c) It recovers nearly 100 percent of the water for reuse and eliminates any liquid waste that leaves the plant.

Despite the numerous benefits of ZLD, large-scale application of the procedures has been hampered by high prices due to the energy required in the classical thermal methods utilized in ZLD.

Traditional thermal methods are evolving

Industrial enterprises looking for wastewater treatment solutions have a potent weapon in Zero Liquid Discharge (ZLD).

ZLD filters and recycles all wastewater using modern processes such as ultrafiltration, reverse osmosis, evaporation/crystallization, and fractional electrode ionization, resulting in zero discharge at the end of the treatment process.

ZLD goes beyond fundamental standards and offers an expensive answer to a variety of problems. –

- Dwindling water resources

- Inadequate quality of incoming water supply

- Regulations enforcing strict discharge limits

- Initiatives to Go Green

- Quality of rinse water

Unfortunately, many firms do not understand that realistic water recovery/reuse may efficiently service the demands of their facility more economically than ZLD until they have made a major capital investment.

Recovery of low-TDS simple water

ZLD may be the most practical choice for businesses that do not have a close disposal point, whose source water requires extensive treatment, or whose activities necessitate more water than can be purchased.

ZLD provides 100 percent water recovery, does not require a discharge permit, and requires minimum trash transport off. However, not every business requires the therapeutic benefits that ZLD delivers. Water recovery rates range from 70% to 85% when practical water reuse is used. A permit is required since there will be some waste discharge. This technology enables for the recovery of waste water with a low TDS (Total Dissolved Solids).

Conclusion

Each industrial manufacturer's specific scenario defines which kind of wastewater treatment gives the best option.Before investing in a treatment approach, it is critical to contact with an expert to discover which method provides the most value. Financially, the cost ratio for ZLD's capital and operating expenses is three times the cost of treatment and discharge, but the practical water reuse technique is just 1.5 times the cost.

Water reuse is practical for cost-conscious businesses that discovers that they can save money by reusing treated wastewater. This technique maximizes water recovery while lowering capital and operating expenses. However, wastewater has shown to be a highly useful, ecologically sustainable resource when and where it is properly handled. Practical water reuse assists businesses in saving money and being green in order to become better corporate citizens.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.