Working principle of ETP Plant for Galvanized Plant for GI Pipe

Effluent Treatment Plant (ETP) is an essential component of the Galvanized Plant for GI Pipe Industries, which is designed to treat and purify the wastewater generated during the manufacturing process. This plant helps to remove the harmful contaminants and pollutants from the wastewater before discharging it into the environment.

In this blog, we will discuss the working principle of the Effluent Treatment Plant for Galvanized Plant for GI Pipe Industries, its function in detail, and the process flow diagram.

Working Principle of Effluent Treatment Plant:

The Effluent Treatment Plant (ETP) for Galvanized Plant for GI Pipe Industries works on the principle of physical, chemical, and biological processes. The wastewater generated during the manufacturing process is collected in a collection tank, from where it is pumped to the Effluent Treatment Plant. The wastewater undergoes a series of treatment processes, as discussed below:

-

Screening and Grit Removal:

The first step in the treatment process is the screening of the wastewater to remove large solids and grit. The wastewater passes through a screen, which removes the larger solid particles, and then passes through a grit chamber, which removes the grit and sand particles.

-

Equalization Tank:

The screened wastewater is then stored in an equalization tank, where it is homogenized and mixed to ensure a consistent flow rate to the treatment process.

-

Primary Treatment:

The wastewater then flows into a primary treatment tank, where the suspended solids settle to the bottom of the tank, and the oil and grease float to the top. The settled solids and floating oil and grease are then removed using skimmers and scrapers.

-

Biological Treatment:

After the primary treatment, the wastewater flows into a biological treatment tank, where it undergoes a process called activated sludge. In this process, microorganisms break down the organic matter in the wastewater, converting it into harmless by-products such as carbon dioxide, water, and biomass.

-

Secondary Treatment:

The wastewater then flows into a secondary treatment tank, where the remaining suspended solids and dissolved organic matter are further treated. This process is called the Extended Aeration Process, and it involves the use of air to provide oxygen to the microorganisms, which further breaks down the organic matter.

-

Tertiary Treatment:

The final step in the treatment process is the tertiary treatment, where the wastewater is further treated to remove any remaining contaminants and pollutants. This process involves the use of chemical coagulants, flocculants, and sand filters to remove any remaining impurities.

-

Disinfection:

The treated wastewater is then disinfected using ultraviolet light or chlorine to kill any remaining bacteria and viruses.

-

Sludge Management:

The sludge generated during the treatment process is removed and transported to the Sludge Treatment Plant for further processing.

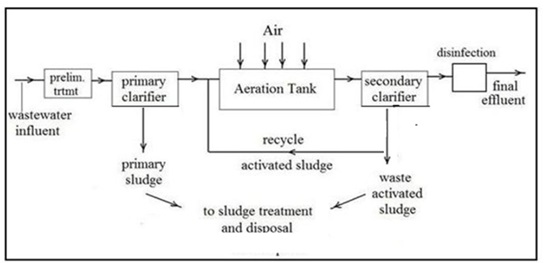

Process Flow Diagram and Drawing:

The process flow diagram of the Effluent Treatment Plant for Galvanized Plant for GI Pipe Industries is shown below:

Conclusion:

The Effluent Treatment Plant (ETP) for Galvanized Plant for GI Pipe Industries is an essential component that helps to treat and purify the wastewater generated during the manufacturing process. The treatment process involves a series of physical, chemical, and biological processes that remove the harmful contaminants and pollutants from the wastewater, making it safe for discharge into the environment. The Process Flow Diagram and Drawing provide a clear understanding of the various stages involved in the treatment process.

Call Netsol water at +91-9650608473 or send an email to enquiry@netsolwater.com to know more.