The most common way to remove turbidity from water is with Pressure Sand Filters or PSF. Multiple layers of sand with different sizes and particular gravities make up the Pressure Sand Filter. These filters are made to eliminate turbidity and suspended particles from feed water, with the least amount of pressure loss possible.

These filters are available with face piping, related valves, and either mild steel, FRP, or stainless steel construction.

Let’s discuss about the working of pressure sand filters (PSF) in this blog.

What is a pressure sand filter?

A depth filter that uses a set ratio of coarse and fine media is called the Pressure Sand Filter or Multigrade Sand Filter. This configuration creates a filter bed with sufficient pore size to hold, both large and tiny suspended particles.

Compared to traditional filters, this filter operates at a significantly greater specific flow rate. For treating water with 50–25 ppm suspended solids, a specific flow rate of 15–30 m/hr has been effectively achieved, resulting in a filtrate with less than 5 ppm. The treated water from this range of filters will have 2 NTU turbidity. Also, it can manage feed water up to 25 NTU turbidity.

Working of Pressure sand filters (PSF)

1: Water is passed through multiple layers of graded sand, pebbles, and gravel layers in a pressure sand filtration.

2: The media bed in the water filters the contaminants, and the filtered water then enters the discharge manifold, at the base of the containers.

3: Backwashing is the last and final stage, which involves removing contaminants that have been successfully captured from the media bed.

4: After being back-washed, the filter is rinsed with raw water and then put back into service once the necessary level of water quality is reached.

Construction of a Pressure Sand Filter (PSF)

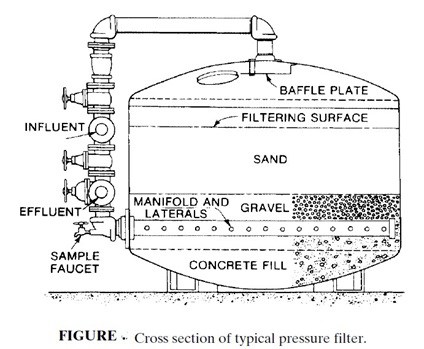

PSF is a closed structure made up of a cylindrical tank with several brass strainers at the bottom. These are attached to a manifold that is set into concrete or fixed on a false bottom. The strainers have been sawed with thin slots. The top is covered with a layer of gravel that is fairly coarse. Sand is layered 6 to 12 metres above this, serving as a filtration medium. To avoid disturbing the sand with a direct stream, baffles are placed at the feed inlet site. The filter collection is provided at the bottom.

The feed is delivered at pressure through the baffle from the top of the pressure sand filter. Onto the sand medium, the feed is easily and uniformly passed. By using a straining device through the sand medium, filtering is accomplished. The feed is then run through the strainer for additional filtering, retaining the particles. Then, the sediment is thrown away. The bottom is where the filtrate is gathered.

Backwashing in Pressure sand filters

It enables the regeneration of the filter bed when the precipitate clogs the sand which is indicated by a decreased filtering rate. Water flows out of the inlet and up through the sand layer during this process.

Key characteristics of Pressure Sand Filter

· MOC for Effective Turbidity Removal – FRP, MSRL, MSEP, & SS

· Multi-grade sand material that is common and efficient

· Pressure decrease across the vessel

· Automatic, Semi-Automatic, and Manual Choices

· More rapid particular velocity

· It can be backwashed with raw/fresh water

· Greater specific flow rate than typical down flow filters, which conserves room and money

· Very little upkeep is necessary

· Lower water usage for backwash

· It is corrosion-resistant and requires less maintenance

· It is user-friendly & simple to work thanks to the single lever multiport valve

Applications of pressure sand filter

· It is widely used in the side stream filtering process for treating potable water.

· It's perfect for filtering purified water.

· It can also be used for the filtration of chemical liquids and sea water. Filters with rubber linings or epoxy paint can be provided for these kinds of filtration.

· It is used as a pre-treatment for the Reverse Osmosis plants.

· In housing communities, hotels, and retail centres, drinking water is first treated using PSF filters.

· Swimming Pool Filtration in Hotels and Housing Communities.

· Cooling tower and burner feed pretreatment.

· Boiler feed or water that is used for similar reasons is filtered using a pressure sand filter.

· For handling a big volume of feed and little to no solids, sand filters are typically employed.

Are you still confused about the working of PSF or pressure sand filters for the treatment of water and wastewater?

Netsol Water is the leading manufacturer, supplier, and exporter of a quality selection of water treatment and wastewater treatment plants in India. We provide a wide range of services to businesses including automotive, beverages, pulp & paper, textile, pharmaceutical, refineries, etc.

Call us at +91 9650608473 or email at enquiry@netsolwater.com for further information.