Dust particles are large enough or appear black enough to be seen, while others are so little that they are invisible. Dust collection may be required if you can see, taste, or smell particles in the air.

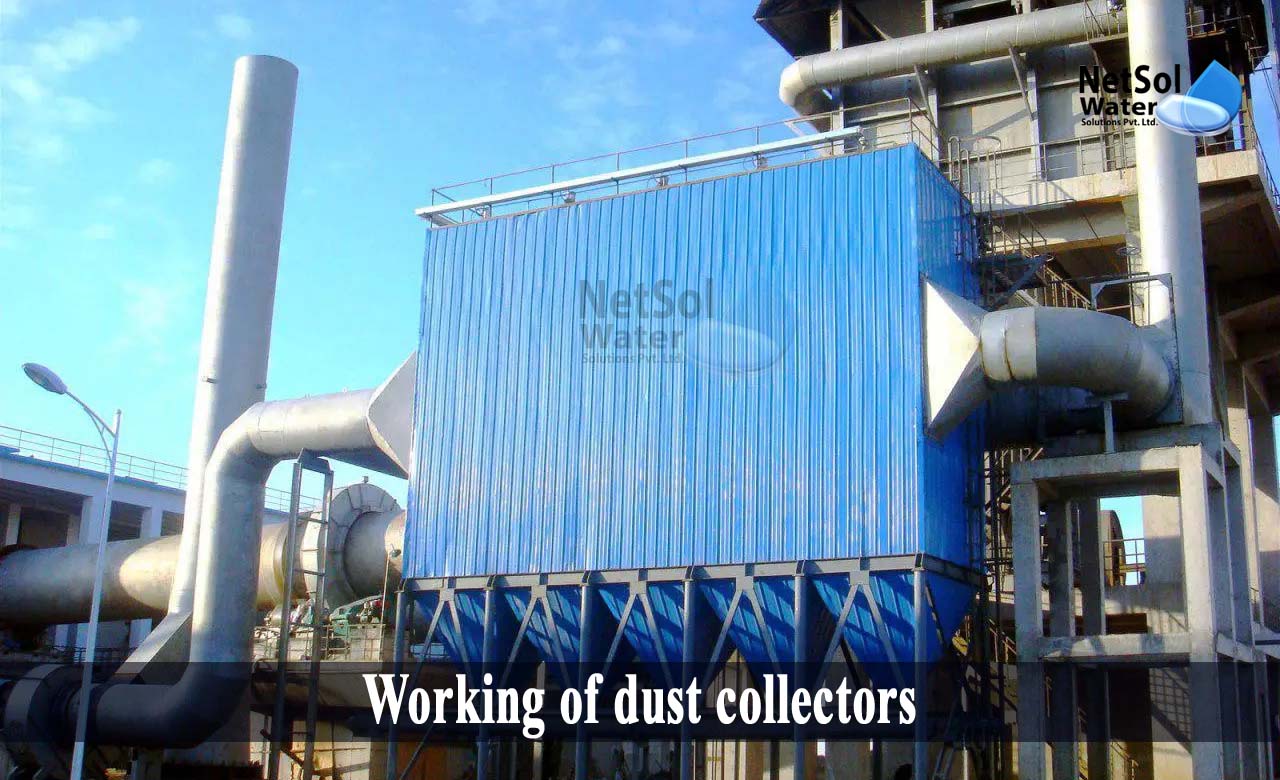

In this blog, let us understand the working of dust collectors.

What is the working mechanism of a dust collector?

Phase 1: Capture and transition step

This is the dust concentration stage.The dust is equally mixed or suspended in the carrier medium, and enters the dust collector's dust removal chamber.The dust is transported to the separation interface by the operation of external force.

The concentration of dust grows as it moves to the separation interface, necessitating further solid-gas separation procedures.

Phase 2: Separation

There are two action mechanisms when high concentration dust moves to the separation interface:

1: First, the carrier medium's ability to carry dust has progressively reached its limit. It is primarily sedimentation that separates dust from the carrier medium, in the trend of dust suspension and sedimentation.

2: Second, in the high concentration dust flow, the diffusion and agglomeration trend of dust particles is mainly agglomeration, and the particles can agglomerate with each other or agglomerate and adsorb on the medium interface.

Phase 3: The dust removal procedure

The separated dust is expelled through the dust output after passing past the separation interface.

Phase 4: Process of exhaustion

After dust removal, the comparatively cleansed air flow is evacuated via the exhaust port.

Dust collection systems & their working

· Shaker Dust Collectors

When the airflow is briefly halted, the system either cleans off-line or divides the baghouse into segments. A compartmented design allows for ongoing cleaning of the device, while also allowing individual compartments to be removed for servicing.

These machines are prevalent in industries where it is impracticable, to supply compressed air for bag cleanings, such as foundries, steel mills, mining, power plants, and smelting. They are also utilized in silos and other bulk storage containers, where dry material is stored.

· Pulse Jet Dust Collectors

They are another type of baghouse system that comes in a range of configurations, to satisfy the industry's application needs. The bag cleaning system uses a high-pressure air jet cleaning system, which sends a blast or shock of air through the bag, shatters it, and discharges the dust cake for disposal.

Because, of the quick pulse of air, the system may operate continuously with the fan operating, and it is not normally segregated.

· Cartridge Collectors

Cartridge collectors are a type of fabric filter that is developed for specialized uses. They are advantageous when less area is required for the same airflow, as a bigger baghouse system.

Cartridge collectors compress more fabric area into a smaller space, use fewer filters, and change filters from outside the collector, reducing safety dangers. These characteristics help lower the time required to change the filters, as well as the associated labour costs.

· Cyclone Dust Collectors

Cyclone dust collectors are a form of the inertial separator that uses centrifugal force, to filter dust from a gas stream. The cyclonic activity within the cyclone collection chamber purifies the air.

A powerful circular airflow, similar to a vortex, forces the dust particles against the cyclone's wall, where they slide down to the hopper's base for collecting. Heavy and large particles mixed together with fine dust, can be removed by cyclone systems. They are frequently used as pre-cleaners prior to baghouses.

· Electrostatic Precipitators

Electrostatic precipitators use static electricity to remove soot, ash, and dust particles from exhaust fumes. Electrostatic forces negatively charge airborne particles as they move across an ionized field, between electrodes within a chamber, similar to an ionic air cleaner.

When the particles are charged, they are caught by a positively charged electrode. Electrostatic precipitators can be used in industrial power plants that use fossil fuels, like coal and oil.

How can we assist?

Netsol Water provides service for dust collectors that require maintenance or retrofit. Our dedicated technical services section can repair or upgrade any make, model, or kind of industrial dust collector system.

Our expert team is well-equipped to assist you in selecting the best dust collection system for any application, enhancing the performance of filters and other machine elements.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.