What is filter press?

A filter press is one of the most well-known and reliable types of dewatering equipment. It's employed in a range of industries and applications for wastewater treatment. A filter press removes pollutants and suspended sediments from industrial effluent by separating solids from liquids. This makes it simple for plant managers to handle and dispose of trash while yet returning clean water to their systems.

Liquids and solids are separated using filter presses. Specifically, the filter press uses pressure filtration through a filter media to separate liquids and solids. The slurry is then poured into the filter press, where it is dewatered under pressure.

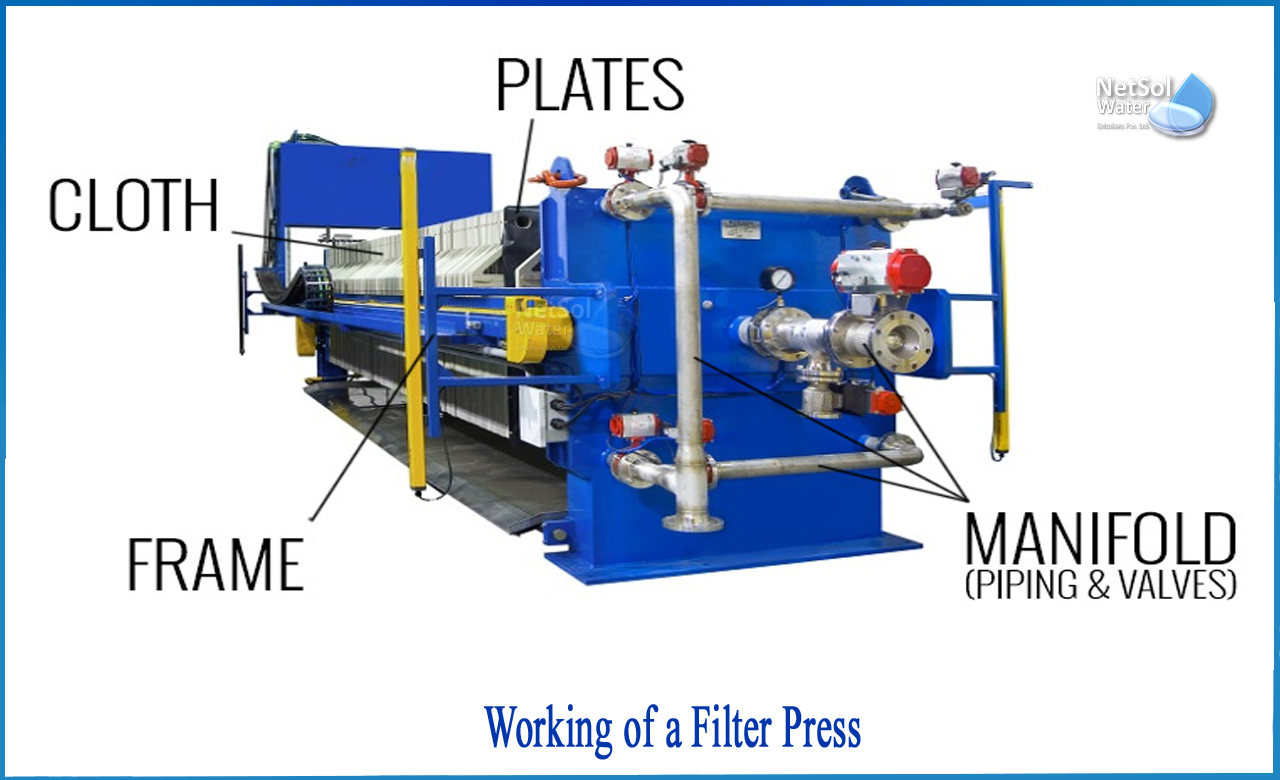

What are the Four Main Filter Press Components?

• Frame

• Filtration Plates

• Diverse (piping and valves)

• Filtration Cloth

What is the Process of Using a Filter Press?

During the fill cycle, the slurry pumps into the filter press and evenly distributes itself. Solids accumulate on the filter cloth, generating a filter cake in the plate's empty volume. The filtrate, or clean water, passes through the ports and is discharged outside of the filter plates.

Filter presses are a type of pressure filtration. The solids build up within the chambers as the filter press feed pump builds pressure, until they are totally full of solids. This is how the cake is made. When the plates are filled, the filter cakes release, and the cycle is over. Many larger filter presses also have quick action automatic plate shifters, which reduce cycle time.

Netsol's filter presses are specifically designed for completely automatic, 24-hour operation in tough environments like mines or chemical manufacturing plants for wastewater treatment.

Filter presses are used in a variety of sectors to separate liquids and solids, including:

- Food and Beverage Processing

- Chemical Manufacturing

- Mining

- Power Generation

- Aggregates

- Asphalt and Cement Production

- Steel Mills

- Municipal Plants

What Is the Purpose Of A Filter Press?

While different types of filter presses work in different ways, they all follow the same principles. A feeding pump is used to pump slurries of water mixed with particles into the press. Pressure from a centrifugal pump or similar equipment drives the slurry through chambers composed of filter plates once within the press. As "filter cakes" of solids pile up on the machine's filters, pollutants are removed from the water.

When the chambers of a filter press are filled, the machine's filtration cycle is finished, and the filter cakes are released. These cakes are simply removed, allowing for high-efficiency water filtration. In filter presses, fast action automatic plate shifters can help speed up cake removal and cycle time. In tougher settings where continuous operation is required, such as mining processes or chemical production plants, a completely autonomous filter press design is required to satisfy the 24-hour demands.

The filter cloth should be specifically developed for your application and the types of solids you are filtering to obtain the maximum performance out of your filter press.

The following can also be tailored to meet your specific requirements:

• Filtration capacity

• Machine design

• Plate size and chamber count

You can also employ extra systems like cloth cleaning systems, drip trays, and cake shields to improve the performance and functionality of your filter press. In the end, each filter press should be built to handle the amount and type of slurry it will be handling. Because filter presses work with pressure, equipment that uses high-pressure technology to enhance pressure is ideal for optimising your filter press system.

Conclusion

Our team of water treatment professionals at Netsol Water Solution can help you combine your dewatering efforts with a thorough water treatment that optimises your systems. We can perform a chemical analysis of your water to determine the best flocculants, coagulants, and pH balancers to utilise to treat it before it goes through mechanical separation. This improves the effectiveness of your clarifiers and filter presses, resulting in a more effective and efficient total water treatment.

Aside from chemical goods, Netsol is a liquid and solid separation expert, with a variety of filter press types and capacities to meet individual application needs for trouble-free, cost-effective dewatering.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.