What Is the Consumer Goods Sector?

The consumer goods sector is a group of stocks and businesses that deal with things that are bought by people and households rather than by producers and industries. These businesses produce goods that are meant to be used directly by customers for their personal enjoyment and usage.

Businesses in this industry are engaged in the manufacture of food, packaged goods, apparel, beverages, cars, and electronics.

The consumer goods sector is diverse with both short and long(er) life cycle products. Consumer items, however, typically have a linear take-make-dispose life cycle. Consumers purchase goods and discard them without giving them any thought. The production of waste and byproducts has an adverse effect on the social, economic, and environmental sectors. Consumer waste generated in India is becoming a crucial issue due to the continuous increase of the population.

In this blog, we are going to discuss in detail the working function of ETP for Consumer goods manufacturing unit

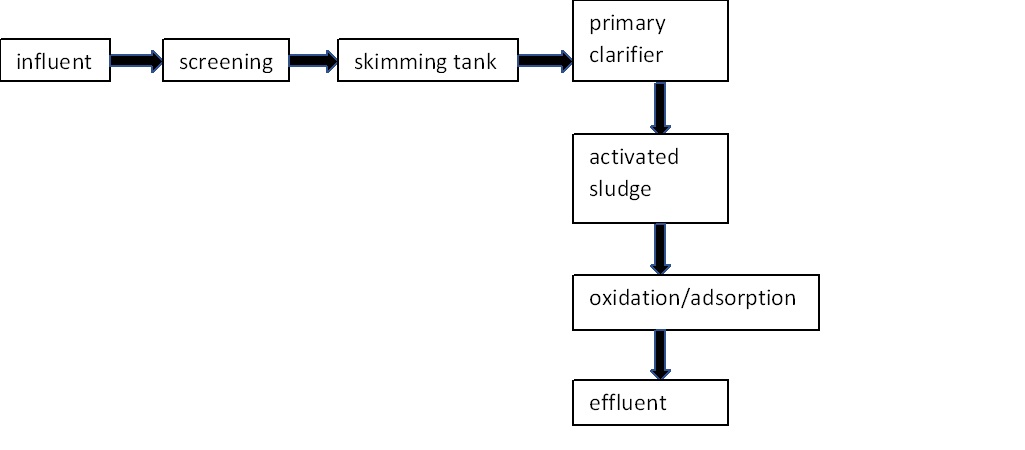

Design an ETP for Consumer goods manufacturing unit with a flow chart

Removal of solids:

Simple sedimentation processes can remove the majority of solids, and the recovered solids are recovered as slurry or sludge. Particular issues arise with very fine particulates and solids with densities that are comparable to water's density. Filtration or ultrafiltration might be needed in such a situation. However, flocculation can be employed with the addition of polyelectrolytes or the usage of alum salts.

Oils and grease removal:

By using skimming equipment, many oils can be collected from open water surfaces. Oil skimmers are thought of as a reliable and affordable means to remove oil, grease, and other hydrocarbons from water, and they occasionally produce the needed level of water cleanliness. The majority of the oil can also be removed by skimming before utilising membrane filters and chemical treatments at later times. Because there is less oil to handle, skimmers will keep chemical costs low and stop filters from prematurely going blind.

Removal of biodegradable organics:

Activated sludge or trickling filters are two common extended traditional wastewater treatment methods that can be used to handle biodegradable organic material of plant or animal origin. If the effluent is overly diluted with washing water or is highly concentrated, such plain blood or milk, issues may occur. Cleaning products, disinfectants, insecticides, or antibiotics may adversely affect the course of treatment.

Treatment of other organics:

Solvents, paints, medicines, insecticides, coking chemicals, and other synthetic organic materials can be exceedingly challenging to handle. Methods of treatment are frequently unique to the substance being treated. Advanced Oxidation Processing, distillation, adsorption, vitrification, incineration, chemical immobilization, or landfill disposal are some of the available techniques. When a substance, like some detergents, may be biologically degraded, a modified method of wastewater treatment can be applied.

Treatment of toxic materials:

Biological processes are typically resistant to toxic pollutants, including many organic substances, metals (such as zinc, silver, cadmium, thallium, etc.), acids, alkalis, and non-metallic elements (such as arsenic or selenium), unless they are very diluted. Changing the pH or using other chemicals to treat the metals can frequently cause them to precipitate out. Many, meanwhile, are resistant to treatment or mitigation, necessitating concentration before being disposed of in a landfill or recycled. Advanced Oxidation Processes can burn dissolved organics inside wastewater.

Process flow diagram of ETP for Consumer goods manufacturing unit

Do you need an advice or assistance on selecting the best water and waste water treatment unit? We have solutions for all your problems!

Let us now your problem, our experts will make sure that it goes away.

For an assistance or related query,

Call on +91-965-060-8473

Or write us at enquiry@netsolwater.com