Why should waste water from laundries treated?

Water is the primary transport medium for removing impurities, adding dyes and finishing compounds, and generating steam. The fundamental worry of the textile industry is the amount of wastewater produced and the high chemical load it contains. Salts, detergents, and organic acids have the greatest environmental impact.

End effluent, which combines numerous streams from diverse processes, has characteristics that are the consequence of a complicated mixture of the following factors:

(a) The fibers employed;

(b) The sorts of articles handled;

(c) The techniques used;

(d) The chemicals and supplementary goods used in the process.

Composition or the substances used in laundering

Soap, soda, detergents, and other chemicals are used in laundry waste to remove stains, oil, grease, and filth from clothing. Laundry waste is generated in the residential zone as a result of hand cleaning, domestic washing machine cleaning, and enormous amounts of effluents produced by commercial washing, including dry-cleaning.

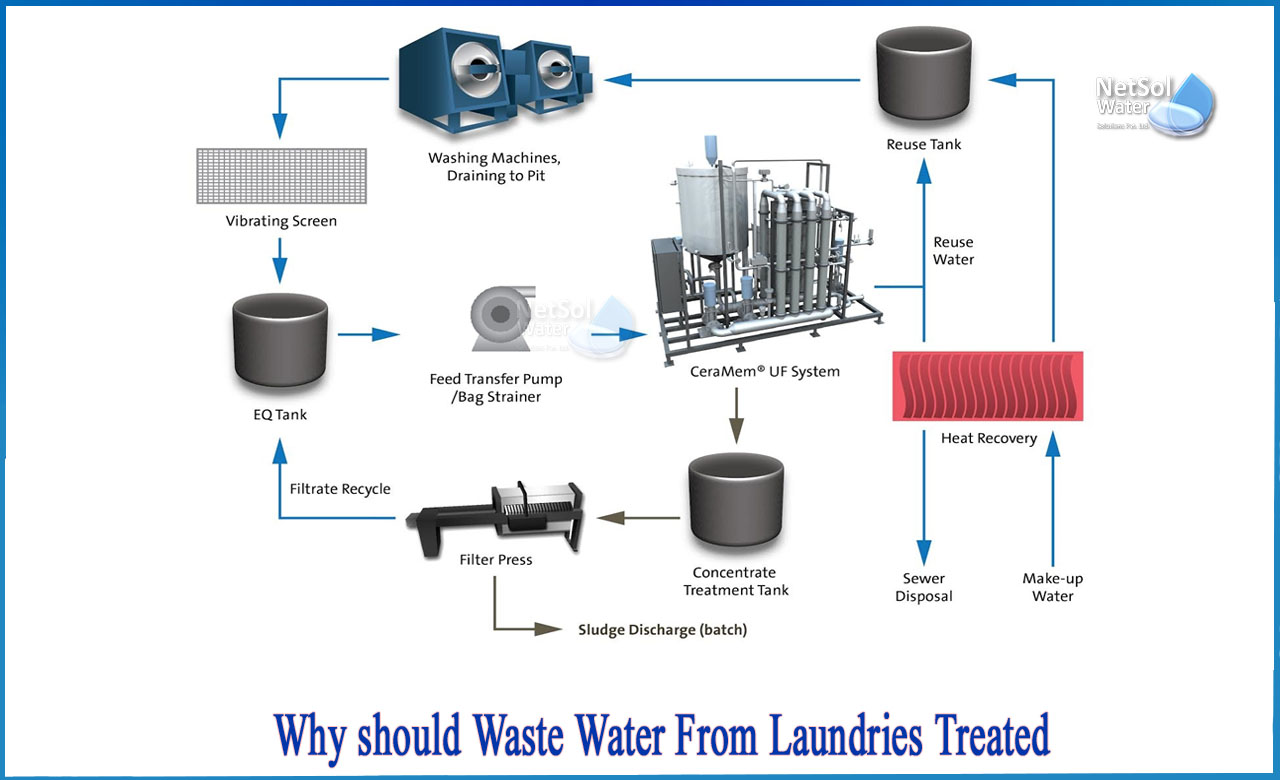

The wastewater treatment process in laundering

Biological, physical, and chemical approaches can all be used to treat effluent. Oxidative ponds, spray irrigation, well disposal, and incineration, among other methods, can be used to treat industrial wastewater.

1. Screening

The initial stage of the process is screening, which is where the influent water enters. This stage involves the employment of an oil skimmer, bar screens, and grit chambers. An oil skimmer is a machine that takes oil and grease from the water's surface. Another piece of equipment that is used as a filter to remove big solid objects such as plastic, paper, and other materials is the bar screen. Grit chambers are another type of mechanical filter that filters tiny solids such as stone and sand.

2. Coagulation and flocculation

It is a chemical reaction. To destabilize the suspended solid particles in the water, lime and aluminumsulfate are added with wastewater. When alum is combined with water, it aids in the faster bonding of solid particles and the formation of bigger solid particles. Lime aids in lowering the pH level. So that it may be easily removed or separated from effluent.

3. Clarifier

A clarifier is a device that sediments solids in a tank at the bottom. This can be accomplished either spontaneously or via the use of mechanical force. In the tank, the velocity of the influent is slowed to speed up the sedimentation of the solid.

There are two types of clarifiers:

Primary and secondary

(a) To remove large solid particles, a primary clarifier is utilized. To eliminate tiny solid particles, secondary clarification is utilized.

(b) The secondary Clarifier tank is larger and has a longer influent detention time.

Finally, sludge is removed from the tank via a pit and a sludge plate.

4. Aeration

The next step in removing carbon dioxide from wastewater is aeration. As small bubbles, oxygen is poured into wastewater. This procedure will aid in the removal of contaminants such as carbon dioxide, hydrogen sulfide, iron, and manganese from the air. The water will be less caustic as a result.

5. Osmosis (reverse osmosis)

Finally, wastewater is filtered via a membrane that allows only water to flow through while blocking waste particles and pollutants.

Thus treating effluents from the laundriesbecomes a major issue before discharging the untreated wastewater directly as it poses a huge danger to our lives as well as aquatic life.

We at Netsol Water design and manufacture Effluents Treatment Plants, Sewage treatment plants, reverse osmosis plants, etc, which performs the task of waste water treatment at great ease.

For more information, contact Netsol Water!

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.