What is effluent?

Effluent is wastewater that does not come from kitchens or toilets, nor does it come from surface water or residential sewage. Any industrial or commercial facility can create and discharge it.

Effluent normally flows directly from the premises into the main sewer system, and it cannot enter a river, reservoir, stream, or lake without first being cleaned and treated.One or more pollutants are commonly found in effluent, including: Food waste; chemicals; detergents; heavy metal rinses; solids; and fats, oils, and greases (FOGs).

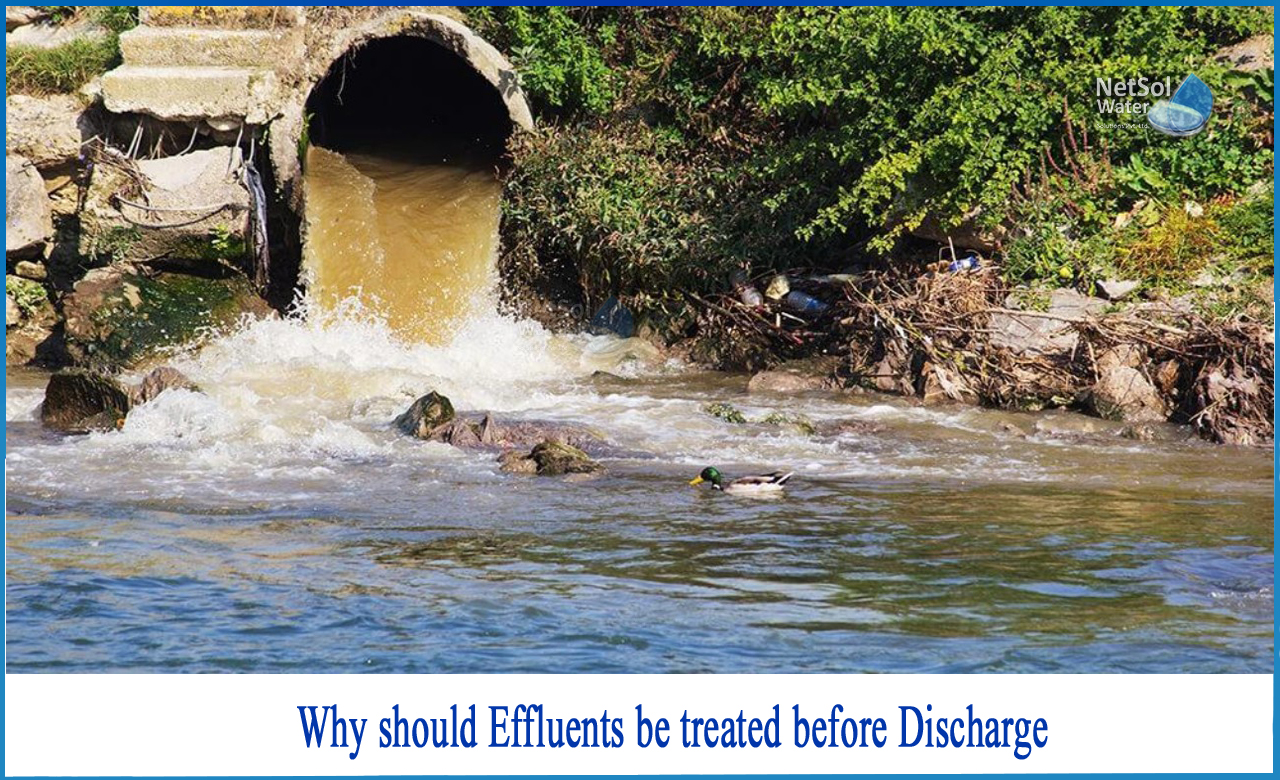

Why should effluents be treated before discharge?

Harmful compounds can be found in wastewater. Suspended sediments, organic and inorganic pollutants, nutrients, saprotrophic and disease-causing bacteria, and other microbes make up this complicated mixture. As a result, untreated sewage discharged into rivers or seas poses a threat to aquatic vegetation and animals. As a result, effluent must be treated before being discharged into a water body, as it can affect human and aquatic life.

How are effluents treated?

Primary, secondary, and tertiary wastewater treatment are the three stages of wastewater treatment. Each cycle improves the purity of the water. Only one or two phases are required in some situations. The amount of treatment required is determined by the water's intended use and the environment into which it will be discharged.

a. Preliminary Treatment: The goal of this step is to physically separate big pollutants. Fabric, paper, polymers, and wood logs, for example. This level/process includes the following:

Screening: The first unit activity in a wastewater treatment plant is screening. The objective of a screen is to eliminate big floating solids by having regular apertures.

Sedimentation: It is a physical water treatment method that removes suspended materials from wastewater using gravity.

Grit Chamber: The wastewater that travels into the grit chamber eliminates the dense inorganic materials that have made their way into the sewers, such as gravel, metal shards, and sand. Grit removal can help prevent pump damage and operating troubles.

Clarifiers: Clarifiers are tanks with mechanical mechanisms for continuously removing sediments that have accumulated due to sedimentation before biological treatment.

b. Primary Treatment: Its goal is to remove floating and settleable elements such as suspended solids and organic matter from the wastewater. Physical and chemical approaches are employed in this therapy. It contains the following items:

Flocculation:Flocculation is a physical process that does not result in the neutralization of charge. It requires forming large aggregates out of destabilized particles so that they may be readily removed from the wastewater.

Coagulation: It is a procedure in which coagulants are introduced to a liquid to help minute solid particles settle quickly into a bigger bulk. It allows for particle removal by sedimentation and filtration.

Neutralization: The major goal of this procedure is to keep the pH between 6 and 9 to fulfil the needs of the various processing units in the ETP.

c. Secondary or Biological Treatment: The goal of this treatment is to remove suspended particles and leftover organics from the effluent from the first treatment. Biological and chemical mechanisms are engaged in this stage.

The Activated Sludge Process: It uses air and a biological floc made up of bacteria to clean industrial wastewater.

Aerated Lagoons: A treatment pond with artificial aeration to improve wastewater biological oxidation.

Trickling Filters: Also known as sprinkling filters, trickling filters are extensively used for the biological treatment of home sewage and industrial wastewater.

Rotating biological contactor:Allowing wastewater to come into touch with a biological medium in order to remove contaminants from the wastewater before it is discharged is known as a rotating biological contactor.

d. Tertiary/advanced/disinfection treatment: The goal of tertiary treatment is to offer a last treatment stage to improve effluent quality before it is reused, recycled, or released into the environment.

Coagulation and sedimentation:After primary and secondary treatment, chemical coagulation and sedimentation are utilized to improve the removal of solids from effluent.

Filtration: To assure high-quality water, the cleared wastewater is first routed to an adjacent filtration facility with massive filter blocks.

Reverse Osmosis: This method involves forcing effluent through a membrane that traps impurities on one side while allowing clean water to pass through on the other.

Technical assistance provided by Netsol_

Netsol Water collaborates with a wide range of international organizations to tackle complicated water and wastewater problems by strategically integrating modern treatment technology with practical solutions.

Think of us when it comes to wastewater management for your organization, adapted to your specific needs! We use a cost-effective method to reuse and recycle water, as well as deal with us for wastewater treatment equipment’s and develop your business while complying with Environmental standards.