How to treat the Effluent from Food Processing Unit?

Effluent treatment is an essential process in food processing units. Food processing units generate a significant amount of wastewater containing organic and inorganic pollutants, which can have harmful effects on the environment if not treated properly.

Now let us have an understanding on how to treat effluent in food processing units and the chemical reactions involved in the process.

Effluent Characteristics:

The effluent generated in food processing units contains high levels of organic matter, suspended solids, fats, oils, and grease (FOG), nutrients, and pathogens. These pollutants can have harmful effects on the environment if discharged into water bodies without proper treatment.

Effluent Treatment Process:

The effluent treatment process in food processing units involves several steps, including pretreatment, primary treatment, secondary treatment, and tertiary treatment.

· Pretreatment:

Pretreatment involves removing large solids and other debris from the effluent. This is done using a bar screen or a grit chamber. The bar screen removes large solids, while the grit chamber removes heavy inorganic solids like sand and gravel.

· Primary Treatment:

Primary treatment involves removing suspended solids and FOG from the effluent. This is done using physical and chemical processes like coagulation and flocculation. Coagulants like alum or ferric chloride are added to the effluent, which react with the suspended solids and FOG to form larger particles called flocs. These flocs are then removed by sedimentation or flotation.

The chemical reaction involved in coagulation can be represented as follows:

M(OH)n + xH2O + yMClz → [M(OH)nClz]y + xHCl

Where:

M is the metal ion,

n is the valency of the metal ion,

z is the charge of the metal chloride, and

x and y are the stoichiometric coefficients.

Flocculation involves gently mixing the effluent to promote the formation of larger flocs. The flocs are then removed by sedimentation or flotation.

· Secondary Treatment:

Secondary treatment involves removing dissolved organic matter and nutrients from the effluent. This is done using biological processes like activated sludge and trickling filter. In the activated sludge process, microorganisms are used to consume the organic matter and nutrients in the effluent. The effluent is mixed with a microbial culture in an aeration tank, where the microorganisms consume the organic matter and nutrients. The effluent is then passed through a clarifier, where the microorganisms and flocs are removed.

In the trickling filter process, the effluent is passed through a bed of rocks or plastic media, which is colonized by microorganisms. The microorganisms consume the organic matter and nutrients in the effluent as it passes through the bed. The effluent is then passed through a clarifier to remove the microorganisms and flocs.

· Tertiary Treatment:

Tertiary treatment involves removing any remaining pollutants from the effluent. This is done using physical and chemical processes like filtration and disinfection. Filtration involves passing the effluent through a bed of sand or other media to remove any remaining suspended solids. Disinfection involves using chemicals like chlorine or ultraviolet light to kill any remaining pathogens in the effluent.

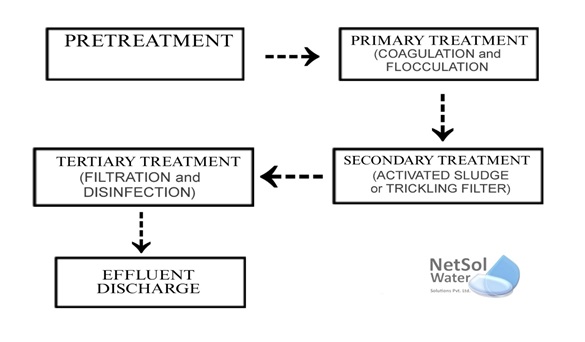

Effluent Treatment Process Flow Diagram:

The effluent treatment process in food processing units can be represented using the following flow diagram shown in Figure 1:

Figure 1 : Flow diagram for treatment process of effluent from food processing unit.

Conclusion:

Effluent treatment is an essential process in food processing units for protecting the environment and public health. The effluent treatment process involves several steps, including pretreatment, primary treatment, secondary treatment, and tertiary treatment.

Leading manufacturer of sewage treatment plants in India.

Netsol Water is the leading manufacturer, supplier, and exporter of a quality selection of water treatment, and wastewater treatment products in India, by using advanced sewage treatment methods.

RO plants, water softeners, ETPs, STPs, DM plants, AMC, O&M, Ultra filtration, UV, Ozonation, ZLD plants, Anoxic tanks, and other goods and services are available from us. We also provide services to businesses in sectors including automotive, pharmaceutical, textile, pulp & paper, beverages, refineries, schools, hospitals, office buildings, and hotels, among others.

Call us at +91 9650608473 or email at enquiry@netsolwater.com for further information.