What is sewage treatment in oxidation ditches?

An oxidation ditch is a customized activated sludge biological treatment technique that removes biodegradable organics by using lengthy solids retention periods (SRTs). Although most oxidation ditches are complete mix systems, they can be changed to approach plug flow conditions.

Applicability of oxidation ditches

The oxidation ditch technique is a proven secondary wastewater treatment method that can be used in any situation where activated sludge treatment (traditional or prolonged aeration) is required. Because the basins can be sized using a suitable SRT to achieve nitrification at the mixed liquor minimum temperature, oxidation ditches can be used in plants that require nitrification. Because it requires more acreage than traditional treatment plants, this method is particularly successful in tiny installations, small settlements, and isolated institutions.

Mechanism of oxidation ditches

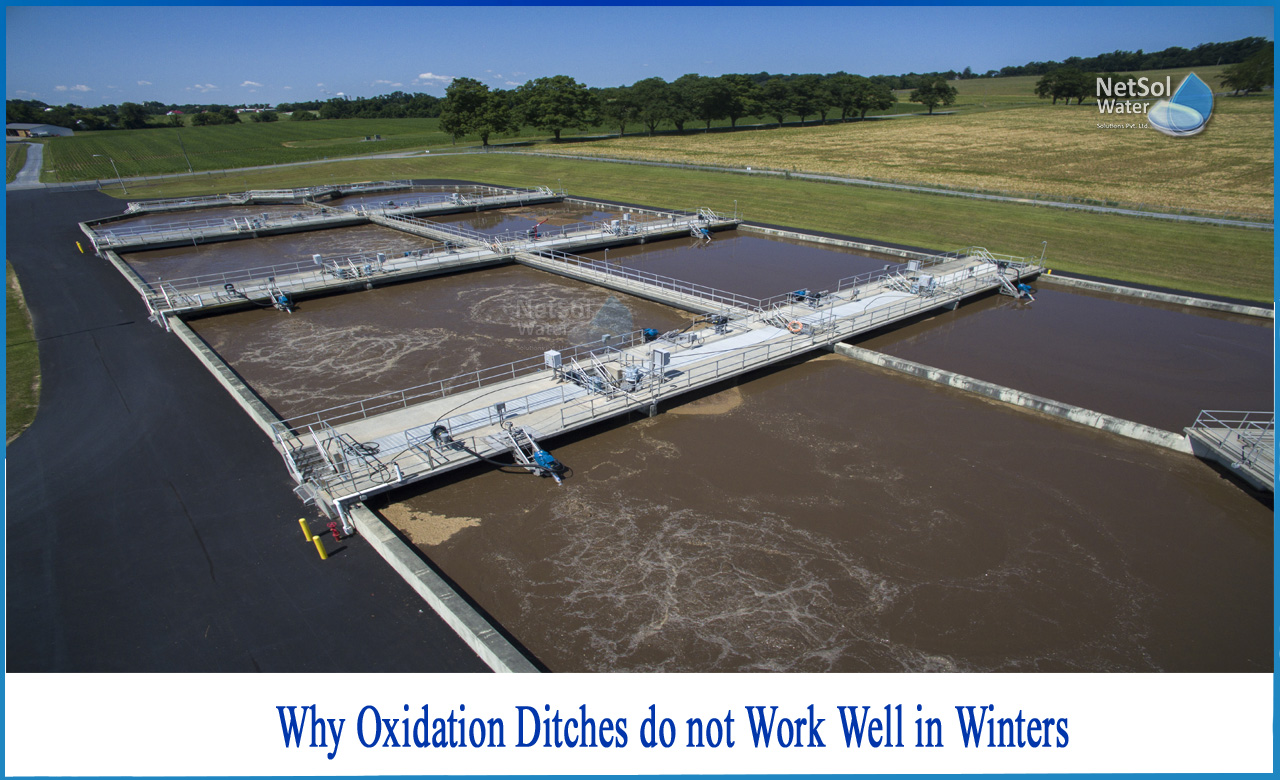

A single or multichannel layout within a ring, oval, or horseshoe-shaped basin is typical for oxidation ditch treatment systems. As a result, "racetrack type" reactors are referred to as oxidation ditches. Aerators positioned horizontally or vertically in the ditch offer circulation, oxygen transmission, and aeration.

The oxidation ditch is usually preceded by preliminary treatment such as bar screens and grit removal. Although primary settling before an oxidation ditch is sometimes used, it is not common in this configuration. Depending on the effluent needs, tertiary filters may be necessary after clarifying. Prior to final discharge, disinfection is essential, and reaeration may be required. The flow to oxidation ditch is aerated. It is mixed with secondary clarifier return sludge.To circulate the mixed liquor, surface aerators such as brush rotors, disc aerators, draught tube aerators, or fine bubble diffusers are utilized. The mixing process introduces oxygen into the mixed liquor, which promotes microbial development, while the motive velocity guarantees that microorganisms come into touch with the incoming wastewater. As the mixed fluid passes down the ditch, the dissolved oxygen (DO) concentration rises significantly but falls as biomass absorbs oxygen. As the mixed liquid circulates around the ditch, solids are kept suspended.

The effluent from the oxidation ditch is normally settled in a separate secondary clarifier. To improve biological phosphorus elimination, an anaerobic tank could be installed before the ditch.

Why oxidation ditches do not work well in winters?

The reason they don't operate well in the winter is that the water cools down, and when the water cools down, the bugs slow down. There is usually not enough loading in the plant for the bugs to survive, and they won't thrive in the cold.

Advantages of oxidation ditches

1: A constant water level and continuous discharge minimizes the weir overflow rate and eliminate the periodic effluent surge typical to other biological processes, such as SBRs,

2: The influence of a shock load or hydraulic surge is reduced by a long hydraulic retention period and thorough mixing.

3: Due to the extended biological activity during the activated sludge process, it produces less sludge than other biological treatment techniques.

4: When compared to alternative biological treatment procedures, energy-efficient operations result in lower energy expenses.

Maintenance and operation

In comparison to other secondary treatment methods, oxidation ditches require comparatively minimal maintenance. In most cases, no chemicals are required, but metal salts can be added to improve phosphorus elimination.

Conclusion

Reinforced concrete is typically used to build oxidation ditches, but other materials such as asphalt, butyl rubber, and clay have also been employed. To avoid erosion, impervious materials are typically employed.

Other secondary treatment techniques have much higher operating and maintenance costs than oxidation ditches. Energy needs are low, operator attention is minimal, and chemical addition is rarely required as compared to other treatment processes.

What can Netsol Water offer?

Netsol Water is a significant water and wastewater treatment firm in India, offering WTP, WWTP, STP, and ETP manufacture, among other services. We have made a mission to save the planet. The company creates equipment’s and is committed to providing practical solutions that help businesses flourish.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.