Designing an ETP Plant for Paneer or Cottage Cheese Manufacturing

Paneer (cottage cheese) is a popular dairy product that is widely consumed in India and other countries. The production of paneer generates a significant amount of wastewater that contains high levels of organic matter, suspended solids, and nutrients. The untreated wastewater can pose a significant environmental threat if discharged into natural water bodies. Therefore, it is essential to design an effluent treatment plant (ETP) for a paneer manufacturing unit to treat the wastewater before discharge.

Here we aim to provide a detailed working function for designing an ETP for a paneer manufacturing unit.

Characterization of Effluent.

The first step in designing an ETP is to characterize the effluent generated from the paneer manufacturing unit. The effluent is typically characterized by parameters such as:

· Chemical oxygen demand (COD),

· Biological oxygen demand (BOD),

· Total suspended solids (TSS), and

· pH.

The following table shows the typical effluent characteristics from a paneer manufacturing unit.

|

Parameter |

Value (mg/L) |

|

COD |

1000-1500 |

|

BOD |

500-800 |

|

TSS |

1000-1500 |

|

pH |

6.5-7.5 |

Selection of Treatment Technologies.

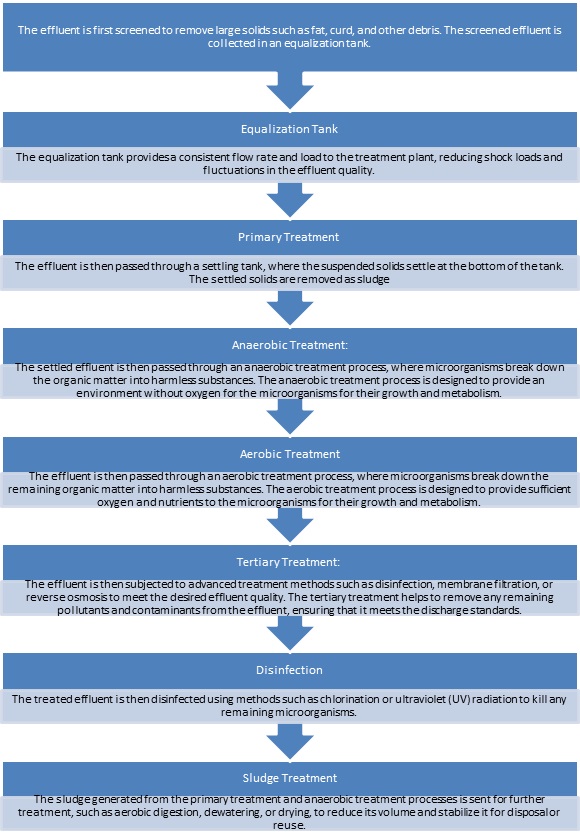

Based on the effluent characteristics, the treatment technologies are selected to remove the pollutants and contaminants. The following treatment technologies are commonly used in the treatment of paneer manufacturing unit effluent whose flow diagram is also shown below:

1. Screening: The effluent is first screened to remove large solids such as fat, curd, and other debris. This step prevents clogging and damage to downstream equipment.

2. Equalization Tank: The effluent is then collected in an equalization tank, which is designed to provide a consistent flow rate and load to the treatment plant. The equalization tank helps to reduce shock loads and fluctuations in the effluent quality.

3. Primary Treatment: The effluent is then passed through a settling tank, where the suspended solids settle at the bottom of the tank. The settled solids are removed as sludge and sent for further treatment.

4. Biological Treatment: The settled effluent is then passed through an anaerobic treatment process, where microorganisms break down the organic matter into harmless substances. The anaerobic treatment process is designed to provide an environment without oxygen for the microorganisms for their growth and metabolism.

5. Secondary Treatment: The effluent is then passed through an aerobic treatment process, where microorganisms break down the remaining organic matter into harmless substances. The aerobic treatment process is designed to provide sufficient oxygen and nutrients to the microorganisms for their growth and metabolism.

6. Tertiary Treatment: The final step is the tertiary treatment, where the effluent is subjected to advanced treatment methods such as disinfection, membrane filtration, or reverse osmosis to meet the desired effluent quality. The tertiary treatment helps to remove any remaining pollutants and contaminants from the effluent, ensuring that it meets the discharge standards.

Summary:

Designing an effluent treatment plant for a paneer manufacturing unit is essential to treat the wastewater before discharge and prevent any environmental threats. The effluent is characterized by parameters such as COD, BOD, TSS, and pH, and the treatment technologies are selected based on these parameters. The treatment technologies include screening, equalization tank, primary treatment, anaerobic treatment, aerobic treatment, tertiary treatment, disinfection, and sludge treatment. The process flow diagram and working function provide a detailed understanding of the treatment processes involved in designing an effluent treatment plant for a paneer manufacturing unit.

Leading manufacturer of sewage treatment plants in India.

Netsol Water is the leading manufacturer, supplier, and exporter of a quality selection of water treatment, and wastewater treatment products in India, by using advanced sewage treatment methods.

RO plants, water softeners, ETPs, STPs, DM plants, AMC, O&M, Ultra filtration, UV, Ozonation, ZLD plants, Anoxic tanks, and other goods and services are available from us. We also provide services to businesses in sectors including automotive, pharmaceutical, textile, pulp & paper, beverages, refineries, schools, hospitals, office buildings, and hotels, among others.

Call us at +91 9650608473 or email at enquiry@netsolwater.com for further information.