Toxicity of effluent components

The toxicity of effluent components after dilution in surface waters is a difficult topic to understand. There is a scarcity of specific data. The lack of exact data stems from the diverse range of aquatic life, the nature of individual components, and their pace of deterioration, whether in suspension or as part of a sediment. Complex and varied effluent components, whose effects on fish, invertebrates, algae, and daphnia might be extremely different, make it impossible to achieve a high degree of specificity. Metals such as chromium, aluminium, and maybe zirconium that may be found in tannery effluents are all classed as having a 'high'/'moderately acute' or 'chronic' harmful effect on organic life and are 'accumulative.'

What is the effect?

An 'acute' effect is one that has a specific effect on fish in less than 96 hours, whereas a 'chronic' effect may require a 21-day test period or even entail whole life cycles, egg counts, and fertility parameters. As a result of this toxicity, ETP is a must have in tannery industries.

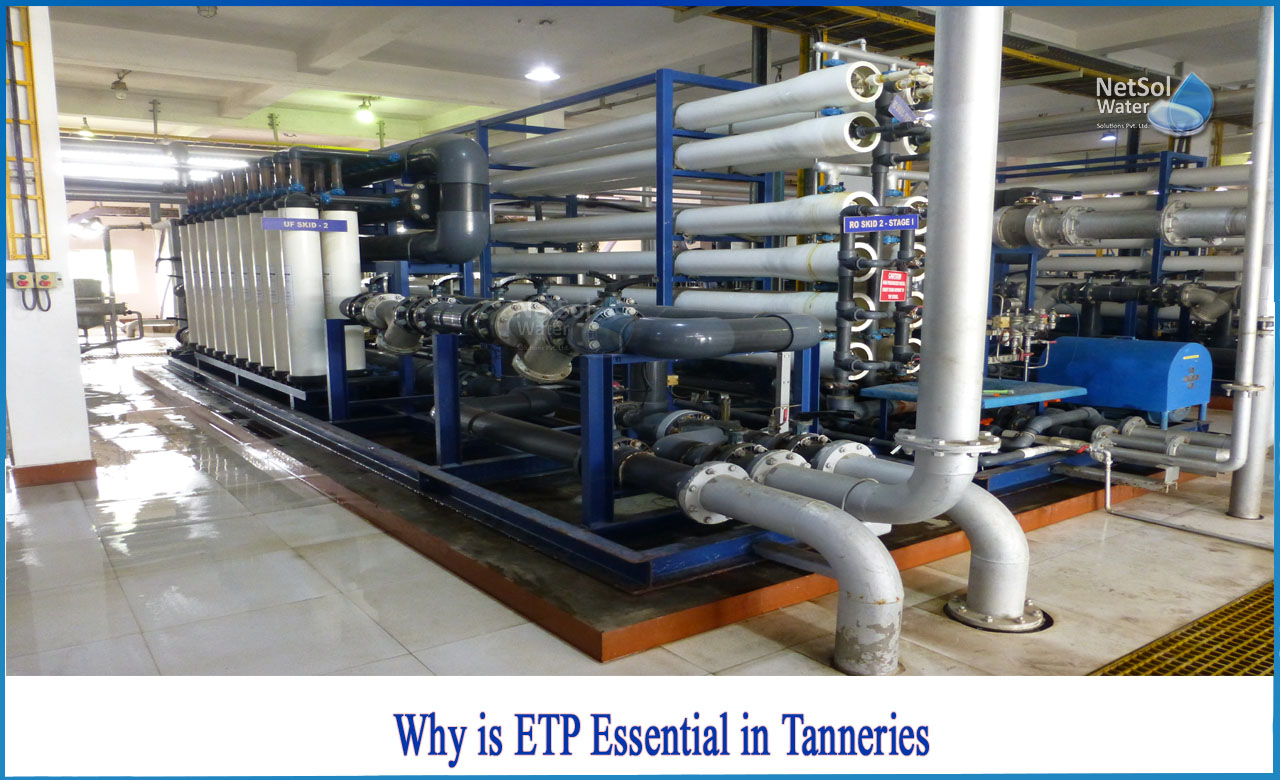

Why is Effluent Treatment Plant essential in tanneries?

The tanning business, one of the world's oldest, is also one of the most polluting, producing a wide range of high-concentration hazardous compounds. The Ministry of Environment and Forests of the Government of India has classified tanneries as highly polluting (Red category) and has placed them under the Central Action Plan. In the tanning process, a large amount of water is used, with 90% of it being expelled as effluent.It's a popular misperception that vegetable tanning is safe for the environment. In actuality, vegetable tanning effluents have a high Chemical Oxygen Demand (COD), which makes treatment challenging.

What are the serious environmental threats?

High chemical levels, such as salinity, organic load (chemical oxygen demand, biochemical oxygen demand), inorganic matter, dissolved, suspended solids, ammonia, total kjeldahl nitrogen (TKN), specific pollutants (sulphide, chromium, chloride, sodium and other salt residues), heavy metals, and others, are recognised as a serious environmental threat. During the chrome tanning process, around 40% of the unused chromium salts are discharged in the final effluents, posing a severe environmental danger. Dermatitis, ulcer nasal septum perforation, and lung cancer are all increased by exposure to chromium, pentachlorophenol, and other harmful chemicals.

What does tannery sludge contains?

In compared to sanitary sludge’s, tannery sludge contains more inorganic matter, more heavy metals, particularly chromium, and more sulphur compounds. The biggest stumbling barrier, however, is the chromium concentration, which varies greatly from nation to country in terms of legislation and practise.

Landfill, land application, composting, anaerobic digestion, thermal treatment, vitrification, pyrolysis, brick making, and other solutions for utilisation and/or safe disposal of tannery sludge have all been proposed, practised, tested, and applied on a pilot and industrial scale, but none have proven satisfactory. Sludge utilization/application does not have a general solution. Each ETP generates sludge with distinct characteristics, and sludge utilisation restrictions vary greatly between areas and countries. As a result, before any ETP is built, a thorough analysis of choices should be conducted and the most appropriate application offered.

What is the effect of odours generated?

Odours associated with wastewater are difficult to quantify because they are caused by a wide range of compounds, and they are a nuisance that is more qualitative than quantitative – sensitive people can detect extremely low concentrations of odoriferous substances in the air (sulphides/other sulphur compounds, ammonia, amines, and so on). Wind direction, land shape, air humidity, ground and air temperature, and other local geographic and climatic conditions all affect it.

The municipality will be responsible for final discharge where tannery effluents are dumped directly into sewers. However, where industrial wastes are discharged directly into surface waterways, the industry may be directly impacted, and investigations may lead to new limitations being set at both the local and national levels.

For design, installation, manufacture and maintenance of STP’s, we at Netsol Water are a call away.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.