What are Fibreglass Reinforced Plastics?

FRP materials are made up of thermosetting polymers and fibreglass. The main element in FRP products is a mixture of resin and glass fibres. The resin is the binder for the glass fibre in the structural laminate and provides environmental and chemical resistance to the product. A resin type is chosen based on the chemical and environmental conditions.

FRP is a popular choice for corrosion resistance and is noted for its mechanical strength. In addition, FRP is lightweight, has excellent temperature resistance, provides thermal insulation, and can be moulded into various designs. FRP products are simple to repair and require little upkeep. Domestic and industrial sectors use FRP materials for effluent treatment plants, sewage treatment plants, fluid storage, and a variety of other specific applications.

What are Packaged Sewage Treatment Plants?

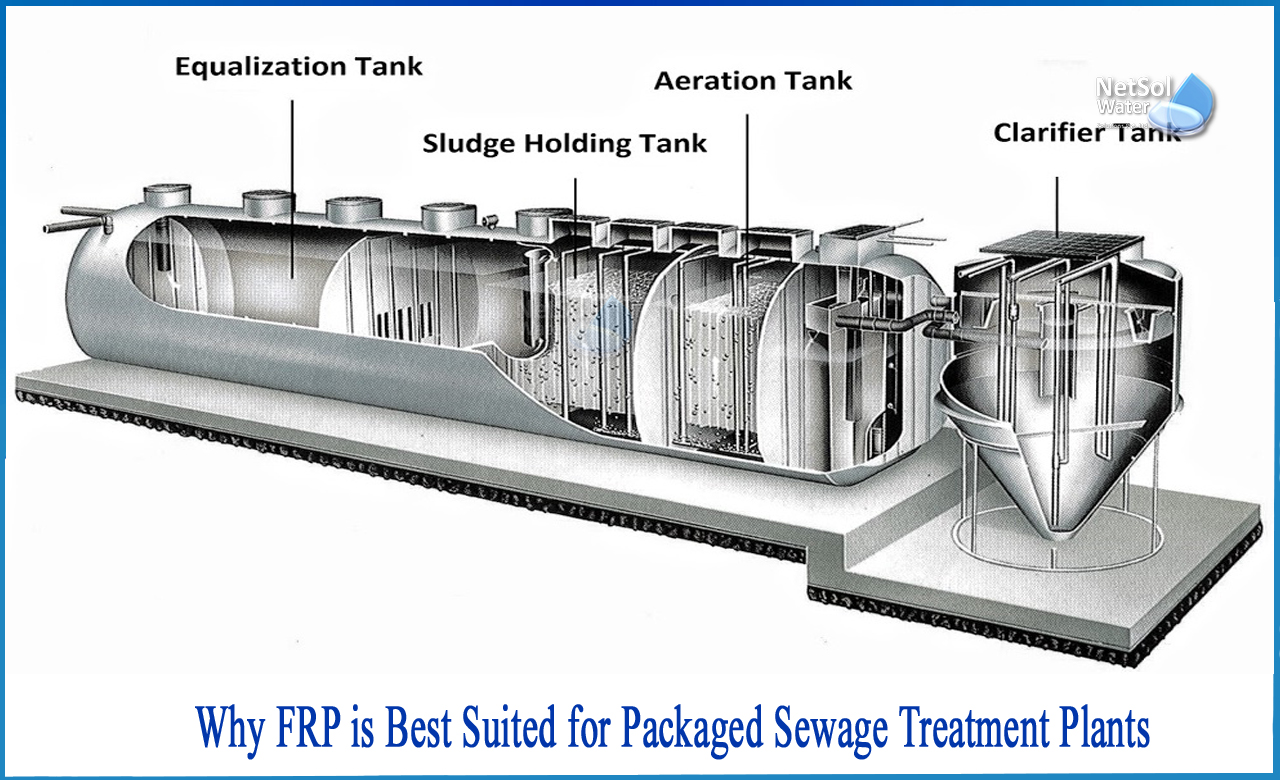

The packaged sewage treatment plant is a cutting-edge and incredibly adaptable technology for the efficient treatment of wastewater, including the removal of nutrients. They can be set up to reduce BOD, suspended particles, ammonical and/or total nitrogen, and phosphorus. The steps are -

First step - The primary goal of this stage of the sewage treatment plant process is to remove coarse particles and other big debris that are commonly found in raw wastewater. Large filtering screens, grit removal, and, in some situations, breaking of large items are common preliminary treatment activities. At the preliminary treatment stage, flow measurement instruments, most often standing-wave flumes, are always included.

Primary step - The major goal of this treatment is to decrease any heavy materials (organic and inorganic) that sinks to the bottom of the tank by sedimentation, while oil, grease, and lighter solids float to the top via skimming.

Secondary step - The primary goal is to treat the effluent after basic treatment in order to remove dissolved and suspended biological materials. Secondary or biological sludge is made up of biological materials extracted during secondary sedimentation and is usually coupled with primary sludge for sludge processing.

Tertiary step - It aids in the removal of those wastewater elements that secondary treatment cannot remove. Sometimes treated wastewater is disinfected.

Why FRP is best suited for packaged sewage treatment plants?

FRP is a composite material made up of fibres and polymers. Because of its cost effectiveness, durability, and extended lifetime when appropriately planned andengineered, it is the finest choice of material for Sewage Treatment Plants (STPs).Because of its long-term durability and cost-effectiveness, its suitability is for a variety of installation options - both underground and above ground.

It requires only a small land area. It has modular pre-constructed systems.It is environmentally friendly as it decreases the carbon dioxide emission in the surrounding environment. There is minimal solids and sludge generation thus it is cost effective. Thus, there are low maintenance requirements with flexible and expandable designs. There is no noise pollution or no odour being released in the environment. The person handling it, has fully – automatic controls.

Conclusion

The FRP Package Sewage Treatment Plant is extremely compact and has a strong design. Furthermore, it uses very little energy, so it may be used without worry about running out of electricity. It is made with the most up-to-date equipment and cutting-edge technology, resulting in an odour-free treatment plant that is simple to use.

In addition, the FRP Package Sewage Treatment Plants is low-maintenance and cost-effective. The biological deterioration in the packaged units is dependent on medium. The specially designed media, which is comprised of UV stabilised and chemically resistant propylene, provides an optimal environment for microorganisms to proliferate and breakdown of incoming organic pollutants. The usage of media also minimises the size of aeration tanks, resulting in a smaller footprint for the sewage treatment plant.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.