Why food industry requires effluent treatment?

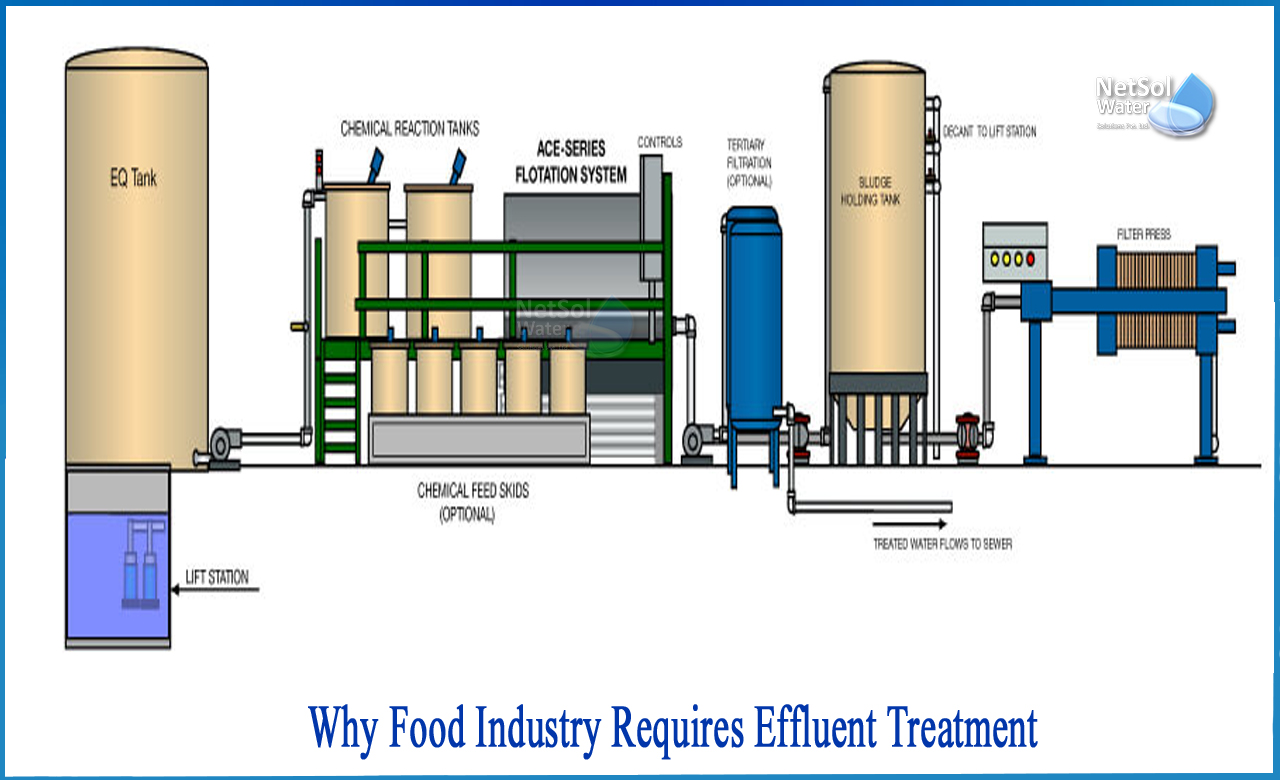

Food Processing Factory produces a variety of food products, some of which are fried foods, which release fats and oils into wastewater streams. Existing processing plants remove most of the products andseparate some of the fats and oils before they are discharged into the sea.

This effluent must be treated before releasing it into water bodies otherwise they will pollute them beyond repair like Yamuna in Delhi, which is now a dead river. Therefore, future treatments may require preliminary treatment and, in some cases, a secondaryor tertiary treatment.

What is Dissolved Air Floatation?

DAF is a process used to remove suspended solids, oils and other contaminants using bubble flotation.

What process is followed?

Air dissolves in water, mixes with the stream of waste, and is released from the solution while in close contact with pollutants. Bubbles form, attach to solids, increase buoyancy, float solids on the surface of the water, where they are mechanically scooped out of the tank. Some of the clean wastewater is recycled, supersaturated with air, mixed with the inflowing wastewater and injected into the DAF separation chamber. Air is injected under pressure into the DAF purified wastewater recycling stream. This recycled stream is then combined and mixed with the inflowing wastewater in the internal contact chamber. The dissolved air then emerges from the solution in the form of very fine bubbles adhering to the impurities. Bubbles and contaminants float to the surface, forming a floating bed of material. This floating bed of material is transferred to the internal funnel by a surface skimmer for further processing. This operation involves a belt filter press or a rotating vacuum drum.

The food industry waste includes Fats, Oils (FOG), Suspended Solids (TSS), Biochemical Oxygen Demand (BOD), Food/Animal Production/Processing Waste, Industrial Waste, Hydrocarbon Oil/Emulsion, etc. DAF is designed to remove many contaminants. With these systems, purification rates of up to 97% or higher can be achieved.

Enhancement of DAF

Chemical pre-treatment often helps improve pollutant removal performance. Traditionally the DAF's design used a recirculation pump in combination with a saturation tank and an air compressor to dissolve the air in water. This type of system is effective, but costly, labour-intensive, destabilizes the equilibrium point, and creates a burp from false, lost, or creeping EQ setting points in saturated vessels.

Effect of chemical pre-treatment

Chemical pre-treatment often improves the efficiency of DAF solids removal. The use of chemical flocculants in DAF depends on the efficiency, application, and cost of the system. Commonly used chemicals include ferric salts of iron such as FeCl2 and FeSO4, or aluminium such as AISO4.Polymers made of organic and inorganic materials (cationic or anionic) are widely used to improve the DAF process.

Effect of pH

The pH of wastewater may need to be adjusted to 4.5-5.5 for iron compounds containing acids such as H2SO4 or bases such as NaOH, and 5.5-6.5 for aluminium compounds. For many applications, DAF sewage should be pH adjusted using a base such as NaOH to ensure that DAF sewage is within the limits.

The attachment of most bubbles to solid particles can be caused by surface energy, while other bubbles are trapped by solid or hydrous oxide flakes as the flakes spread over the water column. Colloidal solids are usually too small to hold particles in the air properly. They must first be solidified by the chemicals such as the aluminium or iron compounds mentioned and then absorbed by the hydrous metal oxide flakes produced by these compounds.

Frequently, a coagulant aid is required in combination with the flocculent to agglomerate the hydrous oxide floc, increase particle size and improve the rate of flotation. Mechanical/chemical emulsions can also be broken down through pH and polymer reactions. DAF float often contains 2% to 10% solids. To reduce sludge content the solids must be dewatered.

Conclusion

DAF is a feasible and easy solution for food industry to treat its effluent and fall in line with the effluent discharge guidelines.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.