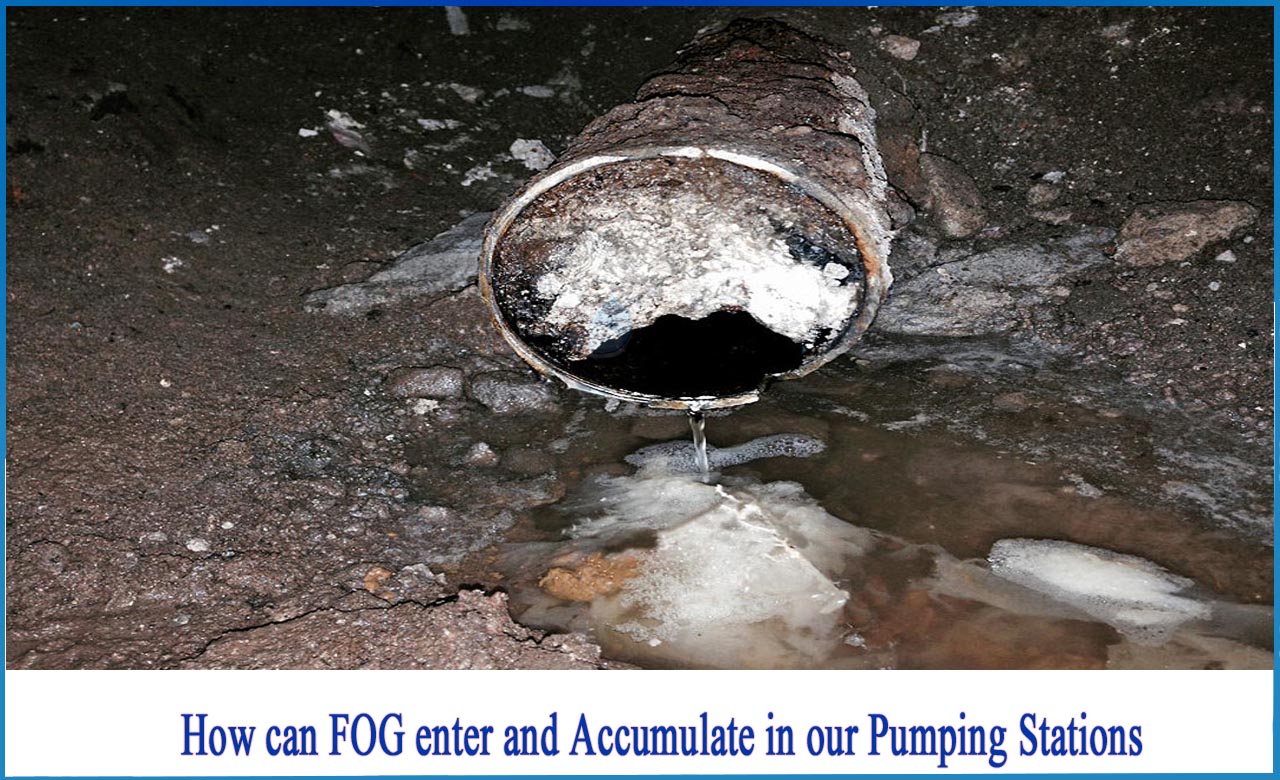

How can FOG enter and accumulate in our pumping stations?

It is critical to remove fat, oil, and grease (FOG) from sewage lines and pumping stations. Fat causes clogging issues in drainage and sewer systems and can be a nuisance. Furthermore, fat accumulation in pipelines and pumping stations generates olfactory nuisance.

Pumping station fat, oil, and grease

A pumping station serves as a natural grease trap, allowing effluent to split into water and fat before being pushed away. Over time, grease can cause damage to the pumps and the floats and sensors that guarantee the pump runs properly causes these pumping stations to become overwhelmed.

The pump station and grease trap should be maintained at the same time; however, a pump station may only require a visit once a year, whilst the grease trap should be emptied once a month. If the pump station continues to function, it will most likely lose efficiency due to grease build-up.It will also add to and contribute to municipal clogs by pumping a lot of grease into the sewage network. If there is too much grease, the pump may fail.

FOG wastewater treatment solutions

FOG is treated in three ways;

The most effective strategy is to prevent FOG from entering the wastewater system at the source. It should then be removed from the sewage system before reaching the wastewater treatment facility. Finally, FOG may be dealt with in the wastewater treatment facility. Traditional approaches include injecting bacteria or enzymes to combat FOG, whilst newer approaches involve activating existing bacteria, causing FOG to break down.

1: Elimination at source

Controlling FOG at the source is the most effective method. To remove FOG, many establishments use a passive grease interceptor device. The brown grease gathered in the trap or GI must be properly disposed of. Grease interceptors must be emptied and cleaned on a regular basis to be effective.

2:Drainage removal

Once FOG has accumulated in the sewage system, it may be required to physically remove it, especially at deposition 'hotspots.' Because of their closeness to residential, commercial, or industrial districts; the features of the sewage pipe, such as its diameter or condition and the characteristics of the sewer network, such as the quantity of inflows, these places will be more prone to FOG clogs.When pipe repairs or modifications to cleaning and maintenance are ineffectual, the only option may be manual collection, which requires a large number of people and has health and safety issues.

3: Elimination at Wastewater Treatment Plant

Traditionally, FOG removal at wastewater treatment plants has involved the use of biological agents to break down and consume grease accumulation. Bioaugmentation is a method that employs bacteria-forming enzymes to disrupt the link between glycerol and fatty acids. These components can subsequently be disposed of by biodegradation, in which bacteria and microorganisms feed on fat, sugar, and starch wastes. Long-term Bioaugmentation often necessitates the constant injection of specialized organisms.

Conclusion

To eliminate and prevent FOG accumulations in sewage networks, Netsol Water employs different products. These are specifically designed to biodegrade fats and oils in sewage pipelines and pumping stations while causing no harm to downstream network components. These solutions also have a prophylactic function, preventing sewage obstructions and unwanted odours such as rotten egg smell. As a consequence, you save money on upkeep and avoid annoyance.

We provide different options for deodorizing sewers in addition to eliminating and preventing clogs in your sewage network. For example, we provide solutions that ensure sewage sulphides are biologically transformed into inert stuff, preventing sewage odours. Please contact us at +91-9650608473 or drop a mail at enquiry@netsolwater.com for further information or to make a purchase.