Why chose Membrane Bioreactors for Municipal WWT?

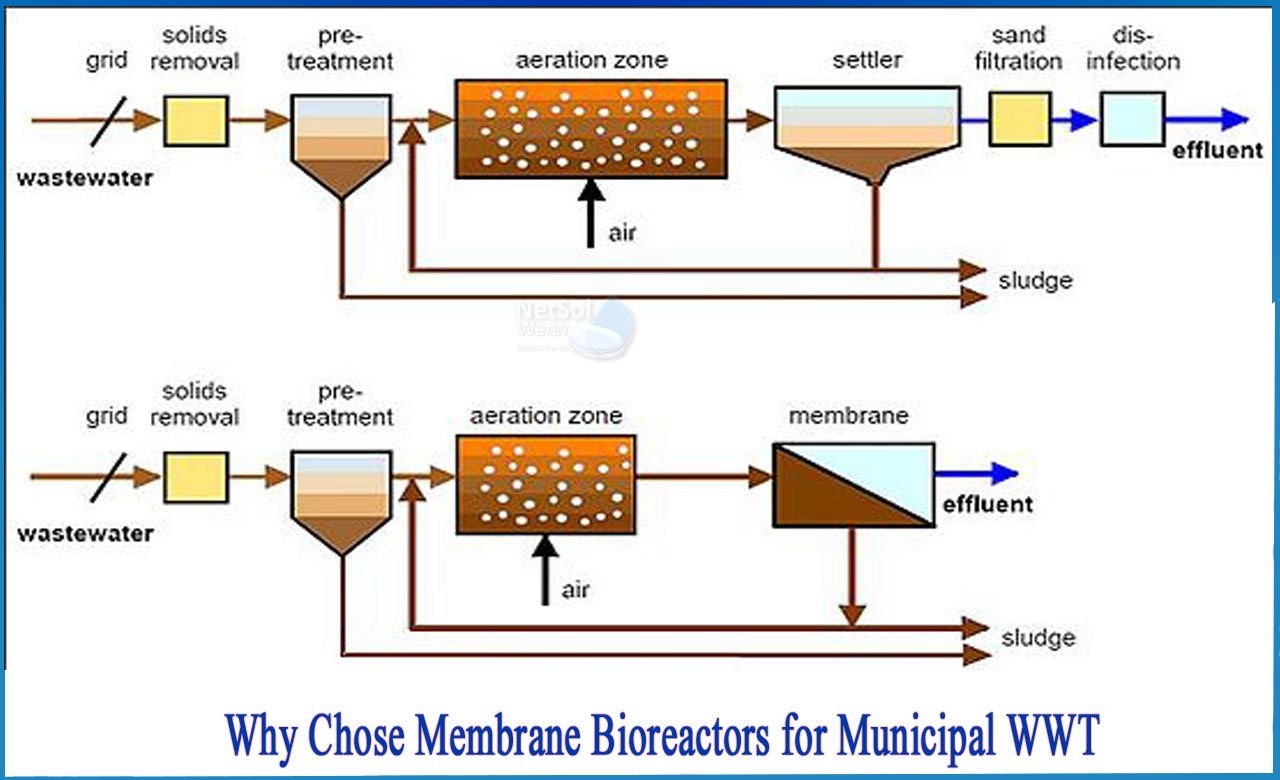

Membrane Bioreactors are a form of secondary wastewater treatment technology that manages to combine membrane filtration with biological treatment. MBRs have customarily been reserved for smaller scale wastewater treatment applications because they are newer and generally more expensive than conventional biological treatment options.

MBR produces high quality effluent systems

MBRs are extremely effective at removing common wastewater stream constituents such as biochemical oxygen demand (BOD), bacteria, total suspended solids (TSS), and even nutrients like nitrogen and phosphorous. One of MBR's most valuable assets is that it gives maximum effluent streams, which enable wastewater treatment plants to safely discharge to surface waterways, meet stringent discharge regulations, and even reuse treated wastewater for other applications.

The appropriateness of MBR technology for water revitalization applications is likely one of the most important factors driving the growth of MBR use at wastewater treatment plants worldwide; in brief, as water recycling efforts have grown in popularity, so have MBRs.

MBR systems are compact

Since, MBRs combine activated sludge, clarification, and media filtration into a single step, they require only about 25-50 percent of the space that a conventional wastewater treatment train would. MBRs are capable of achieving this level of efficiency in part because the bioreactor and filter media elements are designed to maximise surface area. As a result, compared to the conventional activated sludge systems, MBR system must maintain a larger biomass population in a smaller area, a design feature that both saves space and improves biodegradation efficiency. As a result, MBRs may be a good fit for municipalities with limited space.

MBRs for municipal waste water treatment

Since this total flow of sewage is greater than that of industrial effluent, the vast majority of wastewater treatment capacity provided by MBRs worldwide is for municipal wastewater treatment. Similarly, the majority of MBR research, focusing primarily on membrane fouling, is related to municipal wastewater treatment. Municipal plants are also larger in size.

Municipal wastewater is usually treated to meet statutory requirements for discharge to environmental waters, though waste minimization schemes are increasingly being implemented. In roughly descending order of importance, the following contaminants must be removed from municipal wastewaters:

· Phosphate

· Ammonia

· Suspended Solids

· Organic Matter

· Nitrates

· Pathogenic Bacteria

· Micro-pollutants

Pathogenic bacteria must be removed or inactivated before discharge to bathing areas or recycle applications such as irrigation. MBRs disinfect the water while also clarifying it, increasing the effectiveness of a downstream UV irradiation disinfection process.

The onerous nature of micro-pollutants, pollutants that have an impact on the environment even at very low concentrations, has been becoming apparent since the millennium's turn. The future requirement for micro-pollutant removal, particularly trace organic removal, is unknown.

Heavy metals, pesticides and herbicides, fire retardant additives, and pharmaceutical products are among the chemistries of these contaminants.Sewage contains organic and inorganic solids suspended in water, nutrient compounds (nitrogen or phosphorus), and pathogenic bacteria from faeces.

The organic component is mostly resistant to degradation, with a BOD: COD ratio typically in the 0.4:0.5 range. As a result, it is almost always treated biologically, with almost all large municipal wastewater treatment.

For more information, contact Netsol water.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.