How is scaling caused in Water Boilers?

Scaling can be caused by improper water treatment or a failure to apply a treatment plan at all, resulting in irreparable boiler tube damage. Water softening is the process of eliminating the ions in water that cause hardness, most often calcium and magnesium ions. Iron ions also get removed during the softening process.

The best way to soften water is to use a water softening machine that is directly connected to the water supply.

Types of water softening systems

There are several different types of water softening equipment available with Netsol Water Solutions.

The key difference between water softener machines is how the backflush cycles are scheduled. Because recharging the beads with salt too soon wastes salt and water, that is why, it is critical. When you recharge too late, your performance suffers.

There are four different categories of water softeners:

a) Semiautomatic: Only the recharging cycle is started by the operator. When the softener has to be recharged, the operator presses a button, and the device takes over and completes the procedure.

b) Automatic: Automatic softeners have a timer that starts the recharge cycle and each phase of the procedure automatically. The timer is started, and salt is added as needed. This is the most widely used type of softener.

c) Demand-initiated regeneration (DIR): All activities are started and completed automatically in response to the softened water demand. Two softening tanks plus a brine tank are common in DIR systems. The other tank is replenishing while the softening tank is softening.

d) Regeneration off-site (usually rental units): A depleted softening tank is replaced with a recharged tank. Softening tanks that have been used are then replenished at a central place.

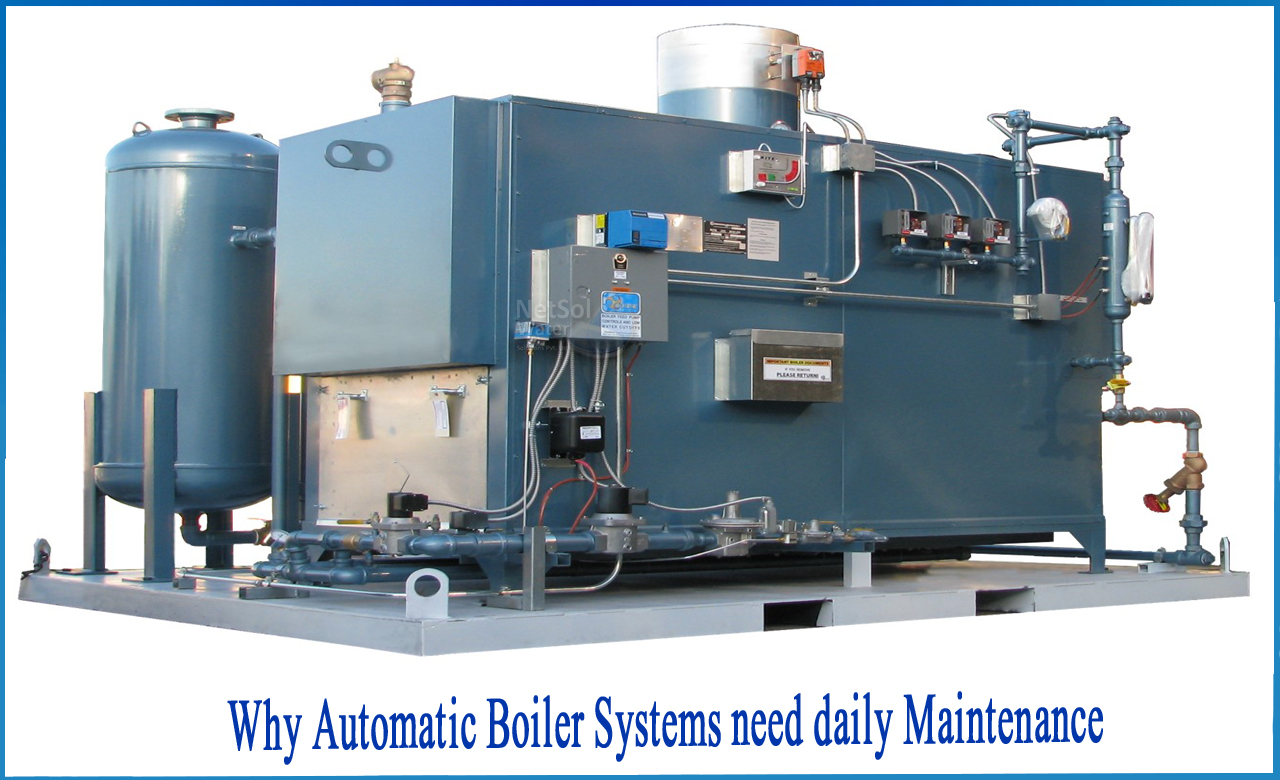

Why automatic boiler systems need daily maintenance?

In the industrial boiler water business, the food industry, and the household water field, fully automatic boiler softening water equipment is widely utilized.

The automatic boiler softening water equipment has a good initial effect, but its performance will deteriorate over time, necessitating large-scale maintenance.

It is vital to guarantee that the input voltage and current are stable in order to avoid harm to the electronic control device.

The salt bridge on the salt valve should be rinsed with clean water on a daily basis as part of the equipment's normal maintenance.

Conclusion

The water softener should be checked and cleaned on a regular basis to ensure that it functions smoothly and without problems. For the greatest results, you should not only choose the best water softener available for home or industry use, but also perform regular water softener maintenance. However, to get the greatest results, hire a professional to clean the water softener on a regular basis.

What can we offer?

Netsol Water, as water and wastewater treatment experts, can help you with water reuse and conservation in your operations, as well as the optimization of existing water production and the design and building of new, energy-efficient, and environmentally friendly water treatment systems like Water Softeners. Our products and solutions can provide the water your plant requires at every stage!