- For Enquiry- 0120-2350053 || +91 9650608473 || +91 9650795306

- enquiry@netsolwater.com

This blog post discusses the treatment used for Electroplating wastewater. We also explains why treating electroplating waste is essential.

Before understanding the electroplating wastewater, its treatment, and use, we must know the meaning of Electroplating.

"Electroplating is the process of coating the surface of a conducting material with metal. It is used to cover a less expensive metal with a more expensive metal. It is also used to cover a corrosive metal with a less corrosive or noncorrosive metal."

The industries that produce the electroplating waste are Electroplating shops, Automotive suppliers (truck, motorcycle, etc.), Jewelry manufacturers, Machine tools manufacturers, Aerospace, Nail and screws manufacturer, Appliances makers, and electronics parts, i.e., Gold plated and silver-plated connectors.

Electroplating wastewater means the wastewater that comes from the surface plating operations. The metal is dipped in an electroplating solution of various types of metals and then rinsed. It originates from washing, rinsing, and batch dumps. What is the treatment for treating Electroplating waste?

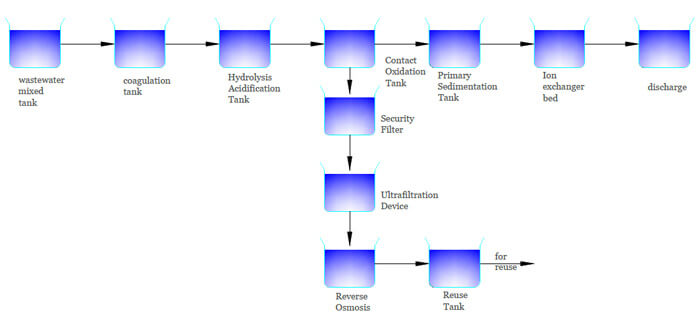

First of all, it is essential to understand that to remove the soluble metals from the wastewater; they must be made insoluble. After that only, the insoluble metal is solidified, flocculated, then clarified by sedimentation. Let us understand the process step by step:

This is the first step in wastewater treatment. This process tries to raise the pH from ~3 to 8.5 with the pH controller by using caustic (ferric chloride). After that, it is tested. Now, testing of the wastewater confirms whether a coagulant is needed or not.

A “pin floc” is developed that indicates the insolubility of the metal. In some applications, plate enhancing chemicals and emulsifiers are present. They may require more sophisticated high-performance coagulants. It will help in breaking down the bonds and allow the metal to precipitate.

The next step after the precipitation and coagulation is flash mixing. In this step, the wastewater with its precipitated pin floc is introduced to the flash mix zone. This is done after adding the polymer flocculants. It helps in maximizing the flocculent dispersion of the coagulated wastewater.

The next step after the flash mix is flocculation. The wastewater goes through the slow mix zone. This is done to agglomerate the pin floc into larger rapid settling particles.

Then comes the next step of Clarifier, inclined plating. In this step, the flocculated wastewater will be introduced into the Clarifier. The settling particles will then land on the inclined plates and will be directed downward into the sludge chamber. The clarified treated water then goes to the top of the Clarifier. It flows down to the sewer. After that, it is further processed for the treatment.

In the clarifier waste sludge handling, the sludge will be slowly removed from the Clarifier and then sent back to the holding sludge tank. The sludge tank then further thickens and accumulates the batch for disposal or processing in a filter press.

In this process, the thickened clarifier sludge will be allowed to accumulate sufficiently to provide an entire batch for the Filter Press. The filter press will pump full of the sludge until it is complete. The filter press will then be emptied of the “cake,” a semi-solid of approximately 20-35 % solids. Sludge cake will be rich in phosphate and should be disposed of as per environmental rules.

Conclusion:

To save our environment from degradation, it should be borne in mind that treating electroplating waste is a must for every industry. It is necessary to be equipped with a wastewater treatment system to protect the environment and its resources. Decreasing the content of heavy metals is very important to eliminate metallic pollution.

If you have any doubts, please feel free to reach us. Contact us to discuss your requirements. We can be reached at +91-9650608473, or feel free to leave your query at enquiry@netsolwater.com.

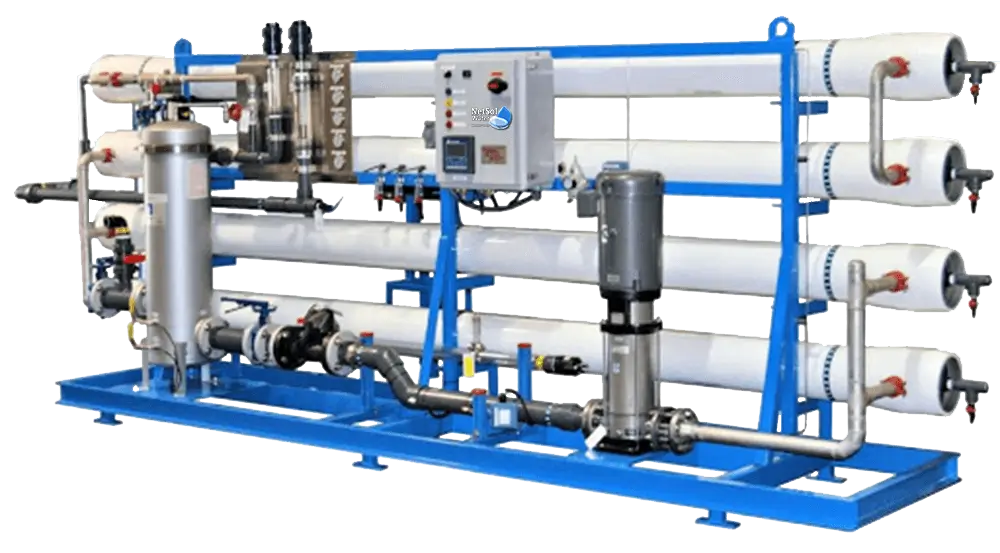

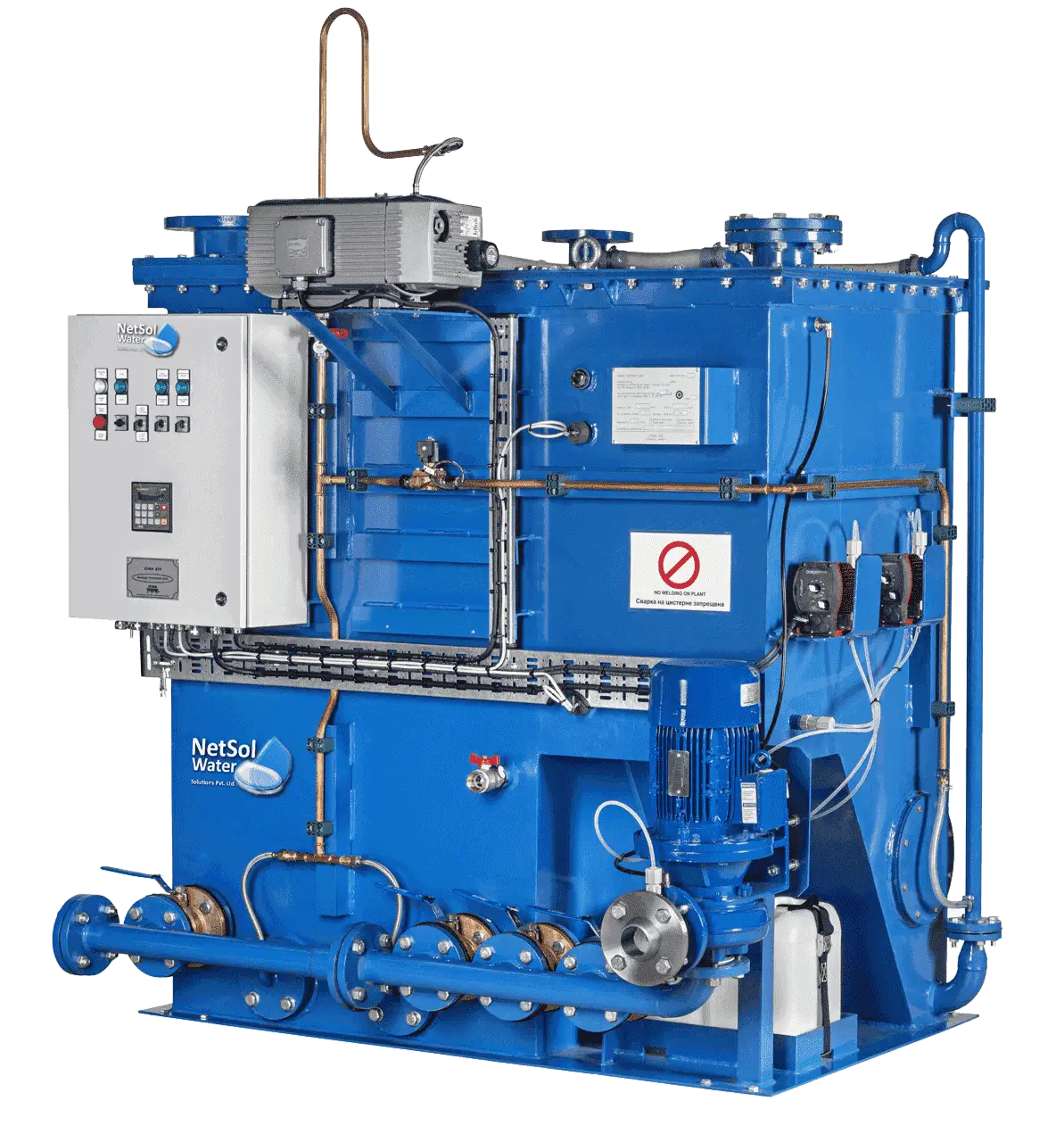

We at Netsol Water have wide range of products like- Industrial RO Plant, Commercial RO Plant, Water Softening Plant and also holding top position as sewage treatment plant manufacturer & effluent treatment plant manufacturers in India.