What is the suspension and sedimentation?

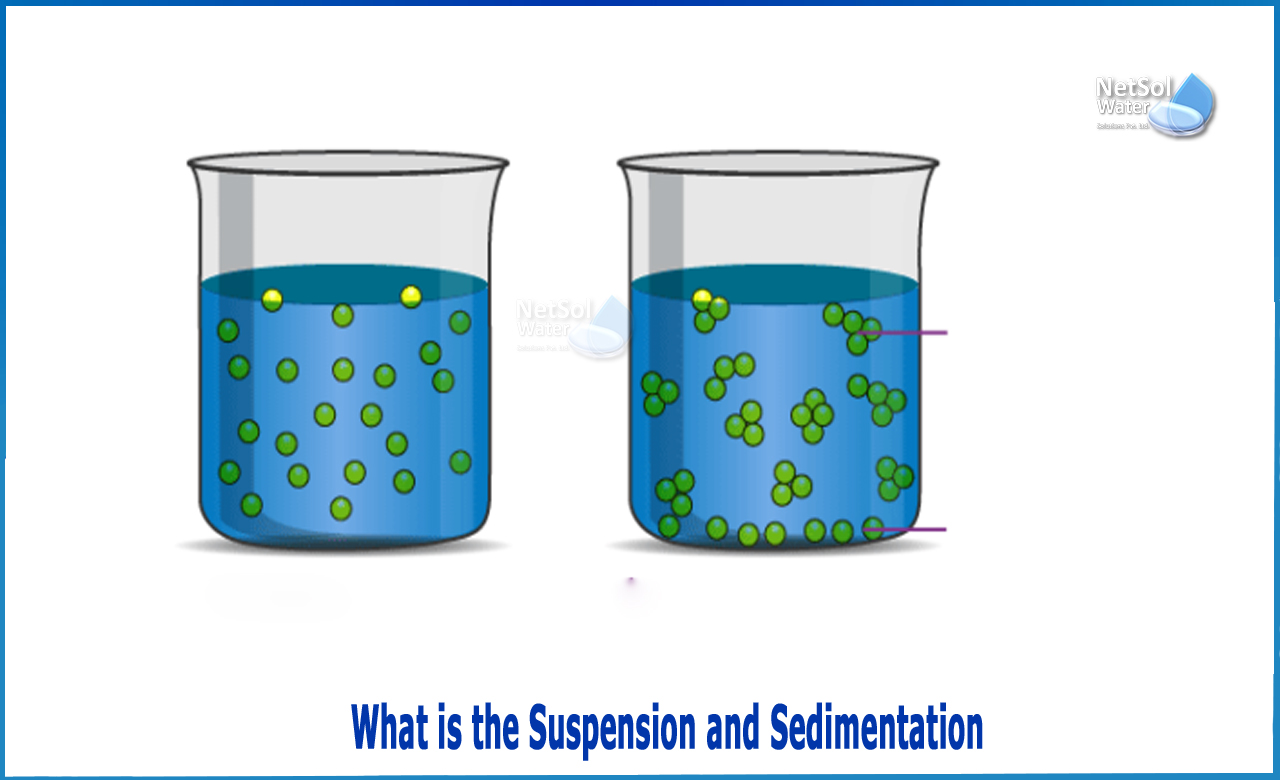

Suspension

A suspension is a heterogeneous combination in which solid particles are distributed throughout the liquid but do not dissolve in it. The separation of a suspension of solid particles into a concentrated slurry and a supernatant liquid in wastewater treatment, is either to concentrate the solid or to clarify the liquid.

Because of their huge size, suspended particles may be removed via sedimentation. It is utilized as one indication of water quality and sewage strength, or wastewater in general. It's a critical design parameter for sewage treatment operations. By removing the majority of the suspended particulates in a water source, the significant water is generally deemed drinkable.

Following this, disinfection is performed to guarantee that any free-floating pathogens or pathogens connected with the little quantity of suspended particles are made useless. Pollutants and pathogens are conveyed on the surface of particles by suspended solids. The bigger the overall surface area per unit mass of particle in grams, the greater the pollution load that is expected to be transported.

Sedimentation

Sedimentation is the process by which particles suspended in water/wastewater settle out of suspension due to gravity.

This approach may be used in water/wastewater treatment to lower the concentration of particles in suspension before due to coagulation, to minimize the quantity of coagulating chemicals required, or after coagulation and, perhaps, flocculation. When sedimentation is used after coagulation, the goal is generally to minimize the concentration of particles in suspension so that following filtering can work as efficiently as possible. The procedure is one of several for use prior to filtration; other choices include dissolved air flotation and various filtration processes. Such solids-liquid separation operations are also referred to as clarifying processes in general.

Sedimentation can be used in a variety of ways, including:

Horizontal movement: The most basic way is to employ rectangular tanks with horizontal flow.The goal is for a substantial proportion of the settling particles to make it to the tank bottom before the water is sucked out at the outlet end. Such horizontal flow tanks are often constructed with a bottom that gradually slopes down to the inflow end of a hopper.

Radial flow tanks are circular in shape, with the water inflow in the centre and a peripheral outflow. Attention must be made to the design of the intake to ensure equal flow distribution throughout the tank. The silt is scraped to a central hopper for disposal.

Inclined plate: Using inclined plates or tubes to provide a wide area with a compact footprint is one way. These are typically made of lightweight materials in modular form that can be readily placed in a concrete or steel tank.

Ballasted floc: A ballasting substance, such as Bentonite or fine sand, can be used to enhance the density of floc particles. In the case of fine sand (80-200 m), it is feasible to recover it for recycling by running the sedimentation tank sludge through hydrocyclones.

The settling rate of floc ballasted with fine sand can be three or more times quicker than that of unballasted floc, and it is often settled in a tank with a counter-current inclined plate system positioned over a hopper where the settled sludge is collected.

What do we offer?

Netsol Water is a significant water and wastewater treatment firm in India, offering WTP, WWTP, STP, ETP, RO Plant manufacture, among other services. We've made it our mission to save the planet. The company creates equipment’s and is committed to providing practical solutions that help businesses flourish.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.