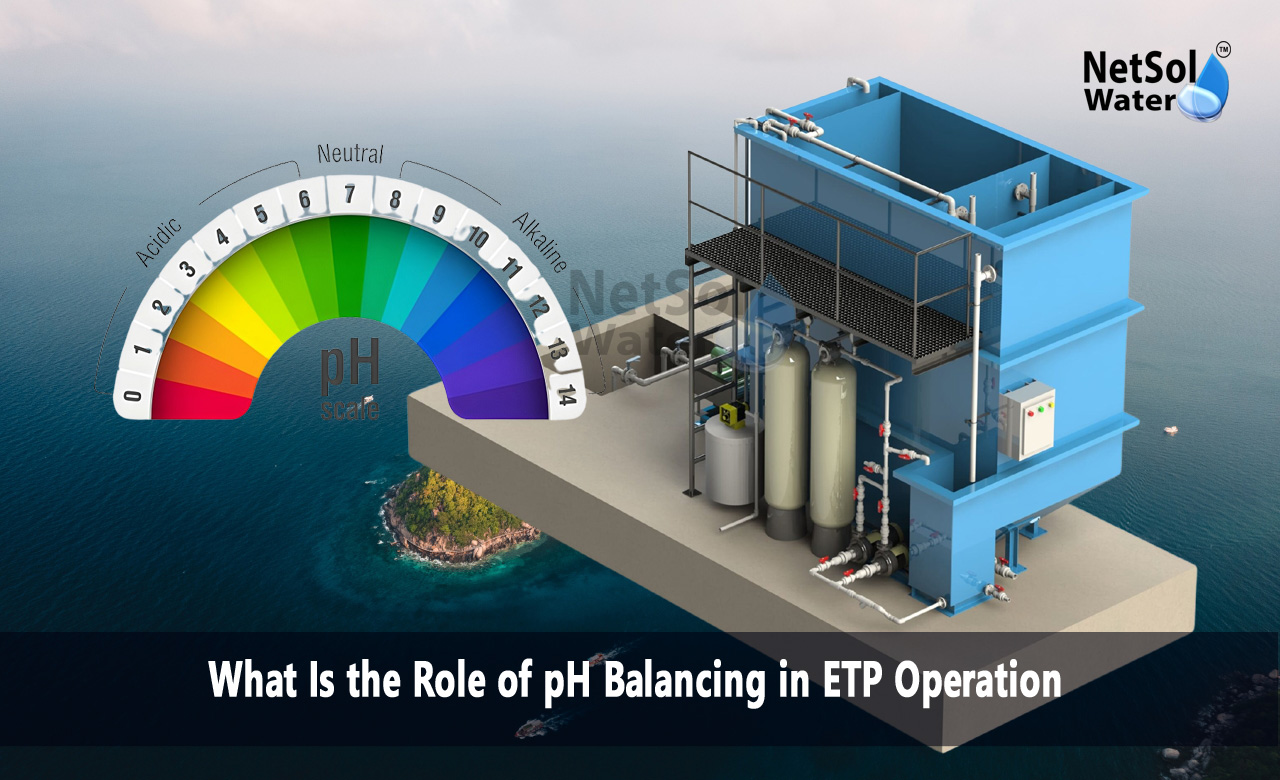

What Is the Role of pH Balancing in ETP Operation?

Effluent water from industries can harm the environment if not treated properly. An effluent treatment plant must operate at a balanced pH level for best results. Netsol Water stands as a leading manufacturer of effluent treatment plants. We design each system to keep pH within exact limits that suit every stage of treatment. This focus helps chemical reactions to remove pollutants. It also supports microbes that break down organic waste. When pH drifts out of range, reactions can slow or stop altogether. Pollutants then remain in the treated water. Equipment may suffer damage over time. Discharge may breach environmental standards. Precise pH control prevents these issues. It protects each process and shields critical assets. It secures compliance with all regulations. This blog will explore the role of pH balancing in ETP operation in depth.

Ensuring Efficient Chemical Reactions

Managing pH forms the first step in many treatment processes. It affects how chemicals interact with pollutants. It decides whether those chemicals can remove or change harmful compounds. Safe pH levels help each dosing step to work as planned.Let us have a look at some ways pH balancing affects chemical processes.

Coagulation and Flocculation

Operators add coagulants to water to gather fine particles into larger flakes. If pH sits too low or too high then coagulant molecules carry the wrong charges. They fail to pull particles together. When pH falls within an ideal range those same coagulants link pollutants into larger clumps. Those clumps settle out in the next tank. Proper pH helps coagulants perform with higher efficiency and lower chemical cost.

Metal Precipitation

Heavy metals dissolve more at one pH than another. By adjusting pH to a set point operators force metals to form solid particles. Those solids float or sink for easy removal. If pH remains off target metals stay dissolved and pass through the plant. Maintaining stable pH thus helps capture those metals reliably. It also cuts chemical waste by avoiding overuse of precipitating agents.

Supporting Microbial Activity

In biological steps microbes digest organic matter in wastewater. Each species of bacteria works best at its own pH. Too far from that range the microbes slow or stop. The result can be poor removal of harmful organics. pH balance keeps the living treatment stage active and strong.Let us have a look at some roles of pH in bio treatment.

Read: Effluent Treatment Plant Manufacturer

Enzyme Function

Microbes rely on enzymes to break complex waste into simple byproducts. Enzymes lose strength when pH drifts too far from neutral levels. That loss slows the breakdown chain. By holding pH near the microbe’s sweet spot we keep enzyme action fast. That in turn speeds up the whole treatment cycle.

Bacterial Growth

Each colony expands only under favorable conditions. pH affects how cells take in nutrients. It affects how they build new tissue. When pH shifts outside the ideal bracket cell walls become weak. Bacteria fail to multiply. By adjusting pH we keep cell walls firm. We thus maintain the biomass needed to treat incoming wastewater.

Protecting Equipment

Effluent plants use many pumps pipes and reactors. Each component can wear when exposed to highly acidic or highly alkaline water. Metals can corrode andscale can clog. Both bring unplanned downtime. pH control guards equipment health.Let us have a look at some ways pH levels protect equipment.

Corrosion Control

Acidic water eats into metal surfaces. It causes rust pits and leaks. Alkaline water can attack certain alloys too. By tuning pH to a safe band we slow corrosion at every stage. We extend the life of pumps valves and pipes. We also avoid costly repairs or replacements.

Scale Prevention

Hardness and other minerals form deposits when pH climbs too high. Those deposits build into thick scale on reactor walls and membranes. Scale cuts flow and reduces heat transfer. By keeping pH in check we prevent scale from forming. We maintain steady flow rates and avoid extra cleaning steps.

Meeting Discharge Standards

Regulators set strict pH limits for all treated effluent. Plants must not release water outside that bracket. Exceeding those limits brings fines and legal risks. pH balance helps operators meet those rules without risk.Let us have a look at some regulatory needs related to pH.

Effluent Criteria

Most standards demand that treated water falls between pH 6 and pH 9. That range avoids harm to rivers and lakes. By monitoring pH online operators can act fast if levels shift. They add acid or alkali as needed. They thus keep out of breach of the permit at all times.

Monitoring and Reporting

Plants log pH readings around the clock. They collect data to prove compliance. Automating pH control cuts human error. It also creates a digital record of every day’s performance. These logs feed into regular reports sent to regulators. They show that the plant meets all limits.

Conclusion

In every effluent treatment plant the role of pH balancing in ETP operation shapes each process. It drives chemical dosing. It fuels biological breakdown. It shields equipment from damage. It ensures safe discharge to the environment. As a leading effluent treatment plant manufacturer, Netsol Water brings deep expertise in pH control systems. We deliver reliable sensors mixers and dosing skids sized to each plant. We also offer ongoing support and service contracts. If you want to learn more about the role of pH balancing in ETP operation get in touch today. Request a consultation and let our experts guide you to more efficient treatment.

Contact Netsol Water at:

Phone: +91-9650608473, Email: enquiry@netsolwater.com