Sludge Dewatering

Sludge dewatering is the process of separating sludge into liquid and solid components in order to reduce waste. It is crucial to note that dewatering does not treat the sludge or liquid; rather, it separates the solid and liquid components so that the distinct phases may be handled more easily and cost-effectively for eventual disposal. Both the solid and liquid components of dewatered sludge may include contaminants that must be treated individually.

The goal of sludge dewatering is to reduce the weight and volume of sludge so that disposal costs, including transportation, are maintained to a minimum. The principal method of volume decrease is water removal. Dewatering is required before sludge waste may be processed or disposed of in the most cost-effective manner.

What is the purpose of a centrifuge?

A centrifuge uses centrifugal force to separate materials based on their densities, similar to how a spinning top stays upright. Centrifuges are employed in a variety of applications, from pharmaceutical manufacture to extracting cream from milk, as well as a variety of other industrial applications such as sludge dewatering.

When using a centrifuge to separate materials, those with higher densities will be moved further away from the axis than those with lower densities. When using whole milk, the cream will "spin" out of the milk, resulting in a separation of materials of different densities.Centrifuges come in a variety of shapes and sizes, and they're used for a variety of purposes.

What is the process of Centrifugation in Sludge Management?

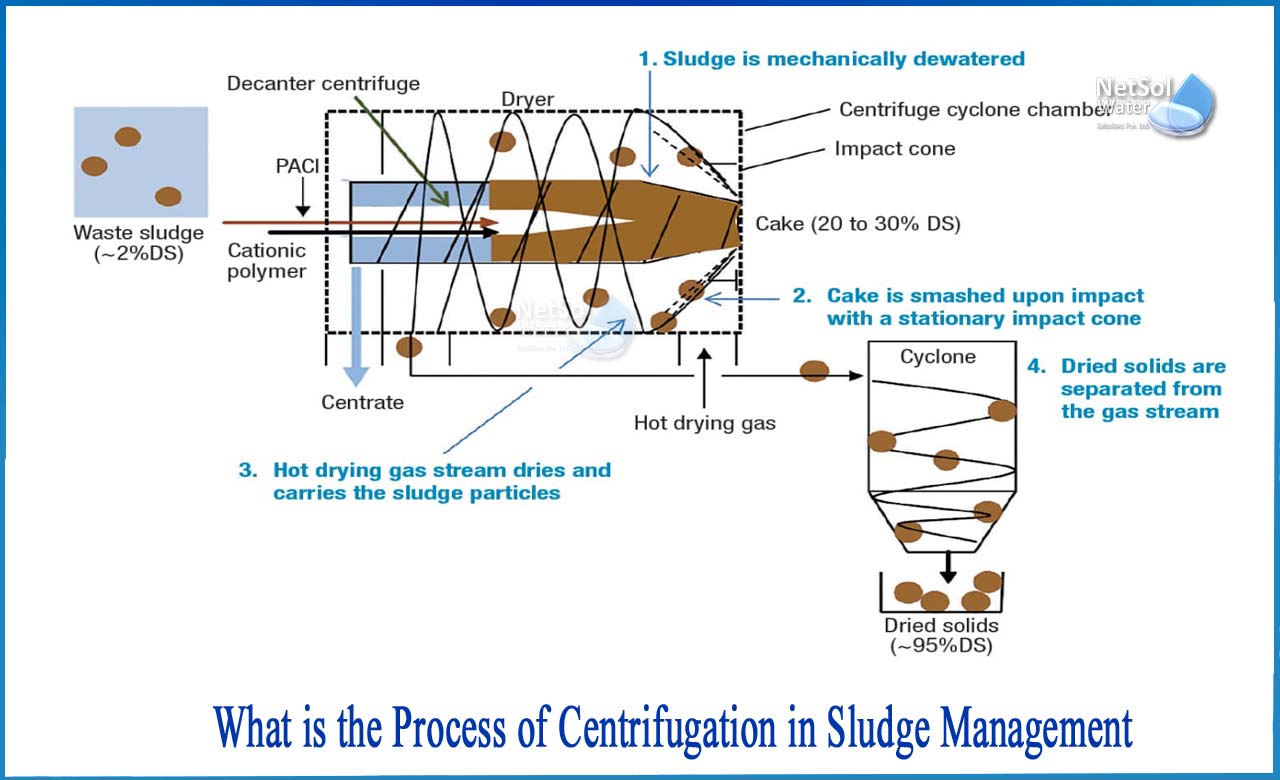

Centrifugal thickening and dewatering of sewage sludge is a high-speed technique that separates wastewater solids from liquid using the force of rapid rotation of a cylindrical bowl to generate a non-liquid material known as "cake." Dewatering wastewater solids minimises residuals, improves operation, and lowers expenses for storage, processing, transfer, end use, or disposal, among other advantages. Since the 1930s, centrifuges have been utilised in wastewater treatment.

What is centrifugal sludge dewatering and how does it work?

Centrifugation is used to thicken and dewater sewage sludge, with dewatered sludge having a higher concentration of dry solids (DS).The centrifuge technology employed in each case is nearly identical. The rotation speed used, the throughput, and the operational variances between the two roles are the most significant operational differences.

Nature of the resulting concentrated solid products

Because more water must be eliminated to obtain higher solids concentrations, dewatering requires more energy than thickening. The dewatered product takes the shape of a cake, a deformable semi-solid that forms lumps rather than a free-flowing fluid, with a dry solids (DS) percentage as high as 50%. As a result, it can only be transported by conveyor belt, whereas a thickened product keeps the feed's fluid qualities and can be pumped.

The solid bowl centrifuge, also known as a decanter or a decanting centrifuge, is the most frequent form of centrifuge used for dewatering applications, much as it is for thickening. The quality of the feed sludge and the dosing parameters affect its dewatering and solids recovery.

Centrifuge Advantages

• Costs of maintenance and operation are reduced

• Processing Time Saved

• Quick commissioning and setup

• A wide range of sizes

• Increased capacity for throughput

• Maintenance and repairs are simple due to the ease with which items may be removed and replaced

• Centrifuges are simple to maintain

• While centrifuges require an experienced operator to operate them, when operations are stable, they only require minimal operator attention

• Aerosols, infections, hydrogen sulphide, and other odours are minimised in centrifuges

• Costs of transportation and disposal are lower

Conclusion

Sludge dewatering can be accomplished using a variety of processes. However, deciding which technology is best for your business can be difficult. The possibilities are infinite, with centrifuges, filter presses, and geomembranes among them.

Netsol Water is a significant water and wastewater treatment firm in India, offering WTP, WWTP, STP, and ETP manufacture, among other services. We've made it our mission to save the planet. The company creates equipment’s and is committed to providing practical solutions that help businesses flourish.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.