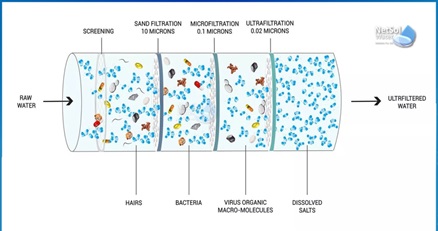

A hollow fibre or sheet membrane is used in the water treatment procedure known as ultrafiltration, to mechanically filter water containing very minute particulates. This UF membrane technology is used in drinking water systems, to filter particles which are as small as 0.025 microns. Ultrafiltration also serves as a pre-treatment for RO and ion exchange processes.

Let’s study the working of ultrafiltration process, the pore size of an ultrafiltration membrane, as well as the uses of ultrafiltration plants in this article.

What is the process of an ultrafiltration system and its work?

Ultrafiltration system functions essentially the same as other water filtration methods.

1: Water passes through a sediment filter, where the porosity of the filter allows it to catch particulate matter.

2: A carbon filter is also added to the system to get rid of undesirable taste and odour.

3: Suspended particles are removed using the traditional filter (cartridge filter or media filter) by trapping them in the filter media.

4: The membrane serves as a barrier to molecules, colloids, and ions rather than collecting ions.

The liquid stream runs tangentially along the membrane surface. Two streams are therefore produced.

Permeate is the term for the stream that is in touch with the membrane. The quality of the feed, the properties of the membrane, and the operating circumstances, are only a few of the factors that influence penetration rate.

Concentrate stream is the name of the other liquid stream.

Since, the filters serve as a storage area for solids, they must be cleaned frequently to keep up their high levels of efficiency. These must be replaced after a period of wear and tear. Also, ultrafiltration does not involve the use of a standard pre-filter. All suspended and emulsified particles must be filtered through the membrane filter.

What is the pore size of an ultrafiltration membrane?

The pore size of the hollow fibre ultrafiltration membrane used in the filtration process, ranges from 0.01 to 0.1 micron, which is thousands times smaller than a human hair. When water enters, the pore size determines which particles are held on the membrane's surface, and which flow through to produce potable water. Beneficial minerals and water that are smaller than the pore size pass through.

Which factors influence the Ultrafiltration Water System's performance?

1: Flow Velocity

The permeate rate is inversely proportional to the flow velocity over the membrane's surface. This metric becomes even more important when dealing with high viscosity liquids like suspensions and emulsions. More energy is needed for pumping as the flow increases.

So, it's crucial that the velocity doesn't exceed the ideal range because doing so reduces efficiency. By figuring out the appropriate ratio between pump energy and permeate rate, it can be accomplished.

2: Pressure

The permeate rate is also impacted by pressure applied to the membrane surface. The operating pressure must be kept low in capillary-based ultrafiltration membrane modules, due to structural constraints. Compaction and fouling are also brought on by extremely high pressure.

3: Temperature

The performance of an ultrafiltration system is significantly influenced by temperature. The penetrate rate often rises as the temperature rises.

What kinds of pollutants does the Ultrafiltration (UF) membrane eliminate?

The UF membrane has very less effect on chemicals or TDS, but it is very good in removing:

· sediment,

· chlorine,

· taste,

· odour,

· benzene,

· algae,

· copper,

· lead,

· mercury,

· endotoxins,

· plastics,

· proteins,

· silica,

· silt,

· smog,

· virus, etc.

Benefits and features of ultrafiltration plants

· No requirement for chemicals (coagulants, flocculants, disinfectants, pH adjustment)

· Media depth filtration as opposed to size-exclusion filtration

· Consistent quality of treated water in terms of the particle removal and microorganism removal

· Compactness of the process and plant

· Easy automation

· Eco-friendly

· Systems with modules help with easy installation

· Efficient system of separation

· Plant uses less energy

· Excellent grade of treated water

· Long-lasting membrane with low fouling conditions

· Control panel with a manual or PLC.

· Advanced controlling and monitoring system installed

What are the uses and applications of Ultrafiltration Plants?

· Metallic industries

· Ion exchange and RO pre-treatment

· Post Ion Exchange treatment

· Valuable pollutants are recovered

· Wastewater reuse, etc.

Maintenance of ultrafiltration systems

Very tiny membrane filters are used in ultrafiltration systems. They must be thoroughly cleaned. The cleaning process will be impacted by whether a UF system is being used to remove organic, inorganic, or both the types of impurities.

Procedure of membrane cleaning in ultrafiltration plants

1: To remove organic contaminants, the recommended cleaning process for tubular membranes calls for using low foam, medium-alkaline detergent at 0.6 % to 1 % for a maximum of 40 to 60 minutes.

2: The most effective method for eliminating inorganic contaminants, is the use of citric acid at a maximum concentration of 3.0 %. The acid should circulate for one to three hours.

3: Oxalic, sulphuric, nitric, and hydrochloric acids can all be used to clean membranes.

Leading supplier of ultrafiltration plants in India

Netsol Water is a well-known brand providing a broad range of Ultrafiltration water treatment equipment’s. We support dependable, high-quality systems that offer clients a strong “Return on Investment”.

When you rely on us for high-quality systems, you can be sure that the results are the best. Call us at +91 9650608473 or email at enquiry@netsolwater.com for further information.