Overview

Depending on the architecture of the wastewater treatment plants, the Grit Chamber comes after the Screen or the Equalization and Neutralization tank.

Grit Chambers, sometimes called as grit channels, are sedimentation basins found after the fine screens and, in most instances, before the principal sedimentation tank. Inorganic grit having a diameter of 0.15 to 0.20 mm or bigger, such as sand, gravel, and other mineral particles, is removed by the grit chamber. Rags, coffee grounds, vegetable cuttings, ash clinker, wood pieces, and tea leaves are examples of non-putrescible organic matter, as well as microscopic mineral particles that may settle.

Although certain grit components, such as coffee grounds, are organic, they are essentially non-biodegradable during the grit collecting and disposal processes.Grit removal channels are designed to remove all particles with a specific gravity of 2.65 or higher, a diameter of 0.20 mm or more, and a settling velocity of about 0.02 m/s (at 10°C); however, some grit removal channels are designed to remove particles larger than 0.15 mm with a settling velocity of about 0.015 m/s (at 10°C).

As a result, the grit chamber must be built to scour the lighter organic particles while ignoring the larger grit particles.

Objectives of grit chamber

1: Pumps and other equipment’s will be protected.

2: To avoid treatment overload.

3: To minimize the frequency of sedimentation tank cleaning.

4: To prevent pipe blockage.

Girt Chamber classification: Classification of Grit chamber

1; Horizontal type flow

2; Girt Chamber with Aeration

3; Chamber with a Vortex Girt

Here, we will discuss about the Vortex flow Grit Chamber!

What is Vortex flow grit chamber?

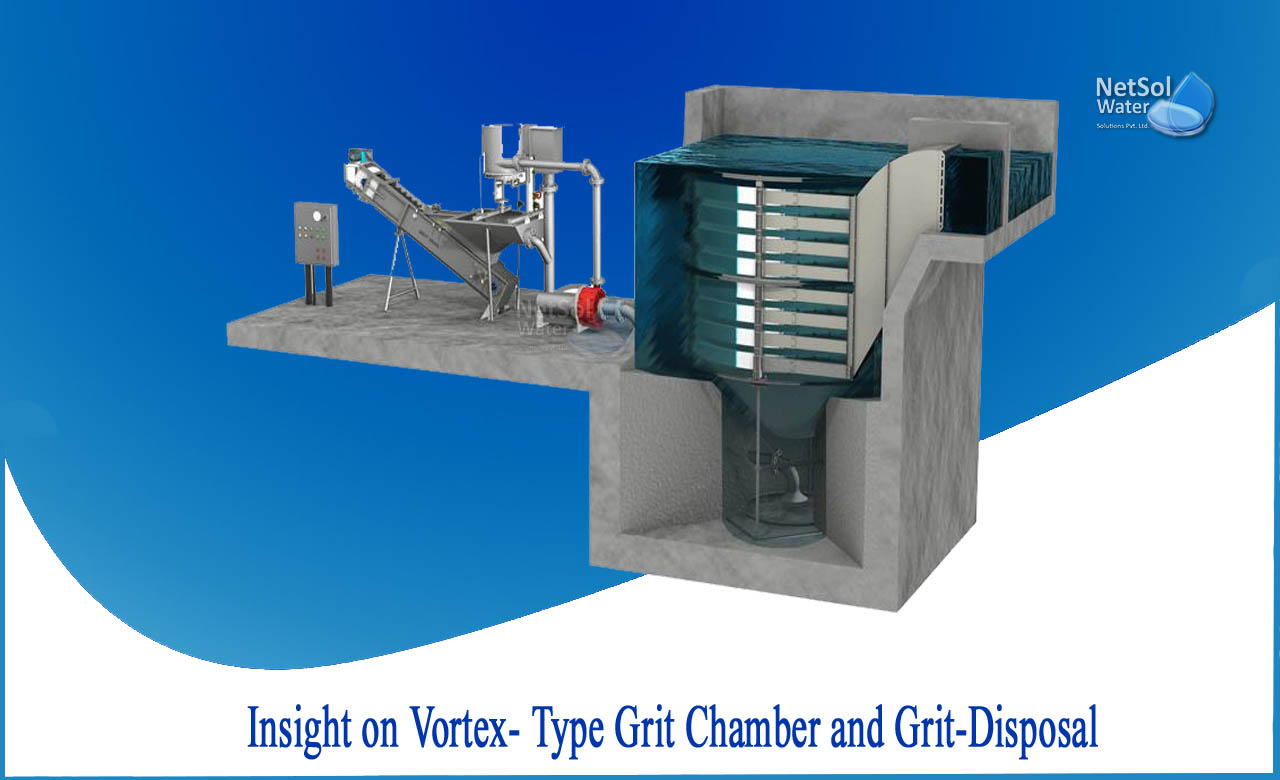

These sorts of grit chambers are employed in tiny plants and take up less space than other varieties. Grit is removed using a vortex flow pattern in this kind. The wastewater enters tangentially and exits perpendicularly, either from the top or from the side.Grit particles will stay in the chamber due to inertia, while liquid devoid of grit will only exit.

Working of vortex flow grit chamber

The revolving turbine helps to separate organic materials and grit by maintaining a consistent velocity. By correctly supplying wastewater in the tangential direction in the chamber, the centrifugal force on the grit particle may be maintained without the need of a turbine. Because of the propeller's movement, grit particles follow a toroidal flow path. Gravity settles grit particles into a hopper, where they are removed by a grit pump or an air lift pump. This technology can produce washed grit that is devoid of biological materials.

To differentiate it from other types, a vortex flow type grit chamber can be stated as:

Sewage is injected in a tangential direction to form a vortex flow, which accumulates grit in the center and drags it down into the bottom chamber. In this type of grit chamber, an agitator is used to maintain the grit in suspension.

Conclusion

When sewage flow rates and durations are unexpected, this equipment comes in handy. Due to the vortex style of flow, the grit settles down and is then pumped or gravity drained onto a grit filter bed, which has a higher specific gravity of 2.4 to 2.65.

What can Netsol Water offer you?

Netsol is a leading name for the wastewater related units. We provide all the units tirelessly. With the best possible engineering solutions, we come with the best quality.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.