What is The Importance of RO Water for RMC Plant?

RO water for RMC plant matters more than many teams first expect. Concrete mixing centres face daily challenges in keeping mix quality uniform and meeting strength targets. Water acts as a chemical agent in concrete that controls hydration and workability. When water contains dissolved salts, organic matter or suspended solids, it changes how cement binds and how admixtures perform. Here you will find how RO treated water supplied by a Commercial RO Plant Manufacturer helps concrete strength, how it protects equipment, how it stabilizes production and how it supports compliance with customer and regulator needs.

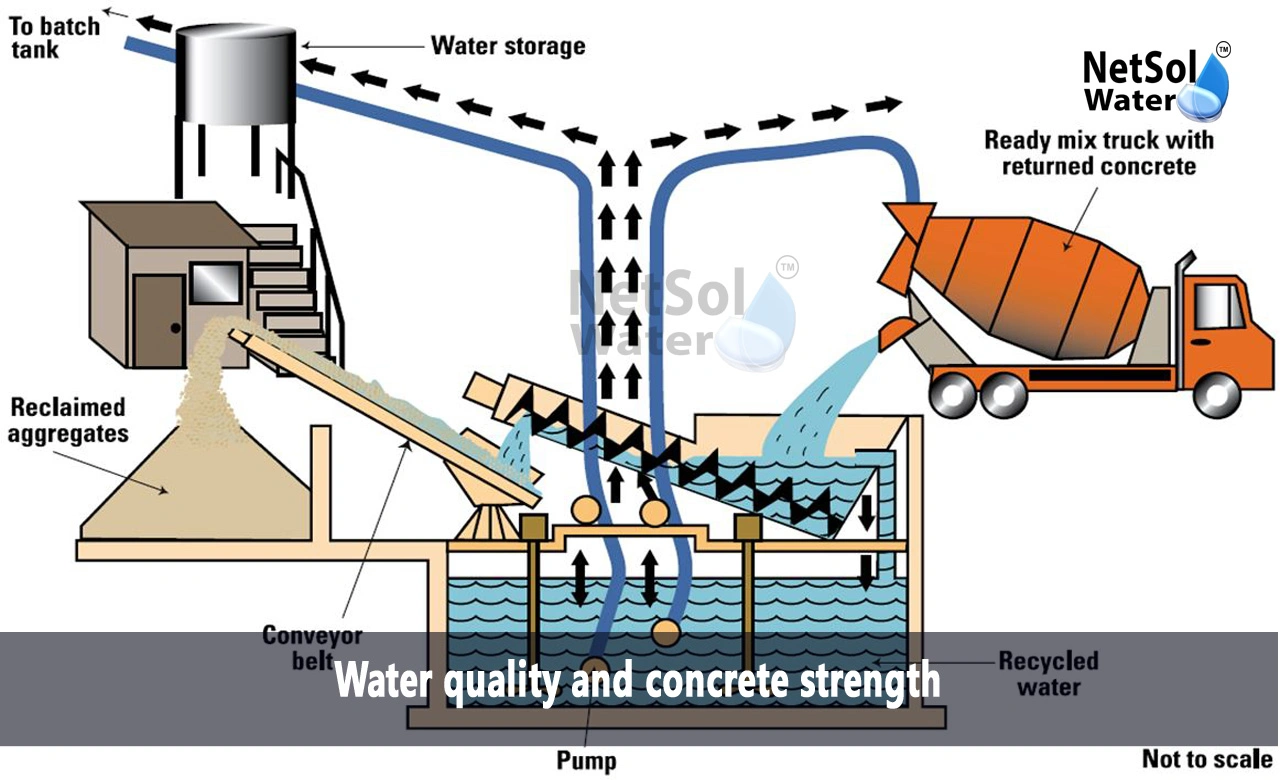

Water quality and concrete strength

Water quality links directly to fresh concrete performance and long term strength. Poor water contains salts and organic matter that change cement hydration and slow or speed reactions in uneven ways. These changes hurt early strength and final durability. Let us have a look on some factors that show why clean water matters.

1: Dissolved solids and their effect on cement

Dissolved solids change the chemistry of cement paste. When water contains chlorides or sulfates, it speeds certain reactions that lead to lower strength or to corrosion of steel in reinforced concrete. When salts enter the mix they can also change the setting time. Concrete may set too fast or too slow. Both cases create problems on site.

2: Organic matter and air entrainment

Organic matter in water can trap air or reduce entrained air stability. Entrained air helps concrete resist freeze and thaw cycles. When organic contamination increases air loss the concrete may become less durable over years of exposure. Using RO water removes organics and keeps air content stable.

3: Consistent water quality for consistent strength

Concrete strength depends on a consistent water-to-cement ratio. When water quality changes the effective water to cement behaviour shifts. That leads to batch to batch variation in compressive strength. RO water provides a predictable baseline. Plant staff can set mix designs and expect the same results each day. This control reduces the need for trial mixes at short notice on busy projects.

Scale formation and equipment life

Scale builds up inside mixers, pumps, pipes and dosing systems when hard water flows through them. Scale reduces flow and makes sensors give false readings. This problem increases maintenance time and reduces machine life. Let us have a look on some key ways scale forms and how RO water helps.

1: Mineral deposits in process equipment

Calcium and magnesium in feed water deposit as scale on metal surfaces. These deposits block nozzles and narrow pipe diameter. When scale forms mixers must work harder and pumps face extra wear. Removing scale needs mechanical cleaning or chemical treatment. Those tasks slow the plant and add cost.

2: Sensors and dosing systems

Dosing pumps and sensors work best when water has low conductivity. Hard water gives unstable sensor output and affects the accuracy of chemical dosing. When admixtures reach the mix in wrong amounts the concrete will not behave as designed. Reverse Osmosis water reduces the conductivity of feed water and keeps sensors accurate.

3: Reduced downtime and lower repair cost

When equipment stays free of scale, staff perform fewer repairs and call fewer service vendors. Reverse Osmosis water prevents the main cause of deposit buildup. This helps the plant keep daily output steady and lowers the total cost of ownership of mechanical systems.

Process control and admixture performance

Admixtures such as plasticizers, retarders and accelerators require predictable water chemistry to perform well. If water contains ions that interact with admixtures the admixture dose may stop working or overreact. Let us have a look on some examples that show how RO water supports chemical control.

1: Admixture chemistry and dosing accuracy

Many modern admixtures need low salinity water to extend slump or to maintain pumpability. When salts are present the admixture may bind to ions and lose its function. That forces field teams to increase addition rates. RO water prevents this waste. It keeps admixture action close to what mix designers expect.

2: Slump and workability control

Workability depends on water content and on admixture function. If water quality varies the same admixture dose will give different results. Operators face more rework and more site corrections. Using RO water makes slump targets repeatable. Teams deliver uniform concrete to the truck and to the job site.

3: Reduced chemical consumption

When admixtures work as designed, the plant uses less product to reach desired properties. Lower chemical consumption reduces cost per cubic meter and cuts the environmental burden from shipping and packaging. Clean water strengthens the link between design and outcome.

Health, safety and environmental compliance

Water quality affects the safety of onsite staff and the compliance status of plant discharge. Certain ions in water can lead to hazardous effluent after washing trucks or cleaning mixers. Let us have a look on some compliance areas that benefit from RO treated water.

1: Effluent composition and disposal

Wash water from concrete operations contains suspended solids and dissolved ions. If plant discharge contains high chloride or sulfate levels, local regulators may restrict disposal options. RO water reduces the salt load in wash water and makes it easier to treat or reuse onsite. That lowers disposal fees and reduces the risk of fines for non compliance.

2: Worker safety and hygiene

Cleaner process water reduces the risk of skin irritation during routine cleaning tasks. Hazardous salts or contaminated wash water can affect skin and eyes over time. RO water lowers those hazards and keeps maintenance tasks safer.

3: Environmental footprint and corporate responsibility

Plants that manage water with care show better environmental credentials. Treating water and reusing it reduces freshwater use and decreases the volume of contaminated wastewater. These actions help companies meet internal sustainability goals and show customers their commitment to better practices.

Cost savings and resource efficiency

Investing in RO plants requires capital and service. Yet the reductions in repair cost chemical use and water disposal often cover that investment quickly. Let us have a look on some cost items that change when a plant moves to RO treated water.

1: Lower maintenance and repair cost

Removing scale formation reduces the frequency of pump and mixer failures. Staff spend less time on emergency repairs. That lowers maintenance,labour, costs and reduces spare part consumption. Over a few years savings may cover the initial RO plant cost.

2: Reduced chemical and cement waste

When water quality stays stable admixture dosing becomes accurate. That cuts waste from overdosing. Stable mixing also reduces rejected batches. Lower waste means lower raw material cost per delivered cubic meter.

3: Water reuse and reduced supply cost

Reverse Osmosis plants pair well with collection and reuse systems. When a plant recycles wash water and polishes it with RO treatment it reduces fresh water draw. Lower water bills and lower disposal fees add direct savings each month.

Operational flexibility and product quality assurance

RO water helps plants respond to different project requirements with confidence. When the plant can hold water quality steady it can move mix designs between projects with minimal retesting. Let us have a look on some ways this flexibility shows on the ground.

1: Fast ramp up for new projects

When a plant starts work on a new contract it often needs to adjust mixes to meet local specifications. With consistent water the number of trial mixes drops. The plant can hit strength and slump targets faster. That improves delivery timelines and customer trust.

2: Ease of certification and testing

Quality teams perform fewer tests when variables stay stable. Lab work becomes easier and documentation looks better when water quality is not a variable. This benefits audits and customer acceptance tests.

3: Consistent finish and aesthetics

For projects that require exposed finishes, consistent water chemistry helps achieve uniform colour and texture. Variations in water can change the way pigments and cement create surface tones. RO water keeps those outcomes consistent.

Implementation considerations for RMC plant

Choosing an RO plant requires planning and good procedures. The plant must consider feed water quality, waste concentrate handling and maintenance. Let us have a look on the practical steps that reduce risk and speed adoption.

1: Assess feed water quality

Plants should test feed water for total dissolved solids, chloride, sulfate and organic load. These tests guide the size and design of the RO plant. Understanding seasonal variation in source water helps avoid undersized systems.

2: Plan concentrate handling

RO produces a reject stream that contains concentrated minerals. The plant must decide how to dispose or reuse this stream. Options include blending with other waste and treating it further. Planning this step prevents surprises at commissioning time.

3: Maintenance and spare parts

RO membranes need regular cleaning and occasional replacement. Plants should set service intervals and stock key spares. Training staff on basic RO checks reduces downtime and keeps water quality steady.

4: Integration with reuse systems

For best impact RO sits downstream of settling and filtration steps. A full reuse system captures wash water then polishes it with RO. This arrangement reduces solids load on membranes and extends membrane life.

Quality documentation and customer assurance

High quality mixes require records that prove consistency. RO water supports stronger documentation and clearer technical responses to clients. Let us have a look on how documentation improves trust.

1: Batch records and water logs

Recording water quality each day shows how the plant controls key inputs. When customers ask for proof of mix conditions the plant can present water logs along with compressive strength data. These records reduce disputes and speed acceptance.

2: Transparency in specification

When mix designs state the water standard the plant and its clients share a clear expectation. Including a note that the plant uses RO water for critical mixes helps avoid surprises. Customers then know the basis of design and testing.

3: Support for warranty claims

If a client raises a durability concern, the plant can show that water quality remained within set limits. This evidence helps resolve issues fairly and reduces long term liability.

Conclusion

RO water for RMC plant gives clear benefits that show in strength in cost in maintenance and in client trust. Clean water supports consistent chemistry and steady production. It lowers repair work and reduces chemical waste. It improves compliance and reduces environmental impact. Plants that treat and control their water gain predictable results that help them win repeat business. If you want a review of your current water use or a simple plan for trialling RO at your plant get in touch for a consultation. We can provide a practical assessment and a plan that fits your site and your budget.

Contact Netsol Water at:

Phone: +91-9650608473, Email: enquiry@netsolwater.com