Effects of Using RO Water on The Quality of Concrete in RMC Plant

Water plays a direct role in the formation and performance of concrete because it reacts with cement during hydration and also affects fresh and hardened properties. In ready mix concrete plants the source and quality of water can vary based on location and availability. Many plants now use reverse osmosis-treated water supplied by a Commercial RO Plant Manufacturer to control impurities present in natural or municipal water sources. RO water passes through membranes that remove dissolved salts minerals, chlorides, sulfates and other unwanted substances. This process produces water with very low total dissolved solids (TDS) and a different chemical balance when compared to regular potable water. Water interacts with cement in many ways and it also changes how admixtures work and how concrete cures. A change in water can change workability, setting time, strength and long term durability.

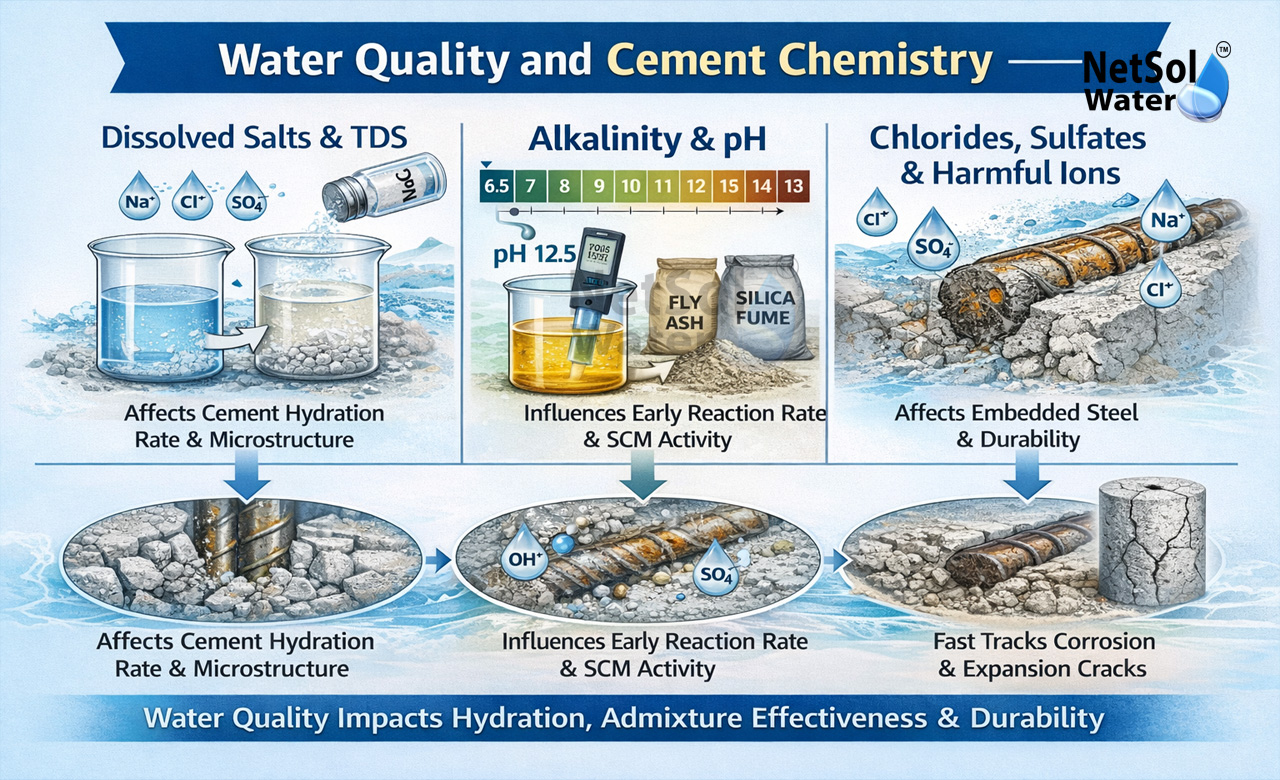

Water quality and cement chemistry

Water forms a chemical partner with cement in concrete and its make up can speed up slow down or alter the hydration reactions. Let us have a look on some

1: Dissolved salts and total dissolved solids

Different waters contain different dissolved salts and minerals. These salts change the rate at which cement hydrates and they can alter the microstructure that forms in the first days. Reverse Osmosis water typically has low total dissolved solids and low ionic content when compared to many sources. Low dissolved solids can reduce unwanted side reactions that form surface layers around cement grains and this can help cement hydration proceed in a more uniform way. Some studies show improved early strength when RO water replaces high TDS water.

2: Alkalinity, pH and chemical balance

Cement hydration creates a highly alkaline pore solution. Mixing water with very low alkalinity does not prevent hydration but it can change the initial ionic balance in the pore fluid. This shift can modulate the speed of early reactions and can alter the way some supplementary cementitious materials contribute. When RO water has very low buffering capacity the mix can become more sensitive to small chemical additions. Careful trial mixes help reveal these differences.

3: Chlorides, sulfates and harmful ions

Water can carry chloride and sulfate ions that attack steel or create expansive products in concrete. RO treated water usually removes most of these ions from the feed water stream. Removing these ions reduces risk to embedded steel and lowers risk of sulfate related expansion. This effect improves durability when the water source otherwise contains moderate to high levels of these ions.

Workability and setting time

Workability determines how easy it is to place and compact concrete and setting time sets the window for finishing and early curing. Let us have a look on some

1: Effect on slump and flow

Water with low dissolved solids behaves like soft water during mixing. Concrete mixed with Reverse Osmosis water often shows a slightly different slump than the same mix with tap water when the water cement ratio stays constant. Often the mix with RO water feels more fluid for the same water content because salts and minerals that can affect particle interaction are reduced. Plant trials can identify whether a small water adjustment or a minor admixture dose change can stabilise the slump.

2: Effect on initial set and finishing time

RO water can change the initial set by altering the early hydration rate. In some tests mixes with RO plant water show faster initial set in the first hours. In other tests the change is small and within normal variation. The key is to test the actual cement and admixture combination that the plant uses and to monitor finishing and curing windows on site.

3: Interaction with water reducing admixtures

Many chemical admixtures work by interacting with ions and particle surfaces in mix water. When water contains few ions the dispersion action of some admixtures can change. This can cause small differences in the air content flow and slump retention. Trial batches reveal whether the admixture dose needs fine tuning for consistent workability.

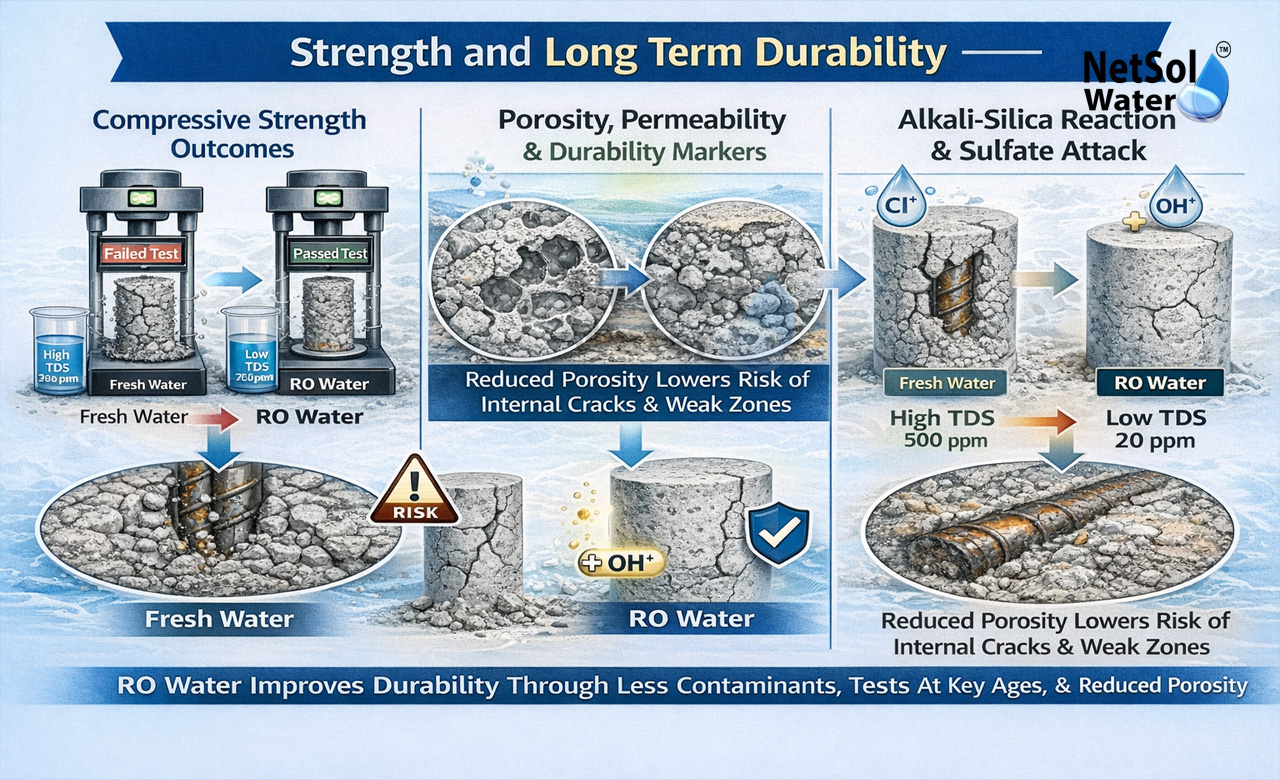

Strength and long term durability

Strength and durability determine the service life of concrete structures and they influence design choices. Let us have a look on some

1: Compressive strength outcomes

Multiple studies report mixed outcomes when RO water replaces potable water. Some trials show improved early age strength and similar 28 day strength. Some trials report slightly lower 28 day strength. The differences often trace back to feed water quality cement type and curing regime. The safest approach uses comparative strength tests at relevant ages before large scale use.

2: Porosity, permeability and durability markers

Concrete porosity and permeability control how environmental agents enter concrete. RO water often lowers the amount of extraneous ions that can create secondary reaction products and this can reduce risk of unwanted internal reactions. When feed water contains impurities those impurities can raise porosity or create micro defects. Using Reverse Osmosis water can therefore help lower permeability in some cases especially when the alternative water had elevated contaminants.

3: Alkali silica reaction and sulphate attack

Water chemicals can either feed or starve deleterious reactions. RO water that removes aggressive ions reduces the chance of sulfate attack and of accelerating alkali silica reaction through extra alkalis. Still the overall alkali budget in concrete comes mainly from cement and other binders so water contribution is only one part of the picture. Testing helps confirm the net effect for a given mix.

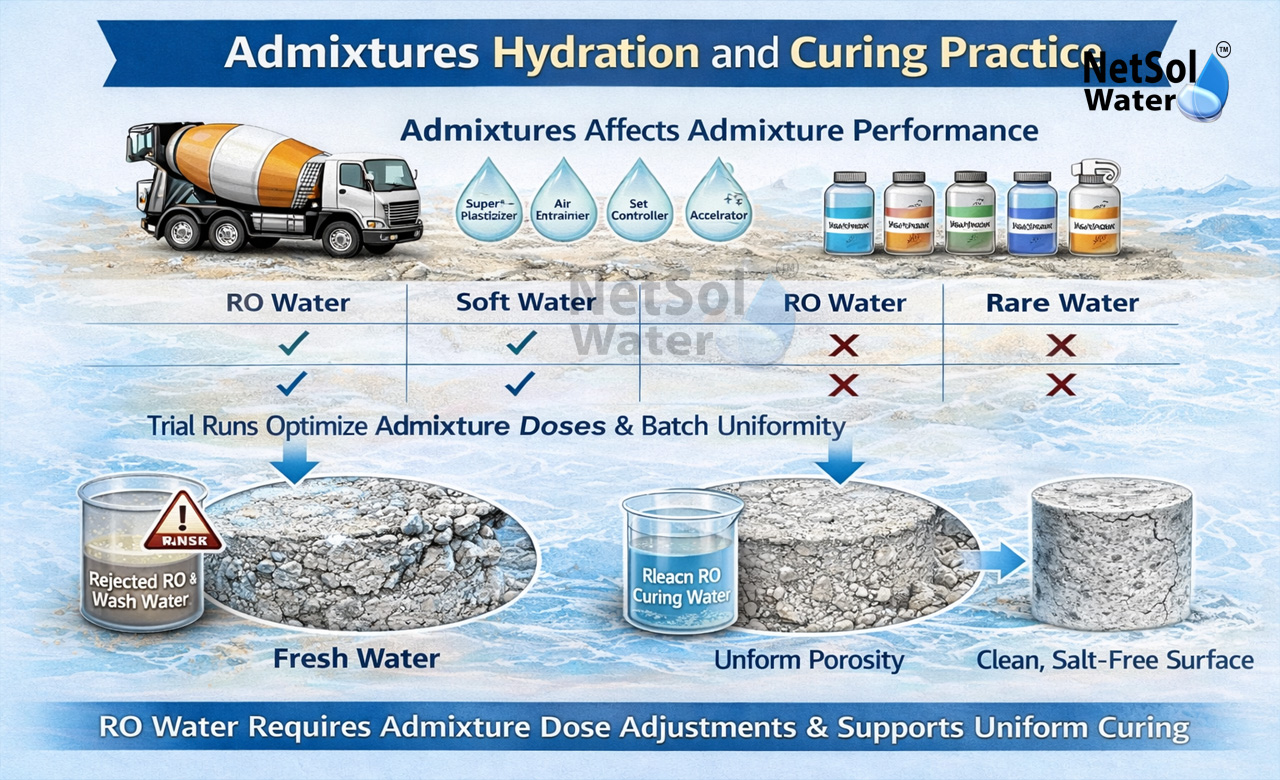

Admixtures hydration and curing practice

Admixtures and curing shape the microstructure during the first crucial days and weeks. Let us have a look on some

1: How RO water affects admixture performance?

Superplasticisers air entrainers set controllers and accelerators rely on predictable water chemistry. When RO water lowers the ion count some admixtures gain effectiveness and some lose part of their action. For example dispersant based superplasticisers can show altered dosage response with very soft water. The plant should perform dose response curves under plant conditions to set optimum doses and to maintain consistent air content and workability.

2: Curing with RO water

Curing keeps hydration alive and reduces shrinkage cracking. Using RO water for curing reduces the risk of depositing salts on the surface that sometimes occur with poor quality curing water. Clean curing water helps achieve uniform strength development and reduces surface staining. However when the plant uses RO concentrate or rejects for other tasks the plant must avoid cross contamination of curing water.

3: Timing of testing and gradual change

When a plant moves to RO water it should stage the change. Start with trial batches then move to small production runs then carry out compressive strength tests and durability checks. This phased approach reduces the chance of production pauses and ensures admixture doses and water cement ratios stay correct.

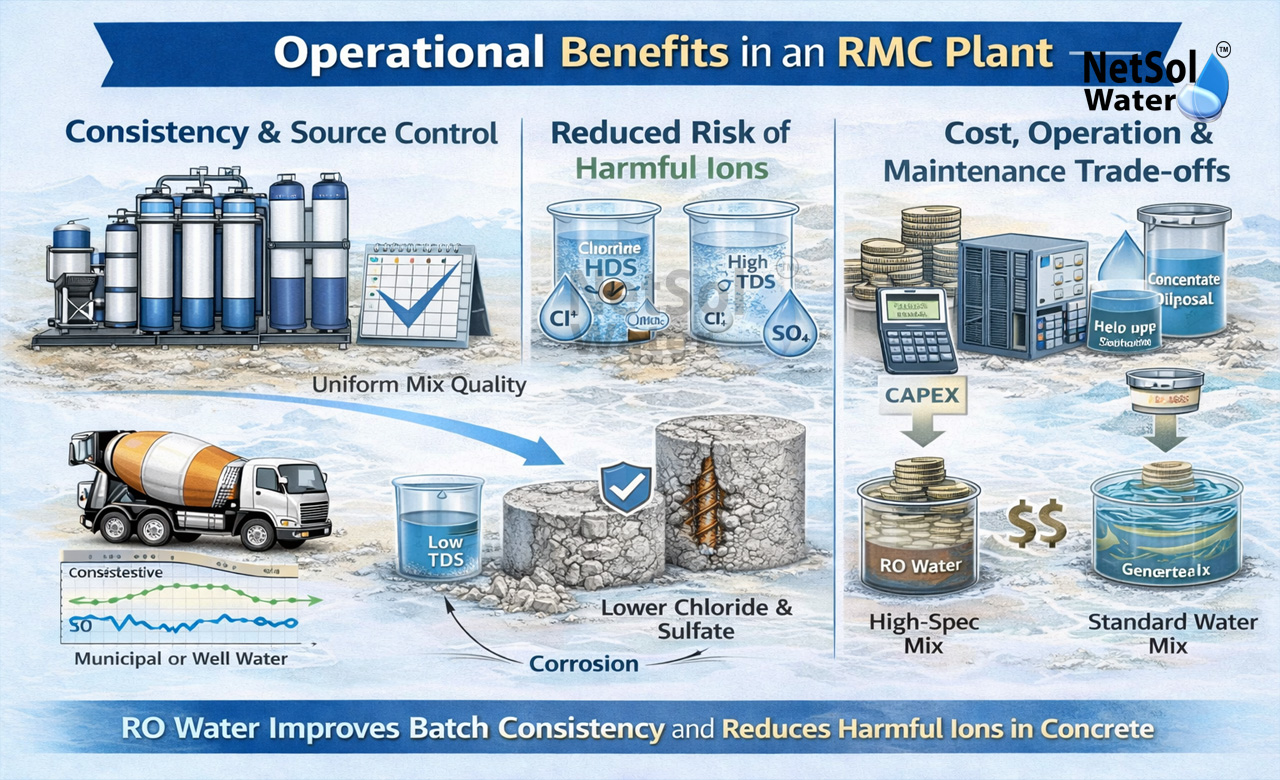

Operational benefits in an RMC plant

Plant scale matters in cost quality and compliance. Let us have a look on some

1: Consistency and source control

RO plants deliver consistent water quality compared with wells river water or variable municipal supplies. Consistent water helps deliver more uniform concrete across batches and across days. When plants control their water quality they also reduce variation in fresh properties and hardened properties. This consistency makes quality control more predictable.

2: Reduced risk of harmful ions

Using RO water reduces chloride and sulfate levels in mix water when the feed water carried these ions. This effect lowers risk to embedded steel and reduces long term repair needs. For precast or high performance mixes where chloride limits matter RO water can be a practical way to meet specification limits.

3: Cost operation and maintenance trade offs

RO plants have purchase and running costs and they produce concentrate that needs disposal. Plants must weigh the improved control over water quality against these costs. In some cases plants choose partial use of RO water for high specification mixes and they use standard water for generic mix types. That hybrid strategy keeps costs manageable while improving performance where it matters.

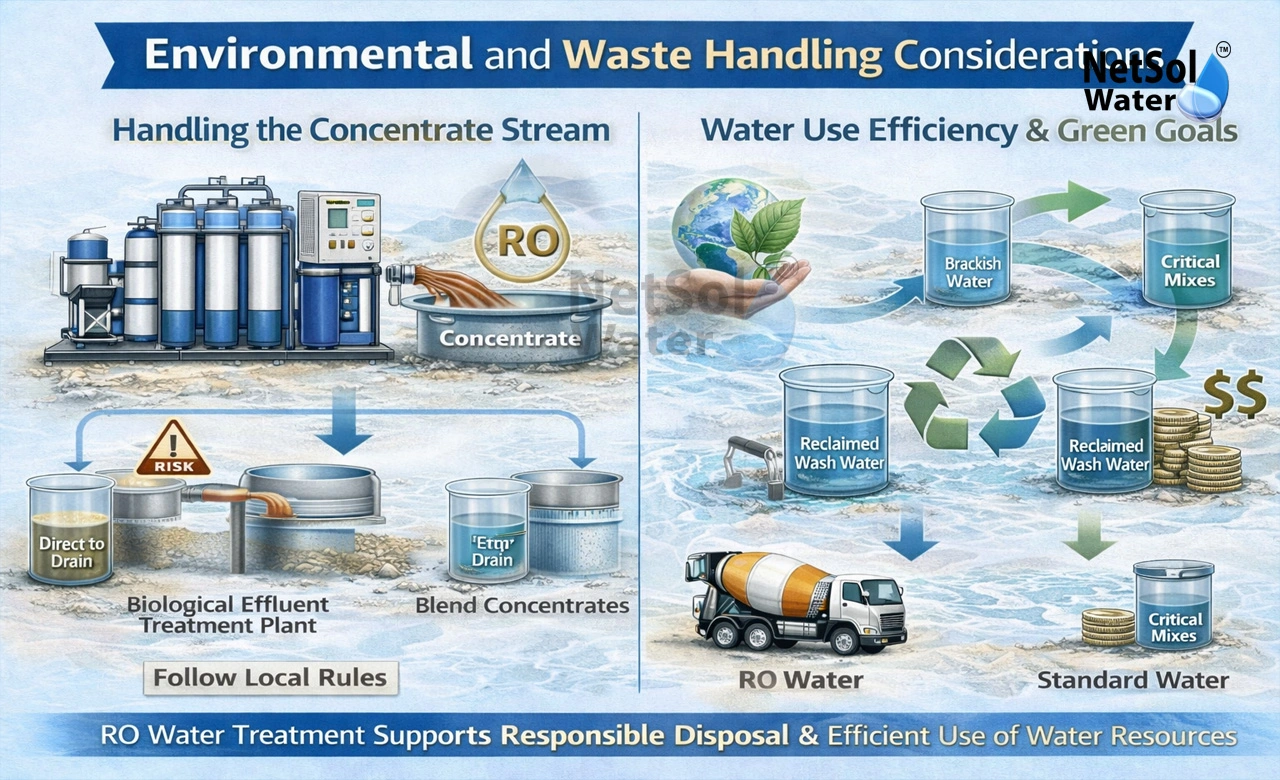

Environmental and waste handling considerations

Reverse Osmosis plants create a concentrate stream that carries higher salts and contaminants.

1: Handling the concentrate stream

RO plants send reject water to drains or to treatment. That concentrate can carry concentrated salts or organics. Plants must avoid direct discharge to sensitive drains and they should follow local rules for disposal. Some plants blend the reject with other streams or send it for further treatment. Planning for concentrate handling reduces the chance of regulatory fines or damage to local systems.

2: Water use efficiency and green goals

Using RO water can support water efficiency when the plant uses brackish or marginal water as feed and then reclaims a portion of it for critical mixes. Recycling wash water and blending with RO treated water can also reduce fresh water demand. That approach improves sustainability and can lower net costs when implemented with care and tests.

3: Health safety and site practice

RO plants require filters membranes and chemical cleaning. The plant should train staff on safe handling of cleaning chemicals and on routine checks of water quality. Regular testing of the mixing water ensures no sudden change degrades concrete quality.

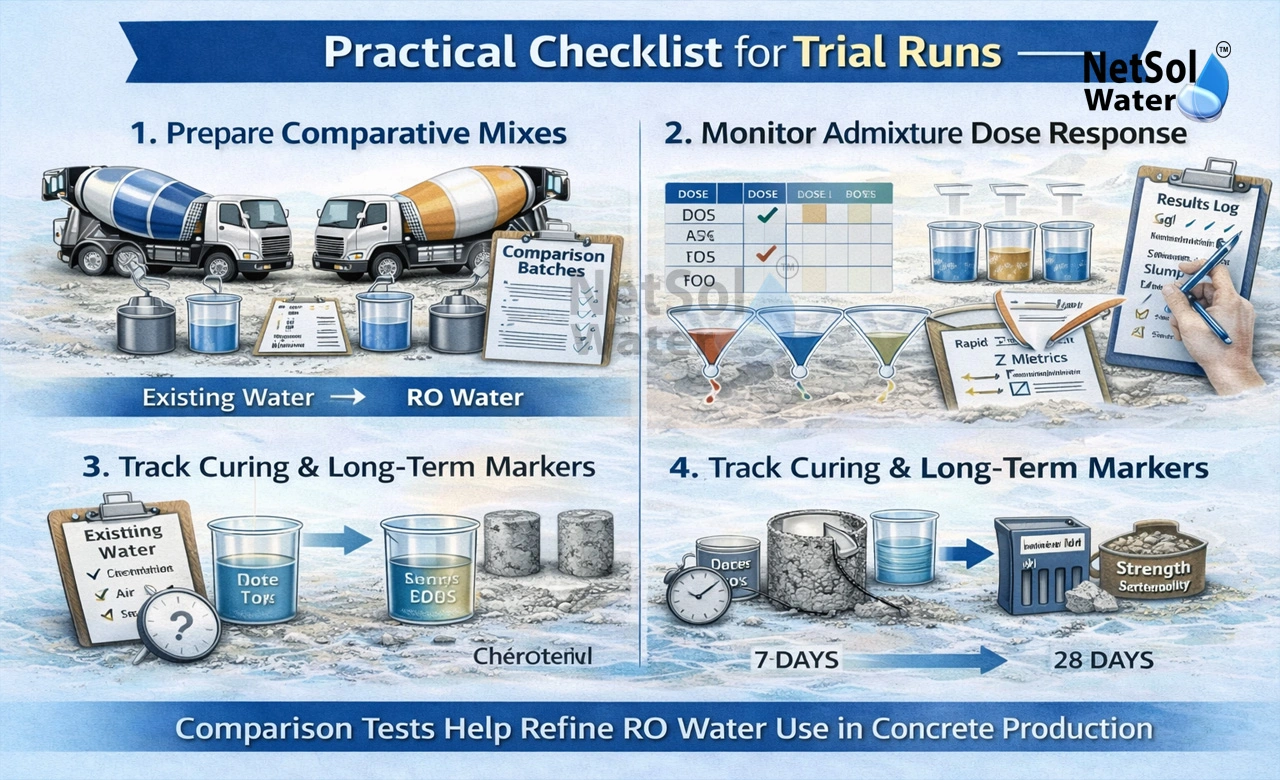

Practical checklist for trial runs

Before full scale change perform focused trials and record results. Let us have a look on some

1: Prepare comparative mixes

Make side by side batches with existing water and with RO water. Use the same mix design admixture and batching procedure. Test slump air content and compressive strength at selected ages. This direct comparison reveals differences that are meaningful for the plant.

2: Monitor admixture dose response

Run a small matrix of admixture doses with RO water to find the dose that gives the target slump and air content. Keep records and update production mix sheets accordingly.

3: Track curing and long term markers

Cure samples in controlled conditions and test permeability and compressive strength at 7 days and 28 days. If possible run simple durability tests like rapid chloride permeability or water absorption. These tests show whether the mix performs well under realistic exposure.

Conclusion

Using treated water from reverse osmosis systems changes concrete behaviour in ways that can help or harm performance depending on feed water cement and admixtures. When teams ask What is the effect of using RO water on the quality of concrete in an RMC plant they find that careful testing and staged implementation deliver the best results. Start with small trials measure fresh properties and hardened properties and adjust admixture doses and water cement ratio as needed. If you want practical help to design trials or to interpret test data please get in touch or request a consultation.

Contact Netsol Water at:

Phone: +91-9650608473, Email: enquiry@netsolwater.com