What is Subsurface Wastewater infiltration system?

SWISs (subsurface wastewater infiltration systems) are most often employed systems for onsite wastewater treatment and dispersion so that wastewater can permeate and percolate through the underlying soil to the ground water. Infiltrative surfaces are situated in permeable, unsaturated natural soil or imported fill material. The wastewater is treated by a range of physical, chemical, and biological processes as it infiltrates and percolates through the soil.

Primary steps in sub-surface wastewater infiltration systems

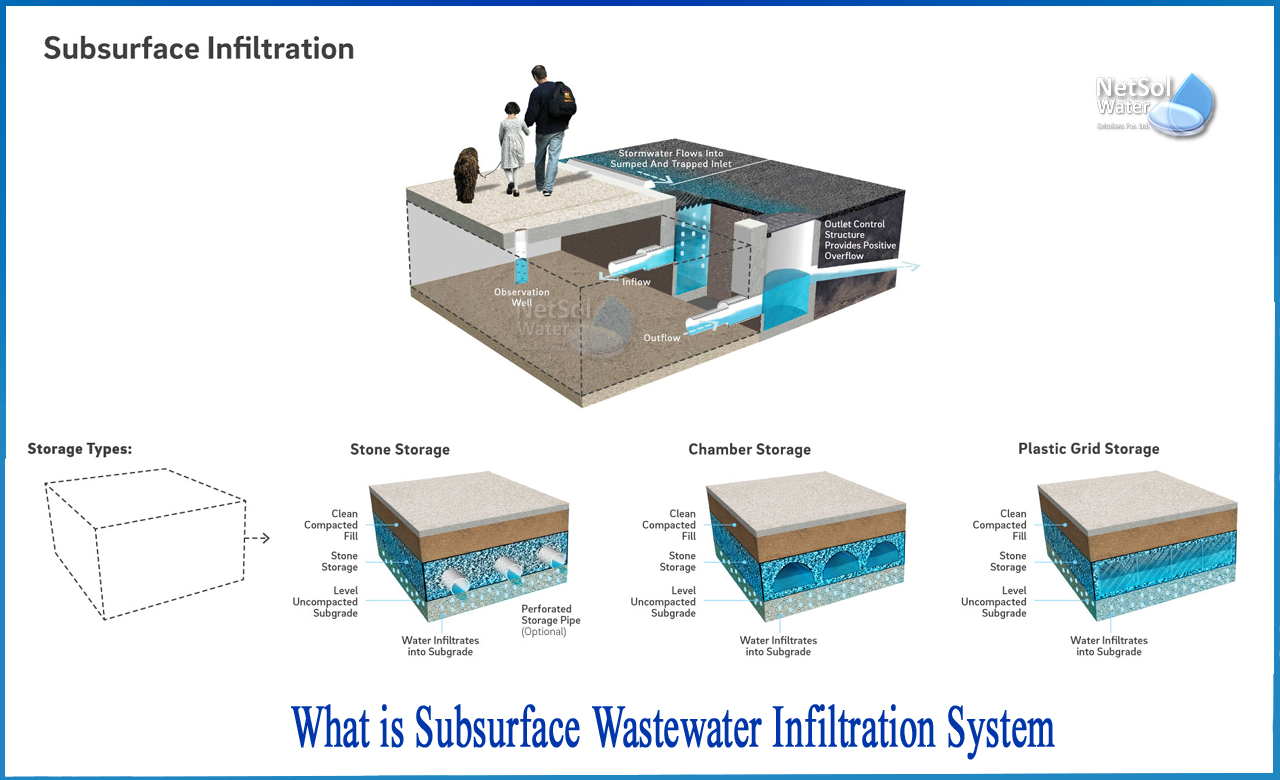

There are many various designs and combinations, but they all include soil infiltrative surfaces in buried excavations. The bottom of the excavation is the primary infiltration surface, although the sidewalls can also be used for infiltration. The wastewater is distributed across the infiltration surface using perforated pipes. To support the pipe and diffuse the confined flow from the distribution pipes over the excavation cavity, a porous material, often gravel or crushed rock, is put in the excavation below and around the distribution pipework.

Other gravelless or "aggregate-free" system components might be used in place of the gravel. During peak flows with gravity systems, the porous medium preserves the structure of the excavation, exposes the applied wastewater to a more infiltrative surface, and offers storage room for the wastewater within its void fractions (interstitial gaps, generally 30 to 40% of the volume). Before the excavation is backfilled, a permeable geotextile cloth or other appropriate material is put over the porous medium to prevent backfill material from entering the porous medium. Backfilling is normally done with natural soil, and the surface is usually gently mounded and sown with grass.

Working of the sub-surface wastewater infiltration systems

The applied wastewater is dispersed and treated using subsurface wastewater infiltration systems. Wastewater is conveyed through three zones from the infiltration system.

The infiltration zone and the vadose zone both function as fixed-film bioreactors. The infiltration zone, which is just a few centimetres thick and is commonly referred to as the "biomat," is the most biologically active zone.

Carbonaceous material in the wastewater degrades fast in this zone, and if there is enough oxygen, nitrification happens directly below it. The oxygen demand created by the microbes decomposing the materials must be met by free or mixed forms of oxygen in the soil.

If there isn't enough oxygen, microbes' metabolic activities might be slowed or stopped, affecting both wastewater treatment and infiltration.

Design considerations of subsurface wastewater infiltration systems

SWISs come in a variety of shapes and sizes.

1: Trenches, beds, seepage pits, at-grade systems, and mounds are among them. The shape and position of SWIS applications in the soil profile varies. Trenches feature a considerable length-to-width ratio, whereas beds are rectangular or square in shape. Seepage pits are large, circular excavations that rely nearly entirely on infiltration from the sides.

2: The majority of conventional systems are built under the ground surface in natural soil. A restrictive horizon above a more permeable horizon may be removed in some cases, and the excavation is filled with suitable porous material to form the infiltration surface. Infiltration surfaces can be built at ground level ("at-grades") or elevated above the natural soil surface ("mounds") using imported fill material.

The creation of a secondary infiltrative surface (which must be addressed in design) at the fill/natural soil boundary is a significant distinction between infiltration surfaces developed in natural soil and those constructed in fill material. Despite the variances in the kinds of SWISs, the treatment and dissemination methods are comparable.

Feel free to contact Netsol Water with any queries you may have about custom-designing and manufacturing water or wastewater treatment systems. Contact us at +91 9650608473 or contact via email at enquiry@netsolwater.com for additional information.

You may also schedule a conversation with an engineer or obtain an estimate by visiting our website. We can guide you through the process of determining the best solution and realistic pricing for your wastewater treatment system requirements.