What is Submerged Aerated Filter technology?

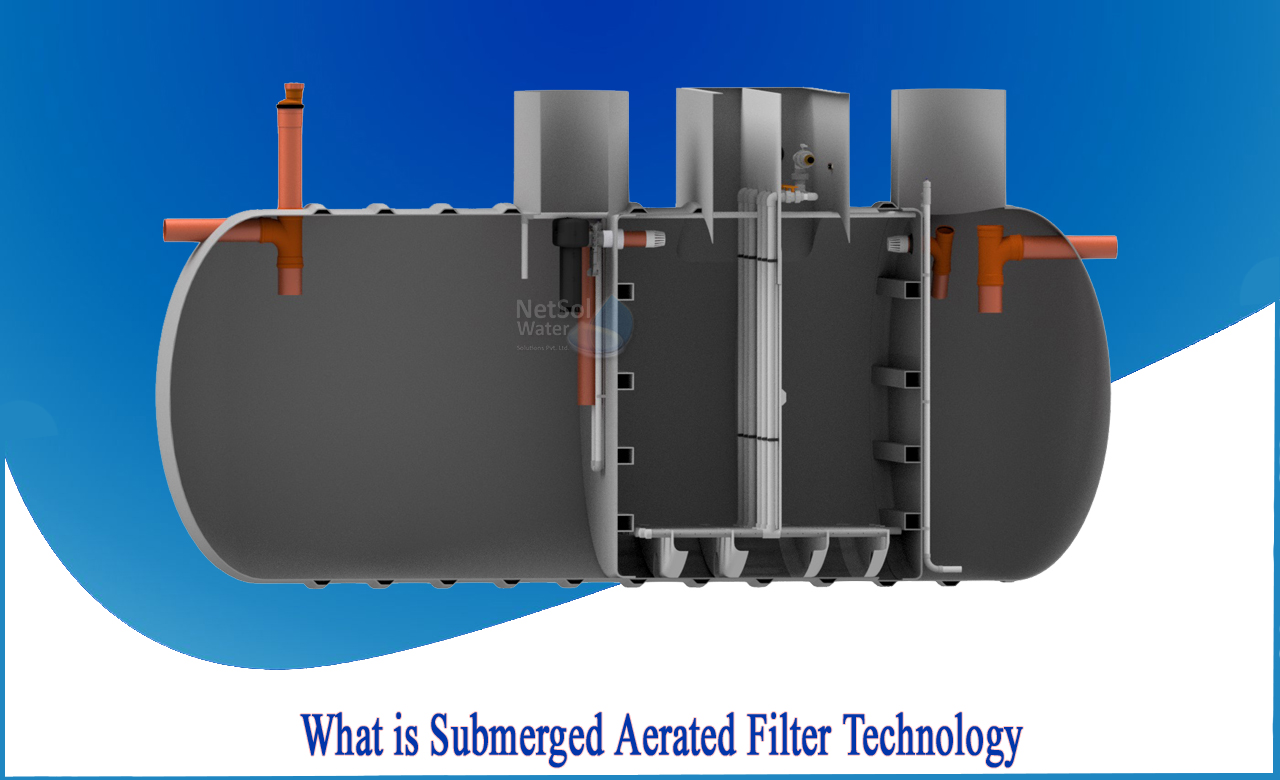

The SAF is an up-flow bioreactor that uses a neutral buoyancy plastic media with high efficiency. The Submerged Aerated Filter is made up of a containment vessel made up of coated mild steel, stainless steel, GRP, GCS, or concrete that has internal dividing walls, internal air and water distribution systems, a charge of plastic media, and an internal support structure. The media provides more space for bacteria to attach themselves to in order to grow and live.

Modes of aeration:

Diffuser systems for aeration take up space in the reactor and are installed directly below the filling media. The oxygen supply and internal recirculation that allows repeated contact with aerated biofilm wastewater are achieved through air diffusion.

There are several types of aeration:

(1) Central aeration, in which air diffuses from the vertically positioned shaft tube, resulting in a radial recirculation flow;

(2) Uni-directional recirculation, in which diffusers are already installed along one of the reactor walls.

(3) Bidirectional recirculation, with air diffusers installed along the reactor's centre line.

(4) Air bubbles can also be introduced directly through the bed. In one case, air is circulated into a bed zone, forming a recirculation flow in the reactor, whereas in another, air is introduced uniformly distributed throughout the reactor.

Operation of submerged aerated filter:

The operation of a submerged aerated filter (SAF) is based on the passage of pre-treated or settled wastewater through a filter bed where a bacterial culture known as biofilm degrades dissolved organic pollution. A portion of the suspended solids and colloids are also adsorbed by the biofilm and thus removed from the wastewater. Submerged beds have the following advantages:

· Stable operation

·Simple operation even used for detached houses

·It does not require sludge return or recirculation unlike suspended biomass processes.

Waste Water Characteristics:

The following pollution parameters are associated with the operation and design of submerged aerated filters:

• Suspended solids

• Micronutrients

• Restrictors

• pH, temperature, and so on.

To avoid bed clogging, a prior reduction of suspended solids is critical, especially when a high surface area support media is used. However, physical suspended solids removal increases the overall sludge production system because a portion of these solids constitute organic substrate when no pre-treatment is used.

Sludge production can be reduced by anaerobic hydrolysis of the suspended solids removed during physical pre-treatment, with the liquid phase product feeding the submerged bed.

Septic tank + submerged aerated filter or anaerobic filter + submerged aerated filter combinations will reduce sludge production in the case of small flows. Biofilm systems are generally more resistant to the presence of inhibitory substances. They are also more resistant to abrupt pH changes. Furthermore, because the bed is immersed, it is less susceptible to changes in ambient temperature.

Features of SAF Technology:

• Compact footprint

• Low environmental impact

• Minimal manpower & energy requirements

• Established/robust fixed film technology

• Resistance to shock and toxic loads

• Suitable for below ground, partially buried, or above ground installation

• Simple to operate

• Low maintenance

• Low whole life costs

• Computer software designed to provide accurate sizing and guaranteed effluent discharge quality

Conclusion

The best manufacturer of water treatment solutions is NETSOL WATER.

SAF (Submerged Aerated Filters) are NETSOL WATER TECHNOLOGY's preferred technology, particularly when organic material in the water (BOD and COD reduction) or ammonium NH4 reduction is required.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.