What is Step feed Multistage Biological Nitrogen Removal Process?

Nitrogen removal can be accomplished by physical-chemical processes (e.g. breakpoint chlorination or air-stripping) or biological mechanisms. Because alternative methods may not be as cost-effective for high-strength wastes (e.g., meat-packing, poultry), biological nitrogen removal is more widely utilized in industrial wastewater treatment.

If the wastewater includes organic nitrogen, it will need to be deaminated before it can be converted to ammonia.

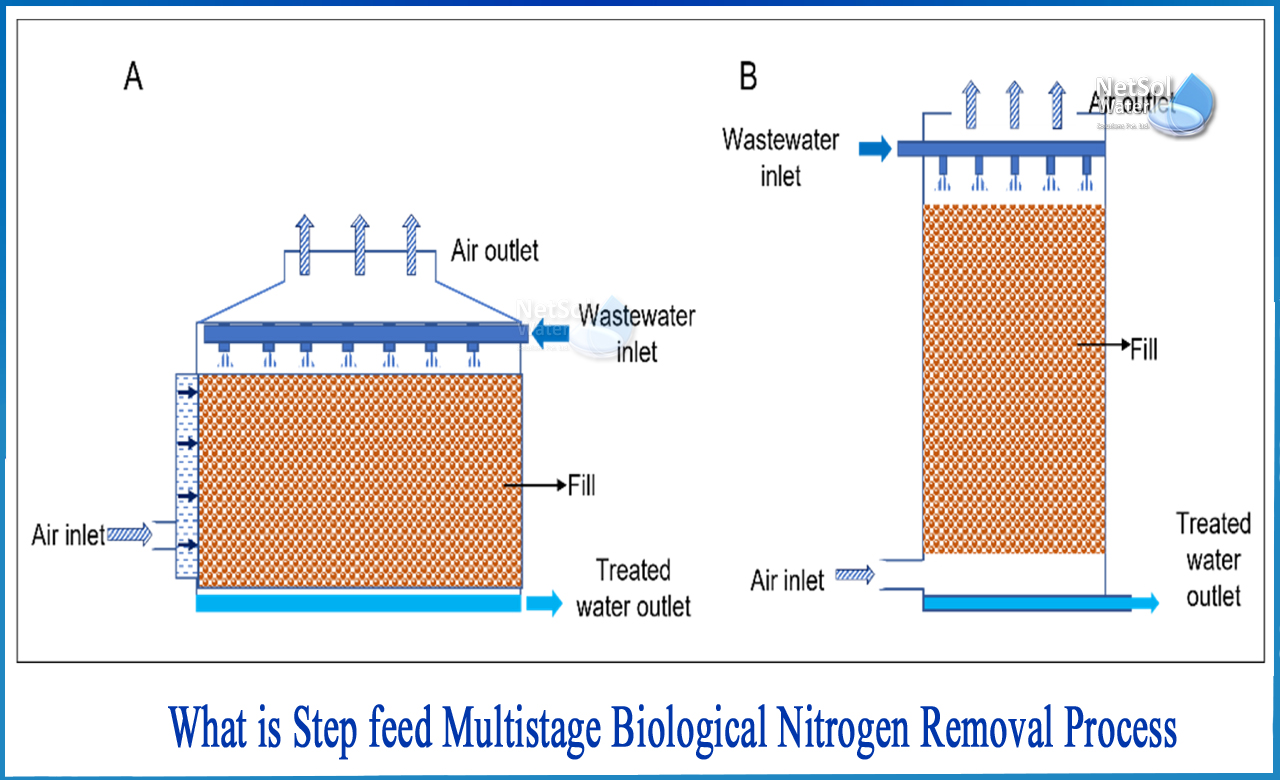

Biological Nutrient Removal in Multi-stages

The step-feed activated sludge method is a plug-flow process, which means that the RAS enters the reactor's head end and the particles in the fluid ideally leave the reactor in the same order that they entered.

In the step-feed procedure, influent wastewater is fed into the biological reactor in stages, allowing readily biodegradable organic material to be accessible for denitrifying bacteria in several compartments. If nutrient removal is to be included, the basins are separated into numerous zones with differing biochemical conditions, much like the standard activated sludge process.

The step-feed BNR (Biological Nitrogen Removal) technology is implemented in full-scale facilities for effective nitrogen removal and may be accomplished without nitrate recirculation since the nitrate created during denitrification can be oxidized in the following nitrification zone.The reduced recirculation of nitrate lowers the plant's total operating expenses.

Advantages of Step-Feed Multistage Biological Nitrogen Removal Processes

Several advantages of the step-feed process have been found in full-scale, pilot-scale, and theoretical studies.

1:Aside from lowering energy consumption by reducing the need for pumping, step-feeding creates a concentration gradient of MLSS in the tank. At the reactor's head end, the return sludge will only be partly diluted with the entering wastewater, and the MLSS will be greater in the early compartments.This means that, as compared to a standard plug-flow system, the average MLSS in the tank may be higher in the step-feed process without raising the solids loading to the secondary clarifier, and SRT is thus enhanced.

2:Because of the MLSS gradient across the tank, more wastewater may be treated within the same reactor capacity, resulting in a 35–70% increase capacity. Return activated sludge (RAS), Waste activated sludge (WAS) and Effluent wastewater facilities may be built with no effect on clarifier load. Reduced SS loading to the clarifier also results in more stable settling conditions since there is less chance of bulking sludge.

3:Because not all of the wastewater enters the tank in the same zone, the F/M loading is lower than with conventional plug-flow, lowering peak oxygen demand and making the system more capable of managing large organic loads. Incoming wastewater division can also be advantageous to the microbial population since it lowers the harmful impacts of hazardous chemicals.

4: It also has the ability to protect the biomass from wash-out during high flows by lowering the influent flow to the first denitrification zone. As a result, some plants shift their feeding site prior to rainy weather flows.

If you want to know more about Netsol’s range of Sewage Treatment Plants for Industrial or Commercial purposes, thenyoucan have an expert solution upon contacting Netsol Water Solutions, a leading manufacturer of Industrial and Commercial Water Treatment Plants and Wastewater Treatment Plants, among other services. Our treatment systems are very effective at removing all types of chemical, physical, and biological pollutants.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.