What is sludge disintegration?

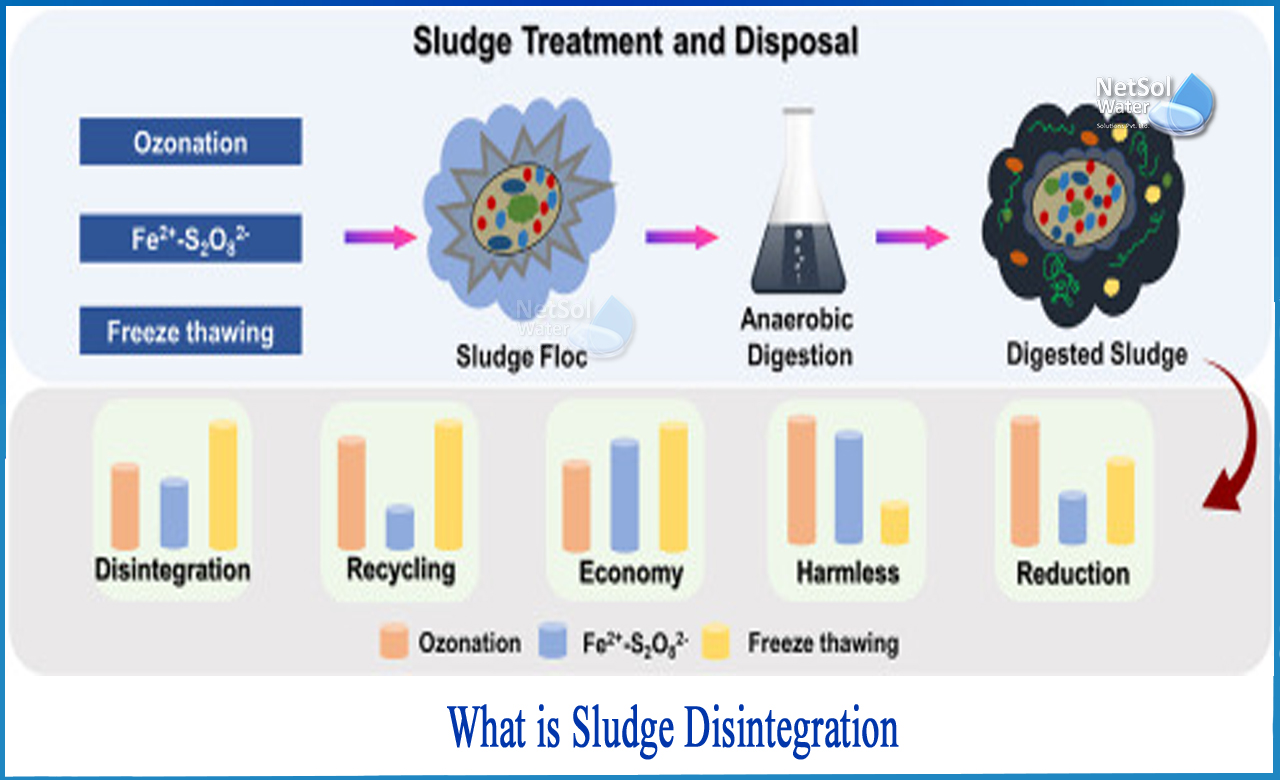

Sludge disintegration technologies are pre-treatment processes that reduce sludge mass or improve sludge characteristics and are integrated into sludge handling units.

What are the four types?

Mechanical disintegration, thermal disintegration, chemical or thermo-chemical disintegration, and biological disintegration are the four types of sludge disintegration methods designed to eliminate excess sludge. Integration of these technologies into sludge handling systems at the lab, pilot, and full scale has been found to significantly reduce sludge.

Are these technologies environmental friendly?

Sludge disintegration technologies are considered environmentally friendly because they generate no new waste that is hazardous to the environment. As a result, sludge minimization has gotten a lot of attention in the previous few decades.Sludge management is a key concern for wastewater and/or sludge treatment plants, and sludge disposal regulations are growing stricter. Sludge is made up of wastewater treatment plant processing by-products.

Because of stricter regulations for wastewater treatment plant effluents and the development of new wastewater treatment plants in developing nations, the worldwide quantity of sludge is likely to increase in the future. On a global scale, the cost of dewatered sludge disposal can be up to 50% of the overall plant management cost, including energy, labour, and routine maintenance.

Several new treatment techniques for wastewater and sludge have been developed in recent decades, but many of these procedures are quite expensive and have low operational efficiency. Globally, research is being conducted to identify effective treatment methods. Sludge minimization, rather than sludge recycling and re-use, is the recommended alternative for sustainable development. Sludge disintegration technologies are regarded as environmentally friendly because they generate no new trash or gas.

How is sludge minimization achieved?

For sludge minimization, disintegration technologies that may be integrated into wastewater or sludge-handling equipment have been developed.Sludge disintegration technologies built into sludge handling units are pre-treatment techniques that improve the efficiency of future sludge handling steps.

The hydrolysis step, also known as the speed-limiting stage, in the stabilisation process, which is one of the most critical of sludge handling units, is fairly slow, and organic matter is not totally destroyed. As a result, sludge disintegration technologies were created in order to improve the stabilisation process.

Sludge solubilization rises as a result of improved stability, resulting in total solids decrease and surplus sludge minimization. Excess sludge reduction is the primary goal of sludge disintegration technologies integrated into sludge handling machines, since it lowers the cost of waste sludge disposal.

Sludge solubilization, floc size reduction, microorganism damage or lysis, release of intra- and extracellular constituents, improved sludge biodegradation, digester volume reduction, and increased biogas production are all effects of sludge disintegration technologies integrated into sludge handling units. Sludge dewater ability increases as a result of the release of intra- and extracellular components as well as bound water. When the solids content in the dewatered cake grow, the cost of disposal of dewatered sludge reduces.

Conclusion

The pathogen inactivation processes utilised in sludge disintegration are effective, and the dewatered sludge can be used for agricultural or land uses. Sludge disintegration technology combined into sludge handling systems reduce sludge mass dramatically.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.