How is Power generated from Dairy Industry?

Every year, global energy consumption rises. Fossil fuels account for over 86 percent of global energy output. As a result of the severe energy crisis that both developed and developing countries are experiencing, many sources of energy are in great demand. Furthermore, because of international environmental concerns and energy instability, there is a growing interest in finding property and clean energy sources that use less or no hydrocarbons.

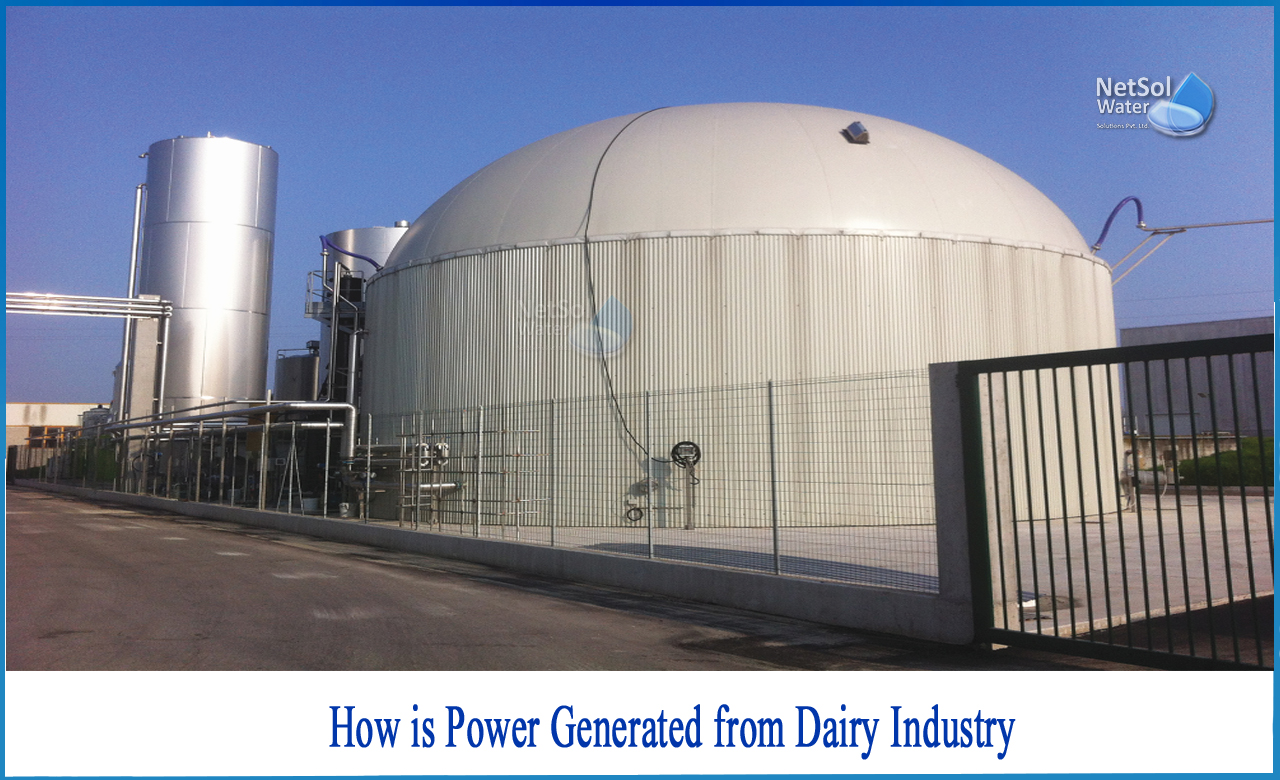

Dairy Wastewater Treatment

Grease traps, oil-water separators to remove floatable solids, flow equalization, and clearers to isolate suspended solids, are all popular wastewater treatment technologies in the dairy industry.

Aerobic and anaerobic techniques are used in biological treatment. To reduce soluble organic matter (BOD), anaerobic treatment combined with aerobic treatment is employed, and to raise nitrogen and phosphorus levels, a reduction of biological nutrients (BNR) is used.

Activated sludge, batch sequencing generators, revolving biological contactors, trickling pipes, aerated lagoons, or a combination of these are used in the traditional aerobic treatment of dairy effluent.

Anaerobic wastewater treatment has developed as a viable and cost-effective alternative to aerobic wastewater treatment, particularly for high BOD reduction. Up-flow anaerobic sludge blankets (UASB), anaerobic batch sequencing reactors (ASBR), continuous-flow reactors, hybrid anaerobic digesters, up/downflow anaerobic filter, and numerous 2-stage procedures that utilize acid and methane producing bacteria are examples of anaerobic treatment systems.

Utilizing Dairy Wastewater for Electricity

India is presently the world's biggest milk producer, with yearly production exceeding 100 million tonnes. Consumer milk, butter, cheese, yoghurt, condensed milk, milk powder, and ice cream are all made from raw milk. By-products such as buttermilk, whey, and derivatives are common. The dairy business, on the other hand, generates a significant amount of effluent - more than twice the amount of milk processed. This wastewater pollutes the environment. Because it includes nutrients for bacterial growth, it poses a risk to the environment. However, microbial fuel cells can be employed to create power.

Conclusion

The cleaning and washing operations in the milk processing plant generate dairy wastewaters. Dairy wastewater contains lipids, nutrients, glucoses, methanol, lactose, sucrose, and detergents, and has significant BOD, COD, and TDS concentrations.

Dairy wastewater discharge has major environmental consequences!

It lessens the demand for fossil fuels such as coal, oil, and gas. With the depletion of non-renewable energy resources, the demand for alternative eco-friendly fuel is fast growing.

Netsol Water are developing technologies that are renewable and can turn organic matter into electricity using microorganisms found in dairy effluent while also cleaning the dairy wastewater.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.