What is Sedimentation tank in waste water treatment plant?

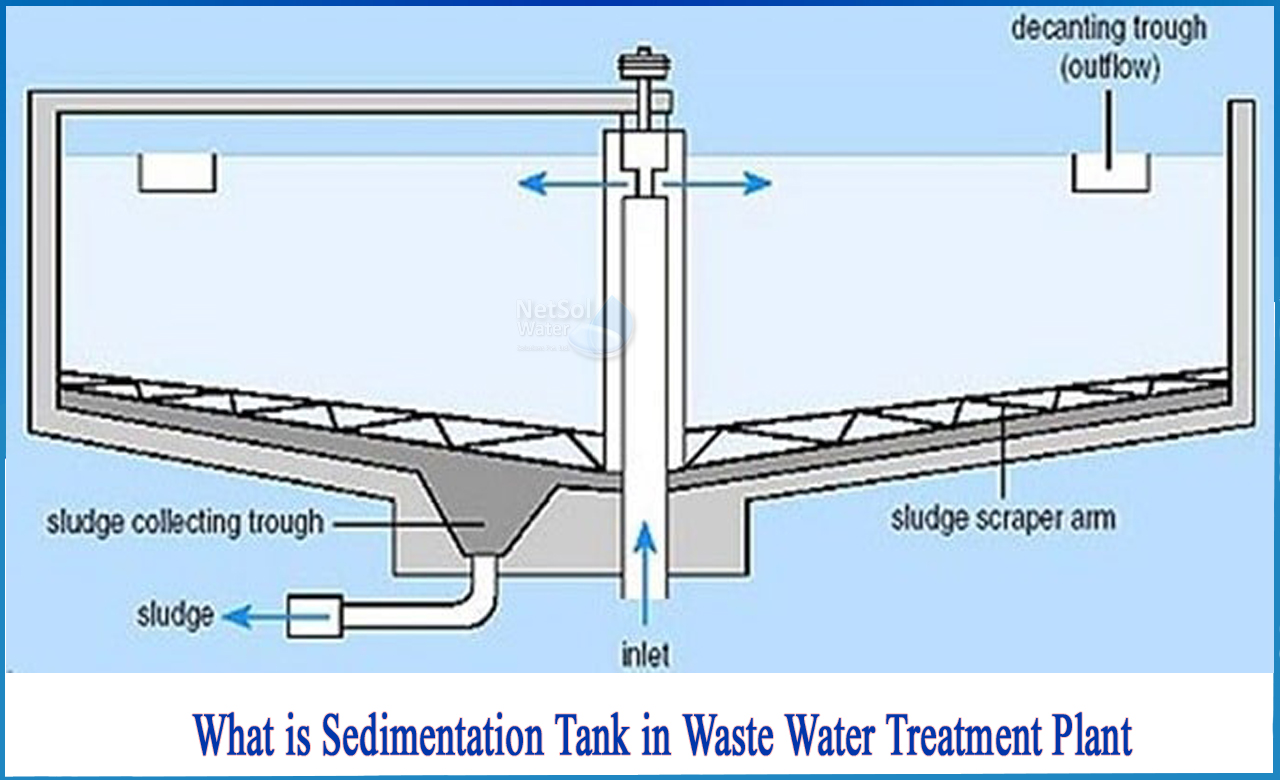

Sedimentation tank, also recognised as a settling tank or clarifier, is a component of a modern water supply or wastewater treatment system. A sedimentation tank enables suspended particles in water or wastewater to settle out as it flows slowly through the tank, providing some level of purification. At the bottom of the tank, a layer of accumulated solids known as sludge forms and is eliminated. Coagulants are added to the water prior to sedimentation to aid in the settling process, which is then followed by filtration and other treatment steps in drinking-water treatment.

To increase purification efficiencies, primary sedimentation must be followed by secondary treatment (e.g., trickling filter or activated sludge) in modern sewage treatment. Treatment with bar screens and grit chambers is usually performed prior to sedimentation to eliminate large objects and coarse solids.

Types of sedimentation tank

1. Rectangular Tanks:

Rectangular tanks are rectangular in plan and have a large number of baffle walls. The baffle wall's function is to prevent short-circuiting and to reduce the velocity of incoming water, thereby increasing the effective length of travel of the particle. This type of sedimentation tank is generally provided with channel type inlet and outlet extending across the entire width, and the floor between two baffles is made to look like a hopper sloping towards the centre where sludge-pipe is provided.

2. Circular Tanks:

There are 2 types of circular sedimentation tankson the basis of the flow of water:

- Radial Flow Circular Tank:Water enters this tank through the central inlet pipe located inside the deflector box, and the deflector box deflects the water downwards. The water then flows radially from the deflector box, where an outlet is provided on the entire periphery, through the holes provided in the bottom sides of the deflector box, towards the circumference of the tank.

- Circumferential Flow Circular Tank:Water enters the tank through two or three vertical slits, and one rotating arm moves water around the tank's circumference. To allow suspended impurities to settle in the tank water, which moves at a very low velocity and can be eliminated from the sludge outlet.

3. Hopper Bottom Tanks:

Water flows upward and downward in these tanks, which are vertical flow tanks. Suspended particles with specific gravity greater than one cannot follow the water when it reverses direction and settle at the bottom, where they are removed under hydrostatic pressure through the sludge outlet pipe. Rows of decanting channels are provided at the top to collect clear water, and water is taken out from the outlet channel provided on one side of the tank after flowing in the channel. These tanks are mostly used in sedimentation with the co-angulation process.

4. Fill & Draw Sedimentation Tank:

In this type, water out from inlet is stored for a period of time, possibly 24 hours, and the suspended particles settle at the bottom of the tank during that time. After 24 hours, the water is discharged through the outlet. The settled particles are then removed, which takes 6 to 12 hours, so in the case of a fill and draw-type sedimentation tank, one complete sedimentation action takes 30 to 40 hours.

5. Continuous Flow Tank:

In this case, the water is not allowed to rest, and flow occurs at a very low velocity. During this flow, the suspended particles settle at the bottom of the tank, which can be vertical or horizontal.

Benefits of sedimentation tank

These tanks have the following benefits:

1. It is a low-cost and simple water pre-treatment technology.

2. It has low operating costs and can handle a variety of flows.

3. Coagulants shorten the time required to settle out suspended solids.

4. It has a high clarification efficiency and is simple to remove sludge from.

5. It is best suited for plants with consistent flow rates and quality.

6. Natural coagulants can sometimes be obtained for free or at a low cost.

For more information, contact Netsol Water!

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.