Reusing treated sewage water is essential in metropolitan areas with scarce freshwater sources. In fact, using treated sewage water for flushing, gardening, and cooling towers is required in the majority of commercial facilities. The quality of treated water is assumed to be very good when any sewage-treated waste water is being reclaimed for non-potable use. It should be devoid of microorganisms, colour, and odour. Ozone technology hence becomes most effective & efficient in this case, where high quality of STP treated water is desired.

In this article, we will understand about the ozonator system in sewage treatment plants, as well as how it helps to kill bacteria.

Treatment of sewage water

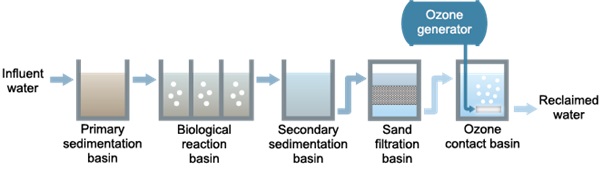

In order to treat home, commercial, institutional, and industrial sewage water, all sewage treatment plants use primary, secondary, and tertiary treatment stages. The secondary stage of treatment is the key step in making sewage water safe, for the environment by allowing different varieties of bacteria to break down contaminants, primarily human faeces. Following the biological secondary stage, the primary functions of the third stage are disinfection, or the eradication of the bacteria's ability to spread.

Chlorine is utilized in the third or tertiary stage of disinfection in the majority of sewage treatment systems. Chlorine usage in STP is outlawed in many nations and by pollution control organisations, because to several environmental risks. Therefore, ozone is utilised as a tertiary treatment to kill microorganisms all around the world. In fact, many scientists, environmentalists, and pollution control agencies highly advise using ozone in the tertiary stage of sewage treatment plants.

What is ozonator in sewage treatment plants?

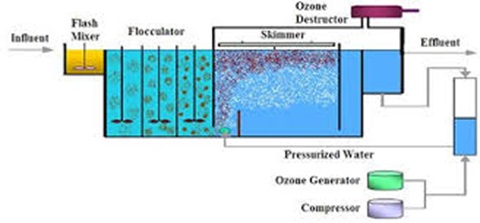

An ozonator is a mechanism or equipment that treats or purifies water using ozone or O3. Ozonators are used alone or in conjunction with reverse osmosis or UV water filtration systems to purify sewage water.

Use of ozone for sewage treatment

In the process of treating water, ozone is utilised to filter out undesirable components. Some of the crucial jobs that ozone performs include:

1. Ozone fully kills biological organisms in sewage, including fungi, by rupturing their cells.

2. It alters the taste of the water while treating potable water. The taste of water is worsened by excess ions like salt and potassium. To improve the taste of the water, these ions must be eliminated. These ions are quickly removed by ozone.

3. It neutralises fertilisers. These are employed in both agriculture and industry. Water becomes harmful when these fertilisers are added to it. Ozone is an extremely effective fertiliser neutralizer. It renders fertilisers harmless by breaking them down. Industries also frequently utilise water softeners and ozonators together.

Components of ozonator used in Sewage treatment plants

Ozonator parts include:

· Transformer

· High-voltage electrode

· Insulating substance

· Low voltage electrode

Use of ozonator in the existing sewage treatment plants

Ozonation can be implemented into the current sewage treatment system's tertiary stage, without requiring any changes. The use of a regular chlorine contact tank as an ozone dosing, mixing, and contact tank is possible.

It clarifies water and eliminates heavy contaminants that have been dissolved in it. It generates ozone gas (O3), which kills microorganisms 50 times faster than any other water treatment method.

How does an ozonator help to kill the bacteria in STPs?

An ozonator has a strong electrical field. When dry air or oxygen passes through this intense electrical field, the oxygen molecules (O2) split into two single molecules (O), which then immediately combines with additional oxygen molecules (O2) to form ozone (O3). This oxygen decomposes heavy chemicals, fertilisers, biomaterials, bacteria, viruses, etc. when combined with sewage water.

Use of ozonator in the new sewage treatment plants

For the best possible performance in the event of new STP construction with an integrated Ozone System [IOS] for tertiary sewage treatment, it is possible to lower the size of the clarified water tank to 1.5 to 2.0 times peak flow. To lessen the burden on ozone dosing, secondary clarified water must first be filtered before going through the ozonation process.

All non-potable uses, such as flushing, gardening, surface cleaning, cooling towers, and industrial use, can be made with the use of the final ozone-treated water.

Disadvantages of ozonator systems

Ozonator provides a lot of benefits, but it also has some drawbacks:

1. It may be cancerous: If there is bromide in the sewage water, then the danger of cancer from bromide and ozone combined is very high. Thus, it is crucial that we determine whether or not there is bromide before installing an ozonator.

2. It requires high power consumption: Ozone cannot be stored and must be created on-site. As a result, ozone generator uses a lot of electricity.

3. It produces by-products: Although, using an ozonator or ozone renders biological, chemical, and physical contaminants harmless, it also creates by-products.

4. It may cause reinfection: The main negative impact of the ozonator is reinfection. In ozonator-treated water, there is always a chance of reinfection. It is acceptable to consume ozonator-treated water right away or to put it in a bottle. However, if we supply it from a distance via a canal or pipeline, the water becomes re-infected.

Conclusion

Nowadays, ozonators are highly sought due to increased industrialization. The Government of India has established regulations prohibiting the direct drainage of chemically contaminated water. Therefore, having a disinfection unit is required for industries. Since, no chemicals or powders are used by the ozonator to purify the sewage, ozone-treated water is safe.

High quality water treatment plants from Netsol

Clean water is produced by Netsol Water water treatment systems, which are designed, built, and installed with safety and the environment in mind. Our various sewage disinfection systems can be constructed according to the needs of the customer.

These systems are also certified. We also encourage our clients to talk to us about the high-quality, pure water they need. Call us at +91 9650608473 or email at enquiry@netsolwater.com for further information.