What is Microbubble filtration in Wastewater Treatment?

Microbubble technology has gotten a lot of press because of its wide range of applications in science and technology, such as water purification, biomedical engineering, and Nanomaterials. Microbubbles have considerable potential for large-scale application in water and wastewater treatment due to their propensity to create free radicals, and so should be a primary focus of study and process development.

This type of flotation is commonly utilized in the purification of water. In reality, because it includes hydroxide and/or organic compounds, this flotation is well-suited to the treatment of floc that is typically fragile and has a low density.

In DAF, pressurization is used to create microbubbles!

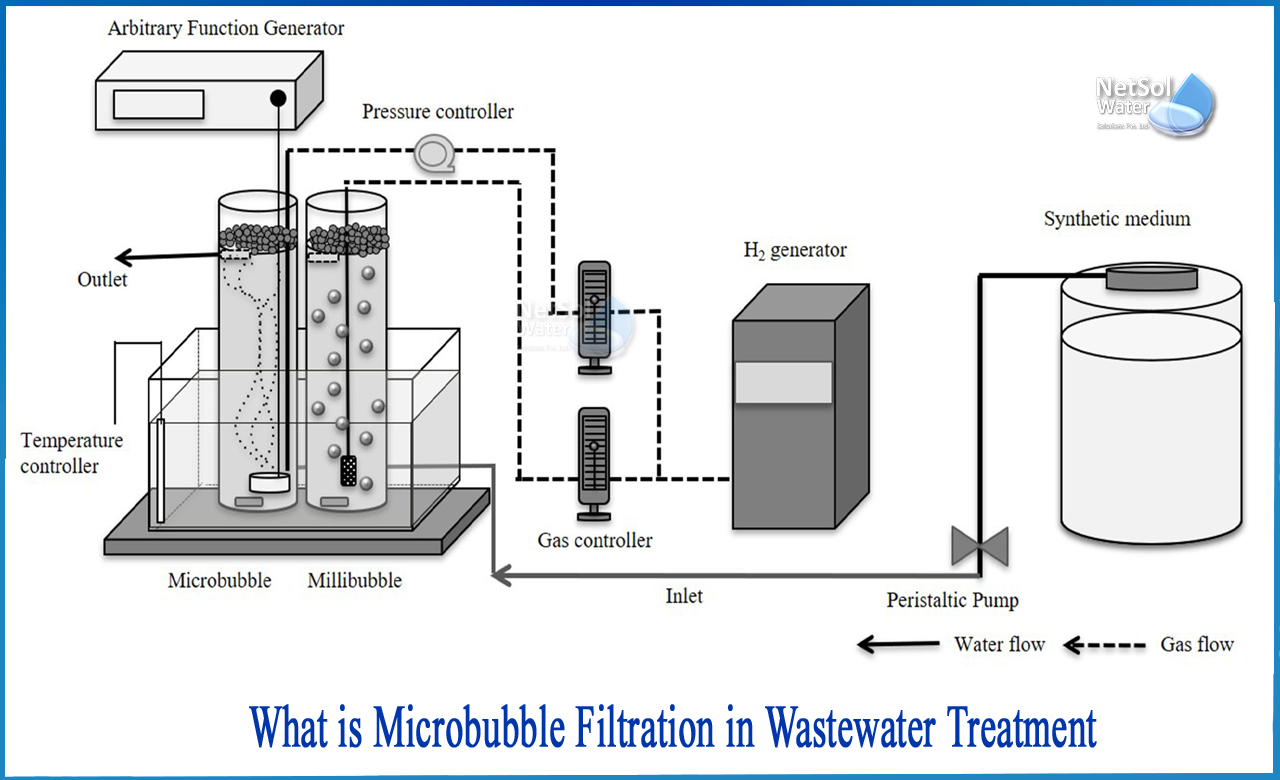

The most common method for producing microbubbles is by pressurization. In a vessel called a gas saturation tank, wastewater is brought into contact with gas (air, nitrogen, or natural gas) at a pressure of a few bar, or a pump for gas dissolution in wastewater.

The pressurized liquid can be all or a portion of the raw water flow (direct pressurization) or a percentage of the recycled treated water.

Indirect pressurization is employed in the clarifying treatment of surface water or inland wastewater. The pressurized water flow accounts for 5 to 50% of the throughput to be treated at pressures of 4 to 6 bars. In actuality, gas dissolves at a rate of 70 to 95 percent of saturation at the pressure in question, and compressed gas consumption varies greatly from one application to the next.

Note:It's worth noting that a single 2 mm diameter bubble will use the same amount of air as 20m diameter bubbles. Furthermore, the size of the bubble will cause turbulence, jeopardizing the successful mixing of "white" water (bubble stream) with flocculated water.

All DAF flotation units come with the following features-

1: A flocculation zone upstream;

2: Immediately after the microbubbles appear, a floc and depressurized water mixing zone;

3: A floating chamber with a larger surface area than the cake scraped or hydraulically removed from (by overflow);

4: Finally, an overflow zone where treated water is retrieved.

These zones are arranged in a logical order and can be arranged in a variety of ways.It should be noted that floatation of all suspended materials is not always achievable with wastewater. Because part of the floating stuff is too heavy, it will inevitably gather along the unit's floor. In addition, all flotation units that handle IWW, or sludge have a method for eliminating bottom sludge (a floor that is very conical or bottom scrapers).

In the realm of water treatment, DAF has a wide range of applications-

1: Filtering out flocculated matter in stilling surface water clarifying applications that are heavy in OM, algae, and/or have a lot of colour;

2: Extracting and recovering fibers from paper mill water, as well as proteins and fats in the food industry;

3: Oil separation from wastewater generated by refineries, airports, and metallurgical plants;

4: Metal hydroxides or pigments are separated;

5: Used instead of a clarifier for clarifying activated sludge liquor (a rather unusual situation);

6: Physical-chemical therapy at the tertiary level;

7: Excess sludge from wastewater biological treatment or clarifying treatment in drinking water applications (including filter and bio-filter washing sludge) is thickened.

Technical assistance and guidance

Netsol Water collaborates with a wide range of international organizations to tackle complicated problems by strategically integrating modern treatment technology with practical solutions. We can also provide a good framework of WWT plant along with various filtration units, among other services.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.