How to design MBBR Media?

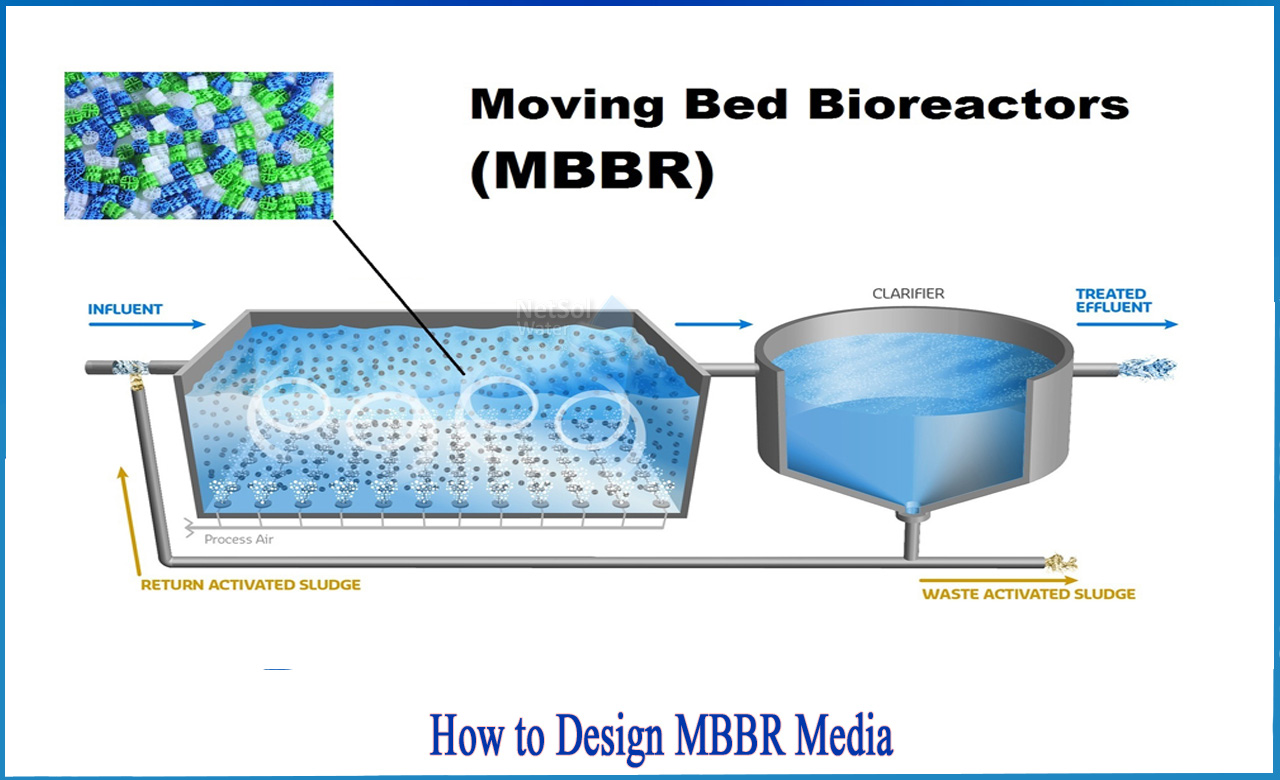

MBBR was invented in the 1980s.Its full form goes like “Moving Bed Biofilm reactor”. MBBR provides an economical solution for wastewater treatment. MBBR is a highly effective biological cleaning process based on a combination of traditional activated sludge process and biofilm medium.

The MBBR process uses large volumes of microorganism floating media in aeration and anoxic tanks. Microorganisms consume organic matter. The medium provides an increased surface area for biological microorganisms to attach and grow. Increasing the surface area reduces the space required for the tank to treat the wastewater. The processing process is aerobic or anaerobic and works with heavy loads.

STP MBBR technology is the use of mobile bed biofilm reactors in sewage treatment facilities. MBBR system design is used in combination with activated sludge processes.

It uses the capacity of the entire tank for biomass growth by mounting a carrier for accretion growth of biofilm. The agitation of bubbles allows the carrier to move. The reactor can take any shape and can carry different loads depending on the carrier filling.

The MBBR design of the reactor depends on the characteristics and location of the actual wastewater. The system optionally comes with a rectangular sieve mounted vertically or horizontally. The reactor can also be equipped with a cylindrical rod screen. The MBBR beam is a cylinder with a cross on the inside and ribs on the outside to increase the surface area.

Operation and maintenance of MBBR:

For continuous use, MBBR does not require backwashing or sludge return. Due to the aeration of course, air bubbles in the aeration zone, the operation of the wastewater treatment tank is inexpensive. Stirring constantly moves the carrier throughout the service and prevents clogging.

Benefits of MBBR Small compact unit:

>Improvement of therapeutic ability

>Complete removal of solids

>Improved sedimentation characteristics

>Operation with higher floating biomass

>Concentration that increases sludge retention time

>Improved process stability

>Low pressure loss

>No filter channelling

>No regular backwash required

>Reduces sludge generation and has no problem with sludge replenishment

MBBR mechanism

The MBBR process uses suspended plastic carriers (mediums) in activated sludge tanks to increase the amount of microorganisms available to treat wastewater. Microorganisms eat organic matter. This medium increases the surface area for biological microorganisms to attach to and grow in the aeration tank.

Increasing the surface area reduces the space required for the tank to treat the wastewater. The medium moves continuously by air bubbles from the aeration system, adding oxygen to the bottom of the first chamber of the aeration tank. It offers superior efficiency and value compared to traditional secondary processing.

MBBR system is primarily in the form of sieving, sludge treatment and inflow balancing, including maintenance of the integrated control system and sewage treatment plant. MBBR requires skilled personnel to regularly monitor the operation of pumps and blowers. MBBR technology has a mechanism to maintain biofilm levels.

Design of MBBR media

Let us take an example to better understand the MBBR Media design:

Question: A waste water flow of 1 MGD (Million gallons per day) containing 100 mg/L BOD is to be treated in MBBR reactor?

AssumingRemoval efficiency of 90-95%, therefore,

Design SALR (Surface Area Loading Rate) value= 7.5g/m2 /day

BOD loading rate = 1MGD *100 (Mg/L) *8.3 (Lb/mg/MG/L) =830 (lb/day)

= 830 (lb/day) *453.59 (g/lb)

=376479.7 g BOD/day

Required Surface area = (376479.7 g BOD/day)/7.5g/m2 /day = 50197.2 m2

For more information, contact Netsol Water.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.