What is Gravity thickening of bio solids?

Thickening is the process by which bio solidsare condensed to produce a concentrated solids product and a relatively solidfree supernatant.

Thickening wastewater solids reduces the volume of sludge, improves operation, and reduces costs for subsequent storage, processing, transfer, end use, and disposal. For example, thickening liquid solids (slurry) from 3 to 6 percent will reduce the volume of waste by 50 percent.

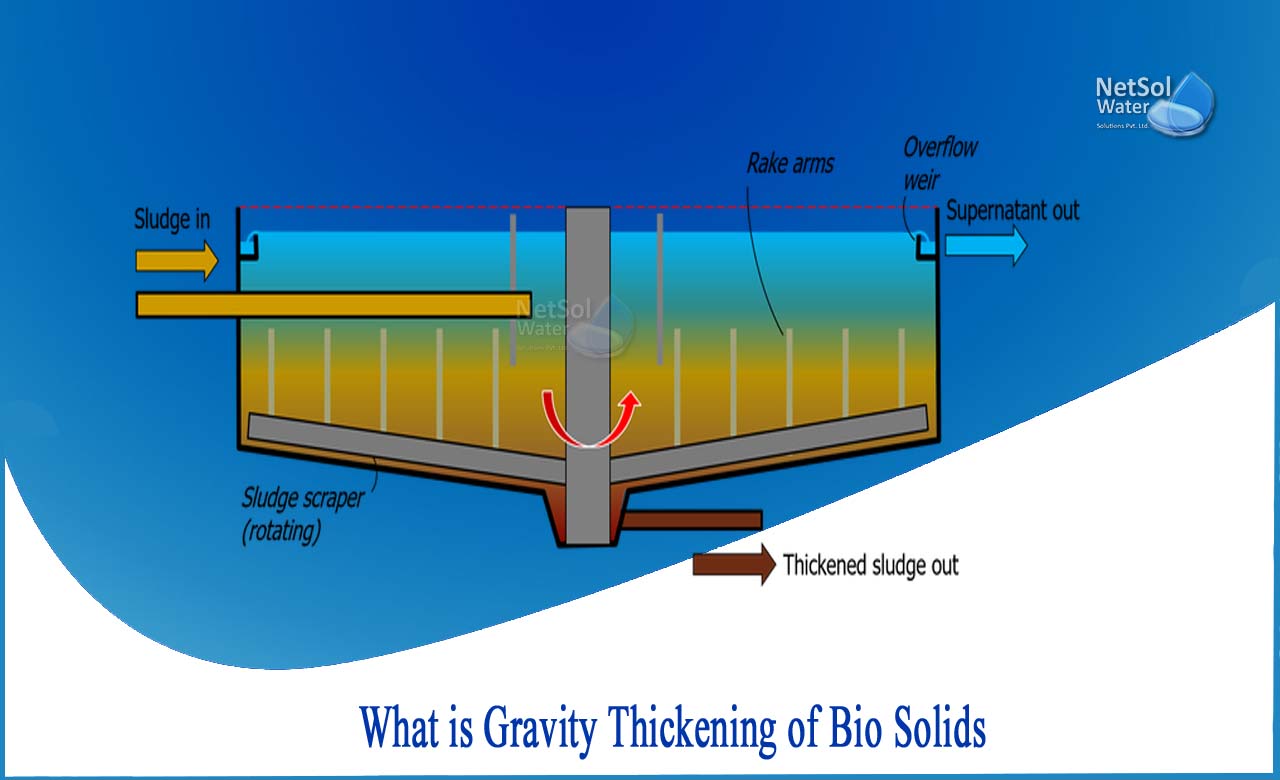

Gravity thickening uses the natural tendency of molecules of higherdensity solids to settle out of liquids to concentrate the solids. Gravity thickener consists of a round container (usually with a conical bottom), collector or scraper at the bottom.

Primary or Secondary solids

The centreof the tank often releases solids’ low velocity near the tank surface. Solids settles on the bottom of the tank, and the scraper slowly moves the settled thick solids.

Many systems also use skimmers for collection which removes any suspended matter and grease that is present and accumulates it at the top of the tank. The bio solids concentration and thickening that occurs in the tank is achieved through three different settling processes viz.gravity settling, hindered settling, and compaction settling.

1-Gravity settling occurs when solid particles travel downwards due to their weight.

2-Settlement continues as solids begin to concentrate at the bottom of the tank, but the settlement rate decreases as the solid concentrations increases which is known as “hindered settling.”

3-Compaction settling occurs when bottom solids are further concentrated due to the pressure of solids on top of them. Solids at the bottom of the tank can reach as high as 15 percent total solids of the total volume.

Quite typical result

Dry matter is 4 to 6 percent of the surface liquid. The tank contains suspended solids andis almost transparent.

Transition

A point between a clear liquid and a thick solid is called the point of transition while a thick layer of solid develops in that tank called "A solid blanket."

Conclusion

Solid thickening can prove to be beneficial as it is one of the bestin sewage treatment facility. Thickening technology options including gravity thickening, DAF, centrifugal thickening and gravity thickening of the belt.

All these technologies are commonly used, but with different performance criteria such as achieved solid content concentration, separation of solids, odours, energy requirements, work requirements, sensitivity to temperature changes, and solid properties. In addition, pilot testing should be performed before designing the system.

Evaluation of gravity thickening as an option should include evaluation of the solids as discussed below.

1: Primary solids are easily thickened using gravity than are secondary solids.

2: Primary solids settle quickly and form a thick solids layer.

3: The settled solids can be pumped out of the tank and do not require the addition of extra chemicals for thickening.

4: Many field and laboratory tests show that the first waste should be activated. Solids, including primary solids, can help settling increase the residence time before processing.

The solids begin to generate gas and rise to the surface. The potential drawback of this practice is bio solidodourin some plants as there is greaterodour when primary waste is activated. The solid matter is thickened at the same time.

Unlike primary solids, secondary solids require large surface area per unit mass, low settlement rate and resistance to compression. As a rule, only gravity thickening is used.

The required thickening cannot be achieved only by gravity thickeners. For this reason, Gravity thickening usually involves several other thickening methods for secondary solids which is a biological process. Gravity thickening reduces the downstream requirements for further sludge processing, and thus it is often used prior to anaerobic digestion or lime stabilization.

How can Netsol Water help?

Netsol is India’s leading wastewater and water treatment solution company which covers all the needs of any water treatment scheme on all levels. We have the expertise to provide waste water solutions at domestic, industrial and municipal level.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.