How to commission or plan a Common Effluent Treatment Plant?

In order to minimize deficits, the establishment of a CETP necessitates careful preparation!

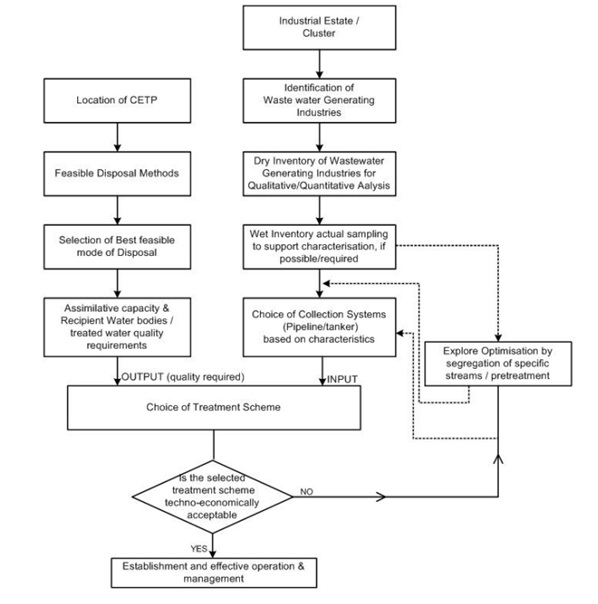

Following is a flowchart of the stages involved in planning or commissioning a CETP-

Following are some of the factors that impact the effective planning and operation of CETPs

1: The treatability of mixed effluent streams generated by diverse types of enterprises is a challenging problem in terms of developing a treatment system and implementing it.

2: Categorization of CETPs: CETPs are categorised depending on the mix of industries that they serve, such as those that serve homogeneous industries (all member industries are in the same industrial sector and perform comparable activities) and those that serve heterogeneous industries (those who serve a variety of sectors).

While quantitative and qualitative variations in homogeneous industries may be anticipated owing to identical processes, heterogeneous industries require greater flexibility in treatment units to accommodate a wider range of such fluctuations.

As a result, a full inventory of the member industries is a critical first step in building a CETP to identify the types of activities and probable effluent constituents.

3: Emerging treatment methods and treatment combinations offer the ability to handle a diverse spectrum of pollutants at increasing concentrations.

As a result, CETP inlet criteria must be determined using planned inlet concentrations.

Rather of attempting to regulate numerous distinct member sectors, upgrading centralized treatment facilities for extra-specialized pollutants, such as ammonia nitrogen treatment, is frequently a sensible choice

4: Effluent qualitative/quantitative fluctuations: Quantitative fluctuations indicate the volume of the equalization tank. Furthermore, the modular design of an effluent treatment plant (ETP) is critical for the effective management of variable hydraulic loads (frequent product changes-corresponding hydraulic loads, etc.). To homogenize the influent characteristics or avoid shock loads, qualitative variations specify/correct the capacity of holding/equalization tanks.

5: Waste minimization: Waste minimization is an essential part of waste management. In other words, rather than attempting to address trash as it is generated, maximal effort may be made to avoid, minimize, and/or use byproducts.

6: Pre-treatment requirements: Initially, CETPs were merely sinks of raw effluents from industries, and they suffered from a lack of discipline in pre-treatment at the industries, as well as a scientific understanding of the complex characteristics of collection, segregation, and corresponding treatability studies of waste streams, particularly where a wide range of products were manufactured in member industries.

7: Effluent stream segregation at particular member industries: Effluent streams might be broadly separated for correctly mixing depending on their appropriateness for a given treatment solution.

8: Collecting and monitoring method: This mechanism, in addition to facilitating plant operations, plays a vital part in the cost-effectiveness of the treatment.

9: Treatability, technology selection, and biodegradability, interferences:Treatability of studies aids in the characterisation of physical, chemical, and biological waste, and therefore aids in the selection of the best treatments.

10: Disposal mode:The following are the disposal modes for treated effluents from a CETPs:

- Surface bodies of water;

- Irrigated land;

- Outfall from the sea;

- Sewerage System (Public).

11: Fee structure:Treatment expenses would comprise regular collection as well as treatment fees.

What do we have to offer?

You've come to the correct spot if you want to learn more about typical effluent treatment plants!

You can have an expert solution upon contacting Netsol Water, a leading manufacturer of Industrial and Commercial Water and Wastewater treatment plants, among other services. Our wastewater treatment systems are very effective at removing all types of chemical, physical, and biological pollutants.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.