What Is Electrodeionization (EDI)?

Electrodeionization (EDI) describes a water purification process that removes charged particles from water. This method uses electricity and specialized resins to produce water with very low conductivity. Industries that demand ultra-pure water depend on EDI to meet strict quality requirements. Netsol Water integrates EDI into its systems to deliver consistent performance and high purity. Understanding electrodeionization helps businesses choose the right technology for their water treatment needs.

Understanding Electrodeionization (EDI) Technology

Before exploring application details, we first consider the core function of EDI. This process drives ions through ion exchange membranes. It uses an electric field instead of chemical regenerants. Let us have a look on some key aspects of this technology.

Electric Field and Ion Exchange

Electrodeionization depends on a direct current field that moves charged particles. Cation exchange resins let positive ions travel toward the negative electrode. Anion exchange resins guide negative ions toward the positive electrode. This movement prevents ions from staying in the water stream. The electric current regenerates the resins continuously. This eliminates the need for chemical cleaning.

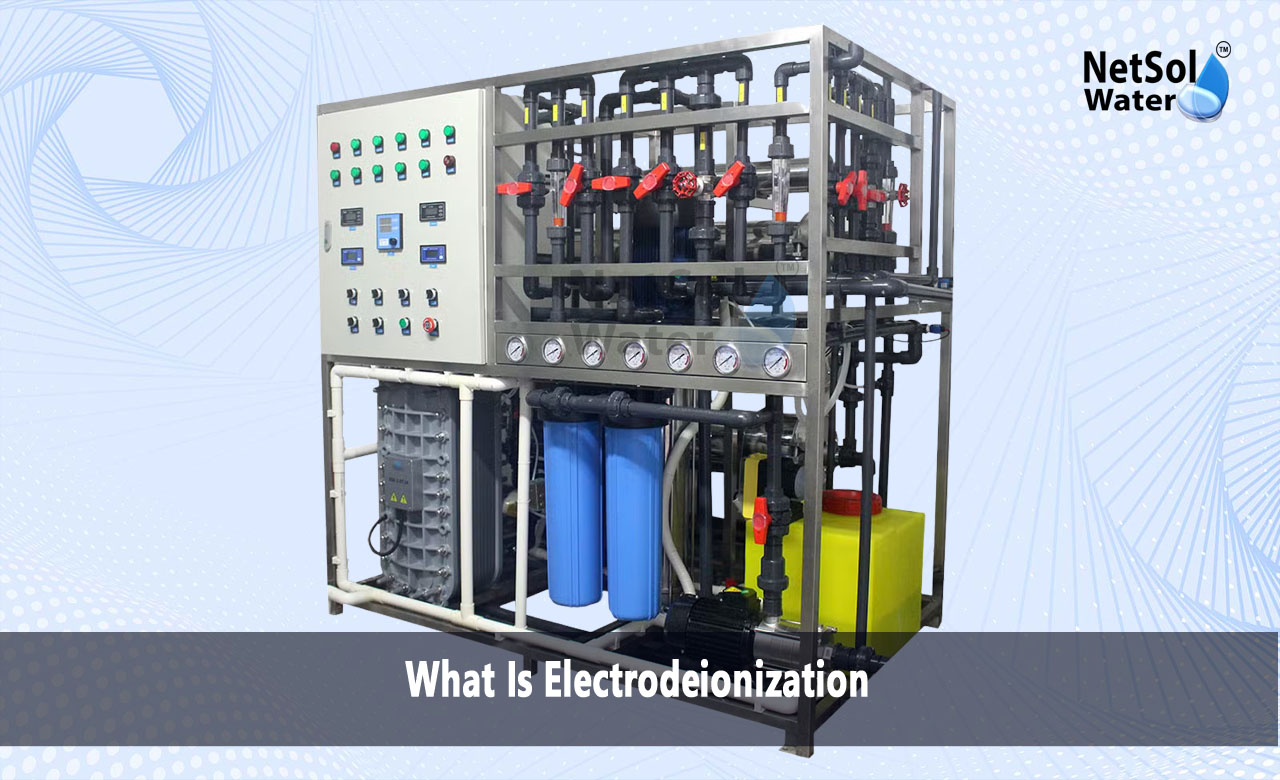

Membrane Arrangement in EDI Modules

EDI modules contain alternating layers of cation and anion membranes separated by resin chambers. The membranes create selective pathways. They permit ions to cross in one direction. The resin beds capture ions and release them when the field changes. This arrangement yields a continuous cycle of purification and regeneration.

Benefits of Electrodeionization with Netsol Water

Recognizing the benefits of EDI helps explain why many industries trust this approach. Netsol Water enhances each advantage through custom design and ongoing support. Let us have a look on some ways EDI delivers value.

Continuous Production without Chemicals

Electrodeionization runs without adding acid or caustic. It keeps the system clean using only electricity and water. Netsol Water configures each EDI skid to match customer flow rates. This design ensures steady delivery of pure water at scale.

Low Operating Cost and Footprint

EDI units occupy less space compared with conventional deionization systems. They require no chemical storage or handling areas. Netsol Water optimizes layout to fit existing plant footprints. This approach reduces installation cost and eases maintenance.

High Purity and Consistency

Electrodeionization achieves resistivity levels above 16 megohm-centimeter. This quality meets the needs of electronics manufacturing and pharmaceutical production. Netsol Water monitors system performance 24/7. It alerts operators immediately if any parameter drifts.

Applications of Electrodeionization (EDI)

Electrodeionization adapts to many water treatment scenarios. Netsol Water integrates EDI into complete treatment trains. Let us have a look on some industries and uses that benefit from this technology.

Power Generation Plants

Turbine feedwater quality affects plant efficiency and steam purity. Electrodeionization polishes boiler feed water. It prevents scaling and corrosion without interrupting operations. Netsol Water collaborates with plant engineers to size each EDI system correctly.

Semiconductor Manufacturing

Semiconductor wafers require water free of ionic contaminants. Electrodeionization removes trace ions that damage circuits. Netsol Water supports cleanroom requirements with redundant EDI trains. This redundancy ensures no downtime during maintenance.

Pharmaceutical and Biotechnology

Pharmaceutical processes demand water that meets USP standards. EDI delivers water within tight conductivity ranges. Netsol Water handles validation documentation and on?site qualification. This service helps customers pass regulatory audits smoothly.

Integration with Existing Water Treatment Systems

Many facilities combine EDI with reverse osmosis and filtration. This layered approach improves overall efficiency.

Pre?Treatment Compatibility

Reverse osmosis removes bulk contaminants before EDI. Softening and carbon filters protect membranes and resins. Netsol Water engineers design each pre?treatment stage for long term reliability.

Automation and Control

Advanced control panels track flow, pressure and conductivity. Automated alarms prompt preventive measures. Netsol Water programs each controller to deliver intuitive operation. Operators adjust setpoints easily through a touchscreen interface.

Maintenance and Service Support

Routine checks sustain performance over years of operation. Netsol Water offers preventive maintenance plans. Technicians replace membranes and resins at scheduled intervals. Custom spare parts kits arrive promptly when needed.

Conclusion

Electrodeionization (EDI) offers a powerful path to ultra?pure water without using chemicals. Netsol Water brings expertise and tailored solutions for industries that require the highest quality water. To learn more about electrodeionization (EDI) or to discuss your project needs get in touch with our team today. We look forward to helping you achieve consistent ultra?pure water for your operations.

Contact Netsol Water at:

Phone: +91-9650608473, Email: enquiry@netsolwater.com