Heavy-metal treatment in industrial wastewater is critical for protecting human health and the environment. Current heavy-metal treatment methods have numerous limitations.

Because, of their high cost and limited removal efficiency, common methods cannot meet the needs of actual production, for large quantities of industrial wastewater. In recent years, electrochemical deposition has been a rapidly developing clean treatment technology.

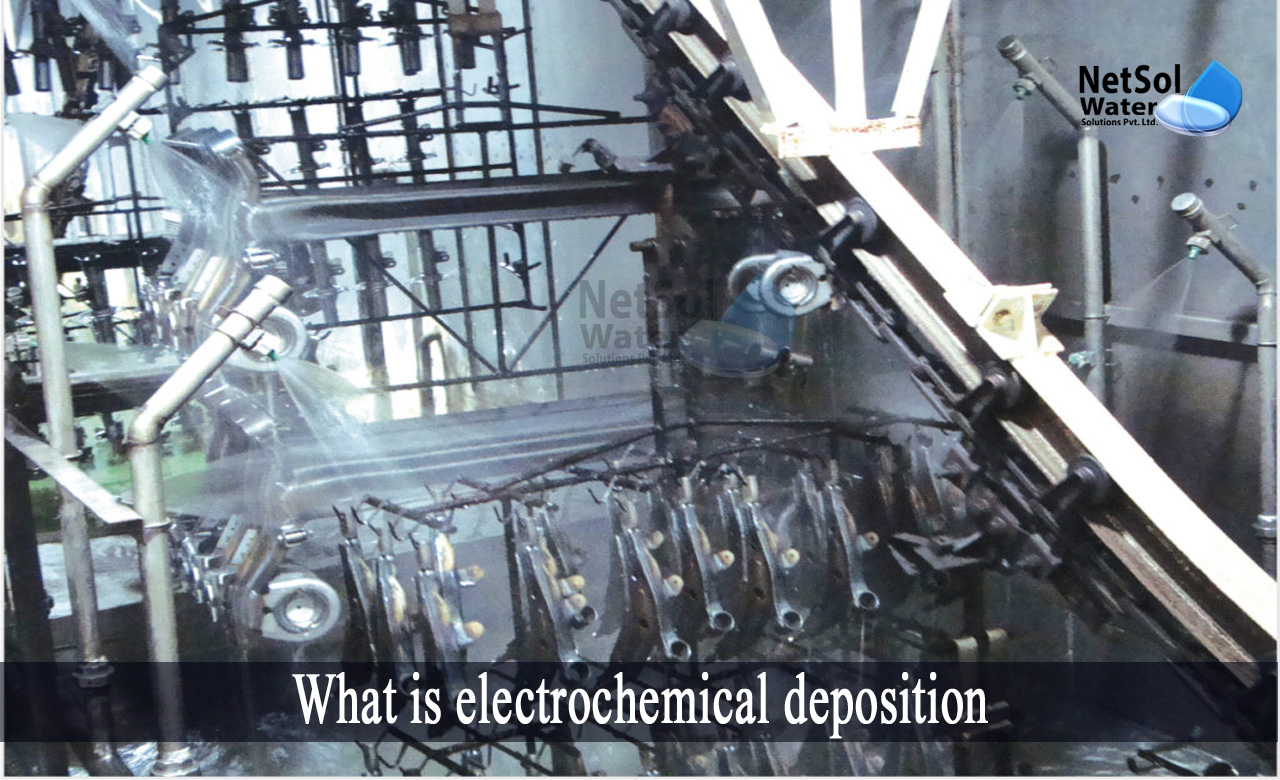

Let’s understand how heavy metals are removed from wastewater, using electrochemical deposition!

Electrochemical technologies in Wastewater Treatment

The most important factors in electrochemical processes are potential, current density, current efficiency, and CE (i.e., how much current is consumed to produce a certain product vs total consumption).

For metal recovery, the performance of electrochemical reactors is defined by the space-time yield of the reactor, which is the amount of product produced by the reactor volume in unit time.

Heavy metals can be recovered from wastewater streams using electrochemical deposition.

The main advantage of using electrochemical treatment is that no additional chemicals are introduced. Furthermore, heavy metal ions can be selectively removed via electrochemical treatment.

What is electrochemical deposition?

Electrochemical deposition is a method of depositing a thin and tightly adherent desired coating of metal, oxide, or salt, onto the surface of a conductor substrate through simple electrolysis of a solution, containing the desired metal ion or its chemical complex.

Process of electrochemical deposition

The process was developed based on the reduction of metallic ions from solution, and the oxidation of a compound from solution as a reducing agent, followed by film deposition as a result of the process's internal current.

It is an autocatalytic method that appears due to the presence of a metal cation, reduced by electrons presented onto the metal surface of a substrate, or a catalyst that is responsible for initiating the deposition process.

The following materials are used as templates and have transversal pores:

· Insulating materialssuch as alumina, and track-etched polymers such as polycarbonate (PCTE) and polyethylenterephtalate (PET).

· Gold or other metal deposition occurs on the entire surface of the membrane used as a template, including the inside walls of the pores, during the deposition process.

Advantages ofthe electrochemical deposition process in removing heavy metals

When compared to traditional techniques, the process has numerous advantages.

· The main advantages are that no additional chemicals are introduced into the wastewater prior to treatment, the process is simple, pollutants can be easily neutralized, and there is no secondary pollution.

· The equipment needed to operate the technology is simple and straightforward. The operation costs are low, and process automation is possible.

· Furthermore, because the smallest colloidal particles move faster under the applied electric field, they can be efficiently removed.

Conclusion

The electrochemical deposition method employs high energy electrons as a reductant, with a very small amount of chemical reagent. It is an excellent heavy metal wastewater treatment method, due to its ease of use, lack of secondary pollution, high removal efficiency, and quick reaction time.

How can we assist?

A wide variety of wastewater treatment options are offered by Netsol Water, including water treatment, wastewater treatment, sewage treatment, effluent treatment, along with advanced physical, chemical and biological methods of wastewater treatment.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.