What is Coagulation and Flocculation in Effluent Treatment?

Water pollution has turned into a huge worry lately, presenting serious dangers to the environment and human well-being. Industrial effluents, specifically, are a significant supporter of water pollution, containing different pollutants like suspended solids, organic matter, and heavy metals. To resolve this issue, appropriate treatment strategies are significant prior to releasing the effluents into water bodies. Among the different methods utilized, coagulation and flocculation have demonstrated to be exceptionally successful in eliminating contaminations from effluents.

What is Coagulation and Flocculation?

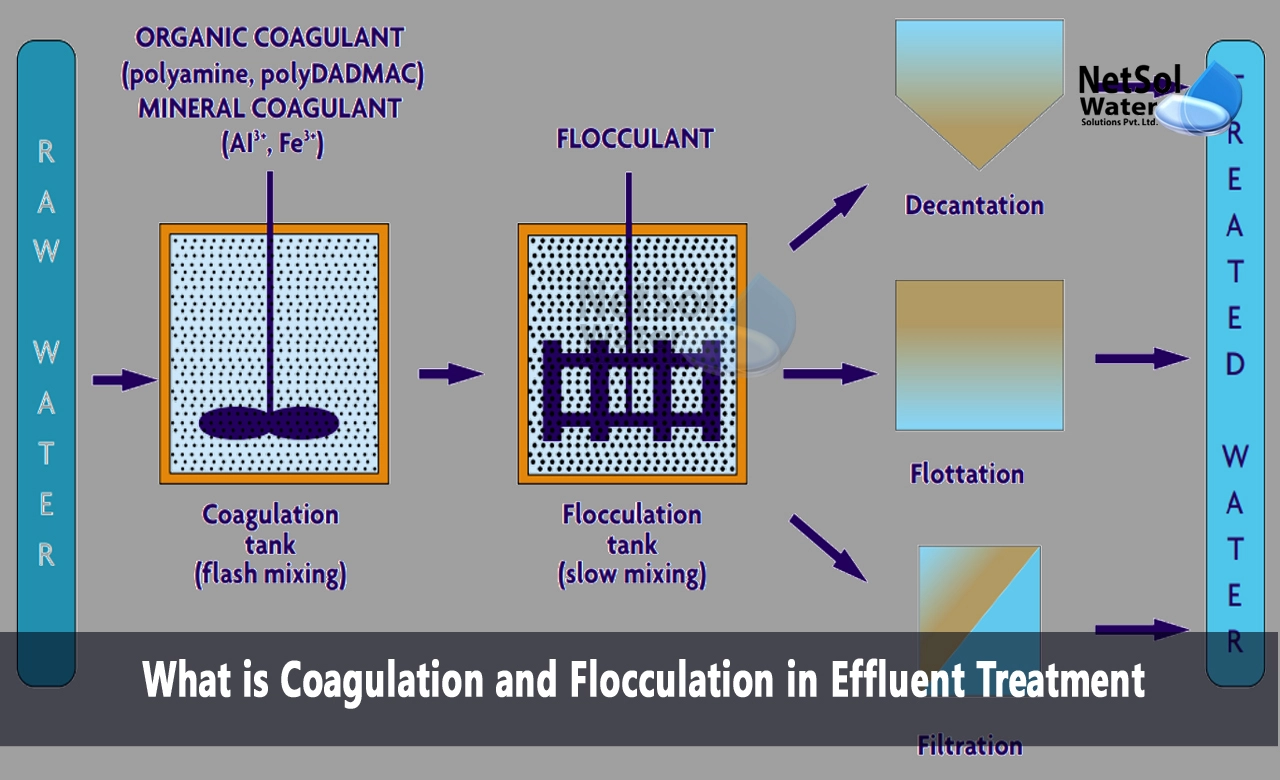

Coagulation and flocculation are two particular, yet firmly related processes commonly utilized in water and wastewater treatment. Coagulation includes the destabilization of colloidal particles by neutralizing their charges, permitting them to agglomerate and shape bigger particles called flocs. Flocculation, on the other hand, is the process of gentle blending that upgrades the arrangement and development of these flocs, making them sufficiently enormous to settle or be eliminated by resulting filtration processes.

The Role of Coagulants and Flocculants

Coagulants are chemical agents added to the effluent to start the coagulation interaction. Normal coagulants incorporate aluminum sulfate (alum), ferric chloride, and polyaluminum chloride. These coagulants convey positive charges that neutralize the negative charges on the colloidal particles, making them undermine and shape micro flocs.

Flocculants, often manufactured polymers or normal materials like starch or chitosan, are then added to work with the flocculation cycle. These polymers advance the agglomeration of microflocs into bigger, denser flocs by making spans between the particles, permitting more straightforward partition through sedimentation or filtration

Factors Impacting Coagulation and Flocculation

A few variables play an essential part in the viability of coagulation and flocculation processes:

1. pH: The pH of the effluent significantly impacts the charge attributes of the colloidal particles and the exhibition of the coagulants. Ideal pH ranges differ contingent upon the particular coagulant utilized and the idea of the profluent.

2. Coagulant and flocculant dose: Proper measurements of coagulants and flocculants are fundamental for productive evacuation of toxins. Deficient measurements might bring about fragmented coagulation and flocculation, while exorbitant doses can prompt restabilization of particles and expanded slop creation.

3. Mixing intensity and duration: Appropriate blending during coagulation and flocculation is pivotal for viable molecule destabilization and flocculation. Fast blending during coagulation followed by delicate fomentation during flocculation guarantees ideal circumstances for floc development.

4. Temperature: Temperature can influence the solvency and response energy of coagulants, as well as the consistency of the gushing, affecting the general treatment proficiency.

Applications in Effluent Treatment

Coagulation and flocculation processes are broadly utilized in different ventures to treat effluents before release or further treatment. A few normal applications include:

1. Textile industry: Removal of colors, suspended solids, and organic matter from material effluents.

2. Mash and paper industry: Treatment of effluents containing lignin, cellulose filaments, and other wood-determined compounds.

3. Metallurgical industry: Removal of heavy metals, suspended solids, and oils from metal getting done and plating effluents.

4. Food handling industry: Treatment of effluents containing organic matter, oils, and suspended solids.

Advantages and Benefits

Coagulation and flocculation offer a few benefits in effluent treatment:

1. Efficient removal of a huge number of contaminations, including suspended solids, organic matter, and heavy metals.

2. Cost-effective and relatively simple processes compared to advanced treatment methods.

3. Similarity with other treatment processes, like sedimentation, filtration, and organic treatment.

4. Decrease in sludge volume compared to conventional settling processes, leading to lower disposal costs.

Difficulties and Constraints

While coagulation and flocculation are successful treatment techniques, they are not without difficulties and restrictions:

1. Sludge management: The process generates sludge that requires proper handling, dewatering, and disposal.

2. Interference from complex effluent compositions: Certain effluents with high levels of dissolved organic matter or specific contaminants may require additional treatment steps or specialized coagulants and flocculants.

3. Operational challenges: Maintaining optimal process conditions, such as pH, coagulant dosage, and mixing intensity, can be challenging, especially with fluctuating effluent characteristics.

4. Potential environmental concerns: Some coagulants and flocculants may have environmental impacts if not properly handled and disposed of.

Conclusion:

Coagulation and flocculation are fundamental cycles in the treatment of effluents, offering a powerful and cost-proficient method for eliminating contaminations before release or further treatment. By killing charges and advancing the development of bigger flocs, these cycles work with the evacuation of suspended solids, organic matter, and heavy metals from different modern effluents.

While coagulation and flocculation have demonstrated their adequacy, it is significant to understand the variables affecting their exhibition and address the difficulties related with their execution. Continuous innovative work in coagulants, flocculants, and process improvement will additionally upgrade the efficiency and manageability of these treatment techniques, adding to a cleaner and better environment.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.