The presence of metals such as copper, nickel, zinc, cadmium, chromium, and cyanides in the wastewater, makes it highly toxic in nature. A variety of specialized treatment processes for heavy metal removal, prior to discharge into the environment have been developed.

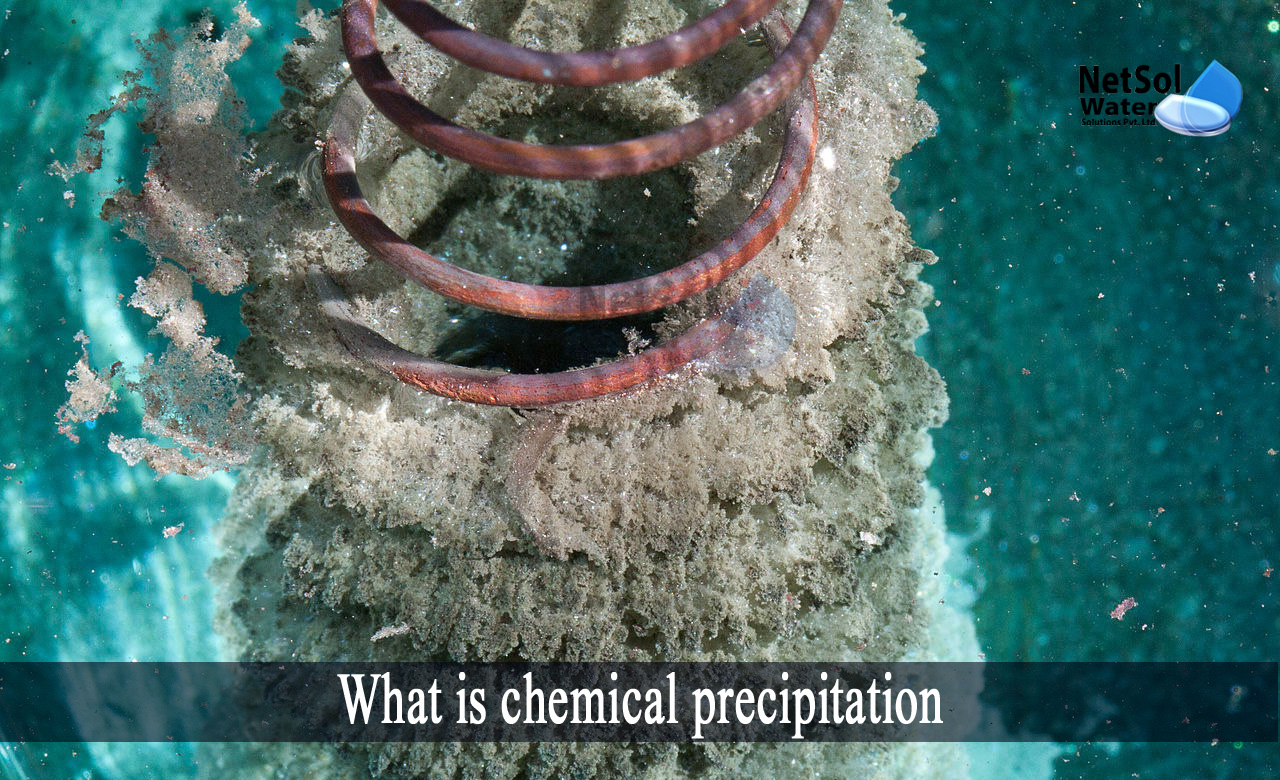

The simple chemical precipitation of metals as insoluble hydroxides, carbonates, or sulphides, is used to treat heavy-metal laden wastewater.

What is chemical precipitation?

Precipitation is the technique for removing dissolved heavy metals in conventional treatment. Heavy metal precipitation reduces the concentrations of all metals. The solubility of precipitated metal compounds is critical, to the success of this method. If a metal can form an insoluble compound, the compound can be removed via clarification and filtration.

Types of chemical precipitation

Hydroxide and sulphide precipitation are the two most common methods currently in use, with hydroxide precipitation being by far the most common. Because, of its low cost and simplicity, heavy metal hydroxide precipitation is the most commonly used treatment technique.

This process is as simple as raising the pH of the effluent with lime (CaO), caustic soda (NaOH), or magnesium oxide (MgO) as a precipitator, which immobilizes the heavy metals as their respective hydroxides. At low pH values, magnesium oxide is discovered to be an effective adsorbent, for eliminating heavy metal ions from aqueous solutions.

Process of chemical precipitation

Depending on the precipitant added to the wastewater, the precipitation can be done with hydroxide, carbonate, or sulphide.

The majority of acidic heavy metal waters are neutralized by adding alkaline solutions, which causes the heavy metals to precipitate as a hydroxide, i.e. they are bound to hydroxide ions. As precipitants, neutralizing agents such as caustic soda (sodium hydroxide), or lime (calcium hydroxide) are also used.

Sulphide precipitation for heavy metal removal

In acidic wastewater, partial heavy metal precipitation can be achieved by adding sulphide. Increasing the pH value, i.e. after neutralization, results in additional sulphide precipitation.

Precipitating and neutralizing agents must be added to the water for this purpose.Which type of precipitation should be used is determined by the residual metal content, in the water after precipitation. As with most chemical reactions, the precipitation process does not complete.

Even under ideal conditions, small amounts of the dissolved metal remains in the water, after precipitation.

Advantages of chemical precipitation for heavy metal removal

- Excellent separating power of heavy metals from wastewater.

- Selective separation, for example, copper and nickel.

- Clear, clean water and compact, well-settled sludge that is filterable. With the same starting material, the amount of sludge produced is approximately 1/3 to 1/5, of the sludge produced by hydroxides.

- Despite, the use of an excessive precipitant, no residual sulphide is found in the treated water.

- Cyanide, nitrite, fluoride, sulphite, and free chlorine removal.

- Surfactant and oil separation.

- The COD value is significantly reduced.

- It is ideal for continuous flow systems.

Conclusion

Precipitation is appropriate for the treatment of large volumes of dirty wastewater, because the heavy metals are rendered insoluble by the addition of a precipitation agent, to the wastewater. Sedimentation and filtration can be used to remove the precipitated sludge from the wastewater.

How can we assist?

A wide variety of wastewater treatment options are offered by Netsol Water, including water treatment, wastewater treatment, sewage treatment, effluent treatment, along with advanced physical, chemical and biological methods of wastewater treatment.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.