- For Enquiry- 0120-2350053 || +91 9650608473 || +91 9650795306

- enquiry@netsolwater.com

The essential differences between Sludge thickening and Sludge Dewatering. But before we understand the differences, it is essential to know what their meaning is in the exact sense.

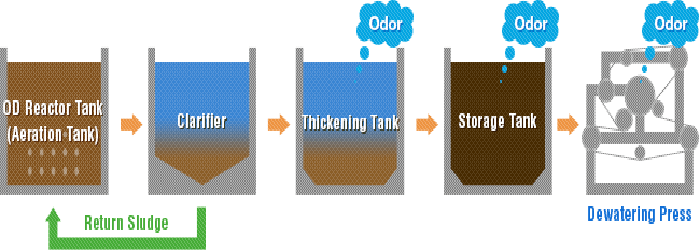

Sludg e thickening is the primary step in sludge treatment. It allows the sludge properly. The main aim of this stage is to reduce the moisture content in the sludge. The sludge contains a high amount of moisture content. Therefore it becomes really necessary to reduce the amount of water content in sludge and thicken and condense it.

Sludge thickening is done using a centrifuge or gravity thickener. It is a small rotating unit that rotates one at a time as a result of which inflow and outflow of water and sludge take place.

Sludge dewatering is making the sludge more condensed and dehydrated so that powder can be produced of sludge and also sludge cake. We can also utilize it as a land filler, for agricultural purposes, and landscaping. In the first step of the sludge treatment process i.e. the sludge thickening process, the moisture content will reduce up to 90%.

The moisture content left needs to be reduced which will be done using the sludge dewatering process. The system used in this process is known as a sludge drying bed. In the dewatering process, both the volume of sludge and moisture content is reduced.

The differences between sludge thickening and sludge dewatering are explained here as below:

|

Sludge Thickening |

Sludge Dewatering |

|---|---|

|

It is the first step in treating the sludge. |

It comes at a later stage in the sludge treatment process. |

|

The main aim of thickening is to reduce the moisture content in the sludge. In this step, up to 90% of moisture content is reduced. |

The main aim is to reduce both the volume and amount of moisture content and organic matter in the sludge. |

|

It produces consistent thickened sludge and prevents cloggings of sludge pumps. |

It helps create cost savings. |

|

It reduces polymer consumption and improves biogas production in an anaerobic digester. |

It helps create cost savings because of reduced polymer consumption and also easy disposal of sludge. |

|

The primary benefit is to improve the operational elements of the plant. |

The primary benefit is to improve the cost-efficiency and reduce the amount of harmful high content organic matters. |

If you have any doubts, please feel free to contact us with your requirements. We can be reached at 9650608473, or feel free to leave your query at enquiry@netsolwater.com.