What is a bio-filtration wastewater treatment plant and how does it work?

Even if the term "bio-filtration" suggests a type of membrane such as reverse osmosis, these systems use bacteria to filter unwanted contaminants rather than simply separating and filtering them, decomposes and runs out of substances. These systems are primarily used in odour control applications and can biodegrade compounds in the gas phase but also in the wastewater treatment that we focus on here.

As already mentioned, bio-filtration uses bacteria to break down pollutants from industrial wastewater. These bacteria are immobilized in a medium that gives them a large surface area to grow. These large surface area media come in many forms.

For example, when sewage bio-filtration was developed at the end of the 19th century, various gravel and crushed stones were used. After developing the use of plastic rings and cardboard appeared. And now, further down, it turns out that porous ceramic media work well for this, especially when used in aquariums or for treating animal waste.

What is bio-filtration in municipal WWT plants?

If organic polluted waste is generated in an industrial or municipal facility, biological wastewater treatment may be suitable for the facility. These systems could be efficient and economical technologies for decomposing and removing organic pollutants from waste such as those found in food and beverage, chemical manufacturing, oil and gas, and municipal industries.

These blocks and materials can be placed in bioreactors and begin to degrade specific compounds from simple proteins, fats, and carbohydrates for food applications to chemical applications where organic amines bind to organic molecules, or ammonia.

In the presence of mercaptan, it is a sulphide bound to an organic compound. In general, bio-filtration is very suitable for all small organic compounds such as all hydrogen’s, sugars, alcohols and aliphatic. Some of these compounds, such as halogenated hydrocarbons and complex aromatic compounds, decompose rapidly, while others decompose very slowly. In these cases, this should be considered when designing the bio-filtration system. Larger bio-filters with longer retention times are needed so that the bacteria can break down harder and on more complex compounds.

General system design

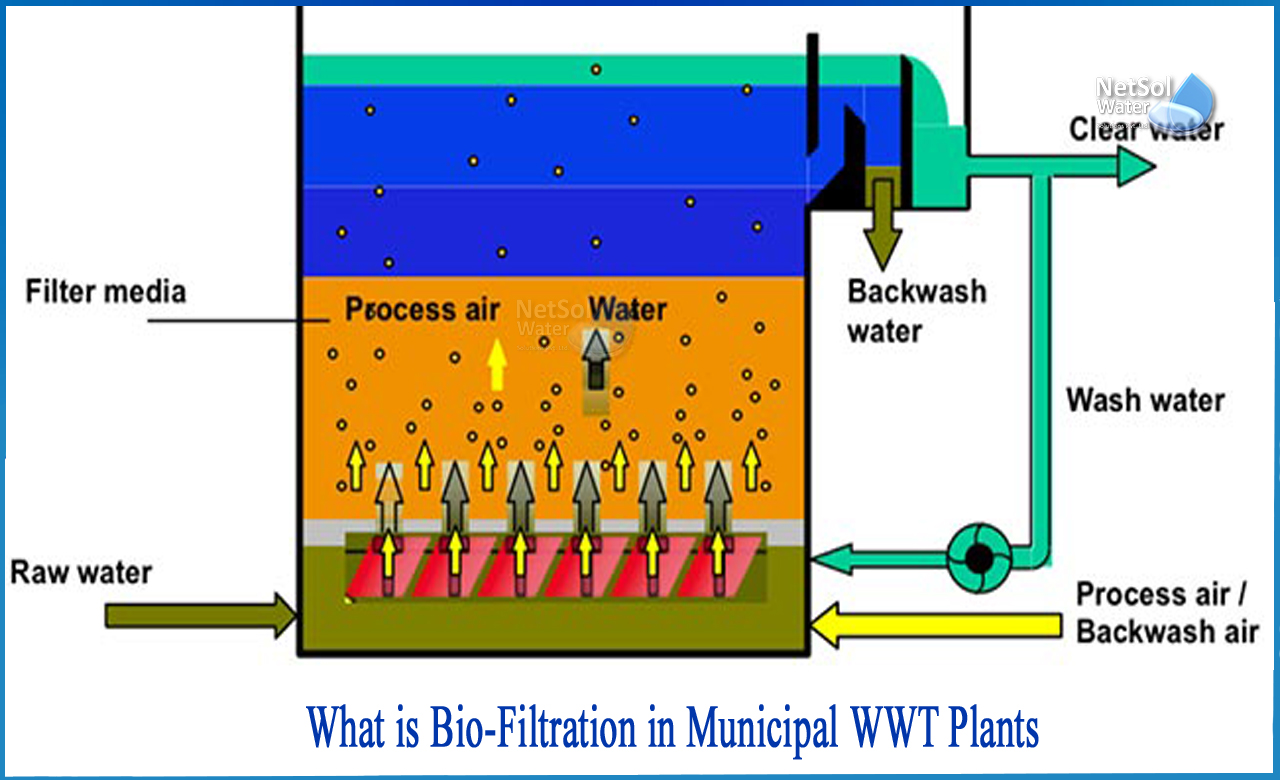

Designing a bio-filtration system is very simple. For example, a sprinkler filter consists of three main components. Water distribution system that evenly distributes wastewater over the entire surface of the bio-filter,the filter medium itself.

This can be any kind of device with a large surface area. An underfloor support system that holds the filter media and provides a slot channel through which gravity drains water. In systems that require ventilation, you typically need to use a blower or fan that turns on automatically when the sensor detects air to bring air into the system. This is usually done through a network of water pipes and flow regulators.

Overall, the system design needs to make sure that the bacteria have everything they need to destroy the pollutants.

They work within the correct pH. You have the right amount of nitrogen, phosphorus, carbon, etc. Your system should be designed to control the environment so that bacteria grow naturally and cope appropriately with pollution. Clean water will come out.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.