What is API for Oil water Separators?

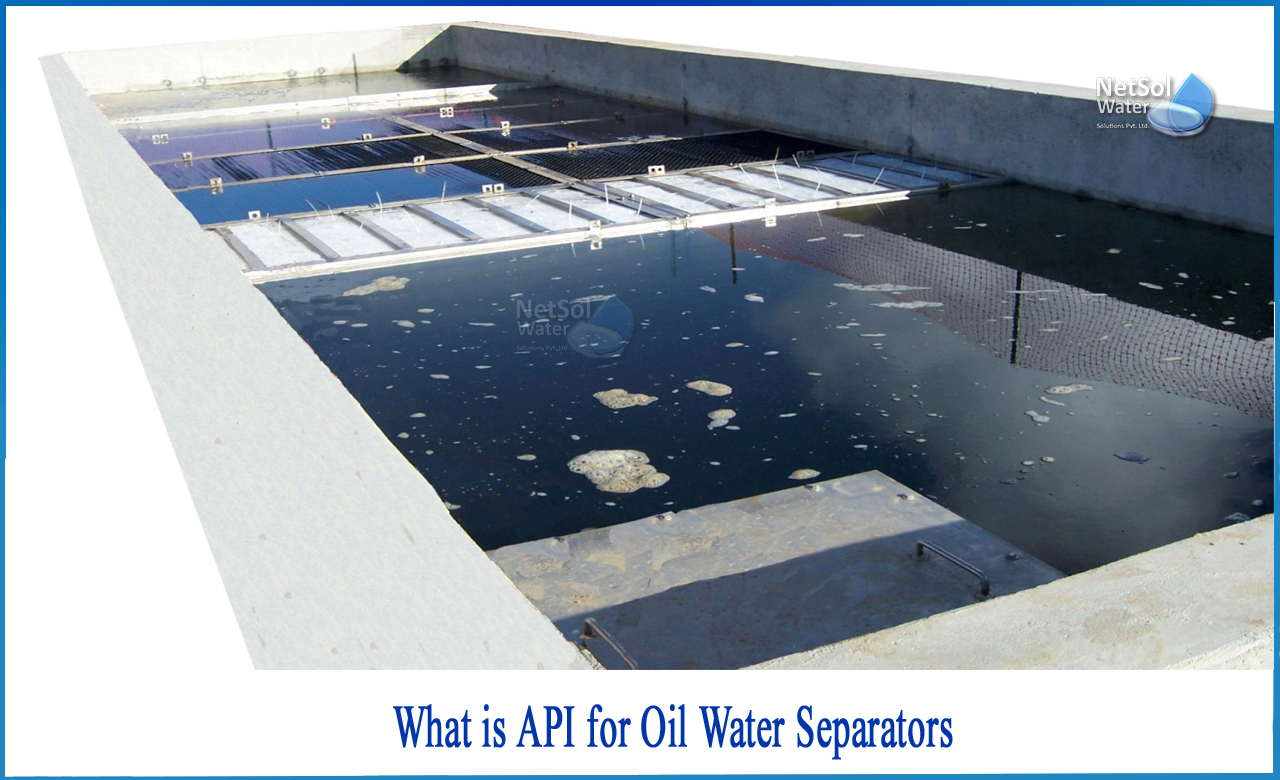

API is a device used to extract oil and suspended particles from wastewater from refineries, petrochemical and chemical industries, natural gas processing facilities, and other industrial sources. The term comes from the fact that these separators are built in accordance with American Petroleum Institute specifications (API).

The API separator was created by the API and the Rex Chain Belt Company roughly 75 years ago. In most petroleum refineries, the API separator is the first and most significant wastewater treatment step. A correctly built API separator's principal role is to separate the bulk of oil and suspended particles from refinery wastewater prior to downstream wastewater treatment.

Although municipal wastewater treatment plants must deal with oil and grease (O&G), this article on oil-water separation is primarily relevant to industrial wastewater systems, especially those linked with petrochemical industries.

Factors having substantial impact on the performance of API

Several factor?s can have a substantial impact on the performance of gravity oil-water separators, including:

1) The wastewater flow rate

2) The oil gravity

3) The pH, and

4) The temperature

For best performance, the design flow rate (velocity through the unit) must be kept near to or below it. When opposed to higher pH (>7), a lower pH (7) improves oil removal. Oil removal via the unit will improve as the temperature of the effluent rises.

Need for API or the importance of API

In most petroleum refineries, the API separator is the first and most significant wastewater treatment step. A correctly built API separator's principal role is to separate the bulk of oil and suspended particles from refinery wastewater prior to downstream wastewater treatment.

Oil can appear in three forms in refinery effluent, and all three forms may be present in a single waste stream. The three types of oil that can be found in wastewater are:

1: Oil that is available for free

2: An emulsion of oil

3: Oil that has been dissolved

Discrete oil globules will rise to the surface of the water due to buoyant forces, forming an oil layer. This makes them reasonably easy to remove in an API separator or in an Equalization tank by skimming them off the surface. Gravity separation, which is what the API separator is built for, may be used to extract free oil. Flow conditions, changes in specific gravity, temperature, and the oil's stability all play a role in its removal.

Oil droplets of a diameter of less than 20 microns, mainly in the 1–10 micron range, make up emulsified oil. Inter-particle interactions dominate buoyant forces in emulsified oil, resulting in a stable suspension in water. Under quiescent circumstances helped by gravity, such as those formed in an API separator, emulsified oil will not separate from the water. Chemical additions such as pH correction or emulsion breakers are required to remove emulsified oil. After being treated in this manner, the wastewater is frequently sent through a dissolved air (or nitrogen) flotation machine to remove the emulsified oil as it separates from the effluent.

Design of an API separator

API separators are designed to reach an oil concentration of no more than 200 ppm leaving the separator, while oil concentrations as low as 50 ppm are frequently achieved. When oil removal through the API is insufficient, a secondary unit process, such as induced gas flotation (IGF) or dissolved air or nitrogen flotation (DAF or DNF), will be used after the API separator to provide a "polishing" step, reducing oil loading to a biological treatment system significantly.

What can we offer?

Conserve resources for the future by partnering with Netsol Water, a well-known water and wastewater management company in Greater Noida. We offer a variety of water and wastewater treatment services throughout India, utilizing the most up-to-date equipment and advanced technologies. We provide innovative wastewater treatment services, sewage treatment plant design, effluent recycling treatment, and a variety of other services. Our water and wastewater treatment systems are highly effective at removing a wide range of chemical, physical pollutants, and biological contaminants.

For further information, call us on +91 9650608473 or email at enquiry@netsolwater.com