What are the Principles of Biological Wastewater Treatment?

The goal of biological wastewater treatment is to remove organic matter from the wastewater that is present in soluble and colloidal form, as well as nutrients such as nitrogen and phosphorus. Microorganisms, mostly bacteria, are responsible for converting dissolved and colloidal carbonaceous organic materials into different cell tissues and gases. In a settling tank, cell tissue with a higher specific gravity than water may be removed.

As a result, unless the cell tissues are removed, comprehensive wastewater treatment will be impossible. The biological elimination of degradable organics entails a series of stages that include mass transport.

Transfer, adsorption, absorption, and biochemical enzymatic reactions are all examples of biological enzymatic processes.

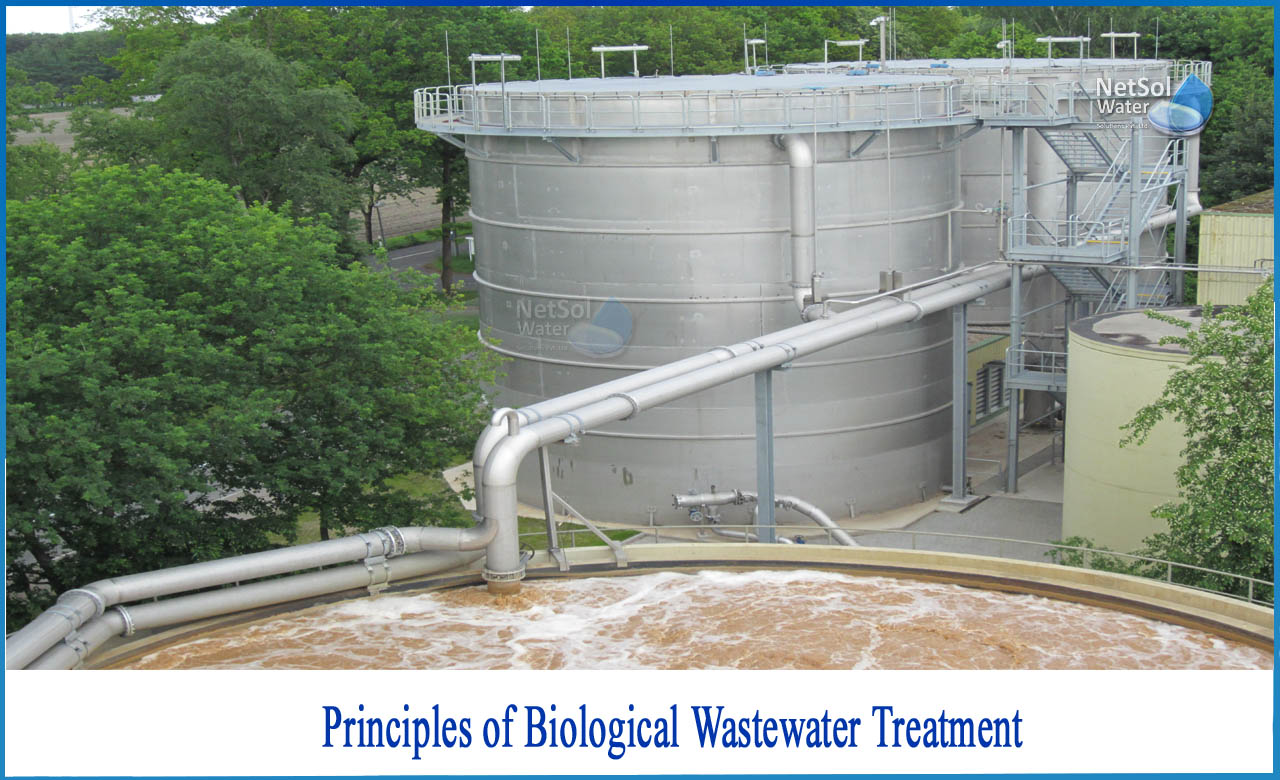

Biological wastewater treatment principles

The soluble organic compounds in wastewater are entirely eliminated by biological oxidation under ideal environmental circumstances; some of it is oxidized, while the balance is turned into biological mass in biological reactors. The metabolic end products are either gas or liquid; on the other hand, the generated biological matter may readily flocculate and be filtered out in clarifiers.

As a result, the biological treatment system is generally made from

(1) A biological reactor; and

(2) A sedimentation tank for removing the sludge generated by the biological reactor.

The type of reactor used, as well as the ambient conditions, will influence microorganism growth and the pace at which the substrate is consumed over time.

This can be represented individually as:

1: Batch reactor

If the microorganisms injected in the reactor are not suited (acclimatized) to the kind of wastewater being treated, there may be a lag period during fresh reactor commissioning. There will be some lag time before the bacteria takes the substrate, which will reflect in substrate depletion and microbial growth during this period.

Log growth phase

In this phase, the substrate is sufficient, and the pace of metabolism is solely determined by the microorganism's capacity to utilize it.

Declining growth phase

Due to a lack of substrate, the rate of metabolism and, as a result, the pace of growth of microorganisms slows down. This is referred to as a substrate restricted growth state, in which the substrate provided is insufficient to sustain the microorganisms' maximal growth rate.

Stationary phase

When the bacterial growth and decay rates are equal, there is no net gain or reduction in the mass of the microbe.

Endogenous growth phase

Microorganisms oxidize their own protoplasm for energy (endogenous respiration), resulting in a reduction in their number and bulk.

2: Continuous System

The rate of metabolism in a continuous system is controlled by the "Food to Microorganism" ratio (F/M).

-Low F/M indicates that there is less food available, resulting in endogenous microbial development.

-For a high F/M, the food supply is plentiful, hence the growth phase is a log growth phase. Between the two growth phases, the pace of growth will slow.

The biological reactors are usually run in a falling growth phase or an endogenous growth phase with a high enough F/M ratio to keep the microbe mass steady and not depleted. The settling qualities of sludge formed in the log phase are poor, but sludge created in the endogenous phase have superior settling properties, settles well, and is more stable.

Choosing the Most Appropriate Wastewater or sewage Treatment System!

When selecting a system, there is a lot to consider, so it is critical to do some research.

An ideal system is one that will withstand the test of time while requiring minimal initial and ongoing costs. At Netsol Water Solutions, our sewage treatment systems have proven to withstand the test of time while remaining very affordable.

It goes without saying that a system must meet current public and environmental health and safety standards and regulations. Our sewage treatment systems are built to the highest standards and have the least amount of environmental impact.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.